I am trying to compare the airflow of two potential designs, neither of which is complicated.

These screenshots are of sections from a larger assembly.

These sections are only ~25% the size of the full assembly.

The geometry shown is the air volume around the material with 12" of space on either side of the geometry being tested.

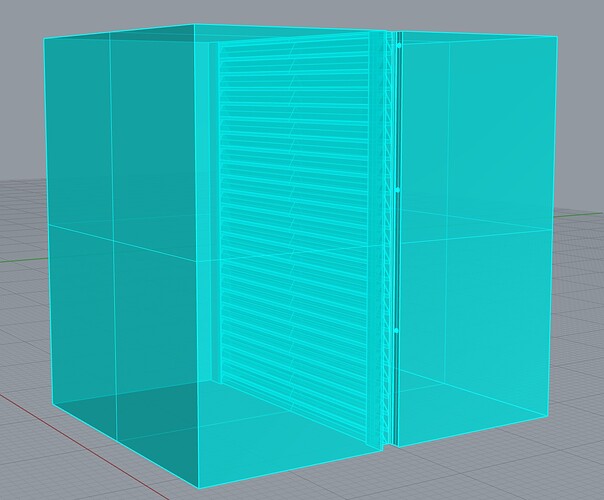

Design 1 - “Louvers”

Failed to complete, simply timing out after 5.5 hours. I would have gladly let the simulation continue running, but it auto-canceled rather then allowing me the option of expending the time required.

After rerunning with a time out of ~10x the default simulation time, the simulation failed with a “divergence” error.

Geometry:

Valid polysurface.

closed solid polysurface with 1635 surfaces.

Edge Tally:

3645 manifold edges

Edge Tolerances: 0 to 0.00776457

median = 0 average = 5.30483e-05

Vertex Tolerances: 0 to 0.00777234

median = 0 average = 4.85417e-05

Render mesh: 1635 meshes 59387 vertices 53718 polygons

Created with quality meshing parameters.

Analysis mesh: none present

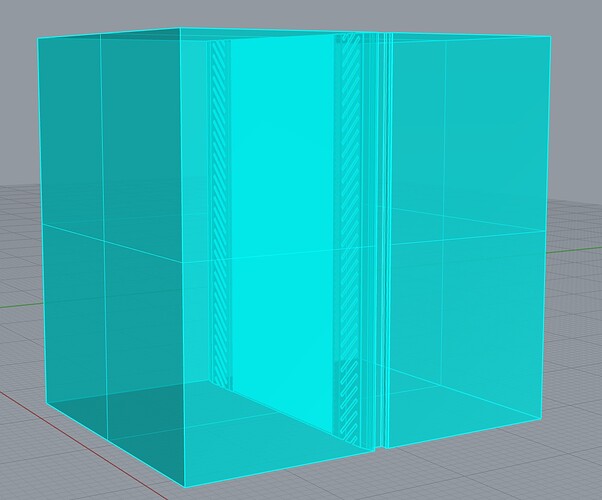

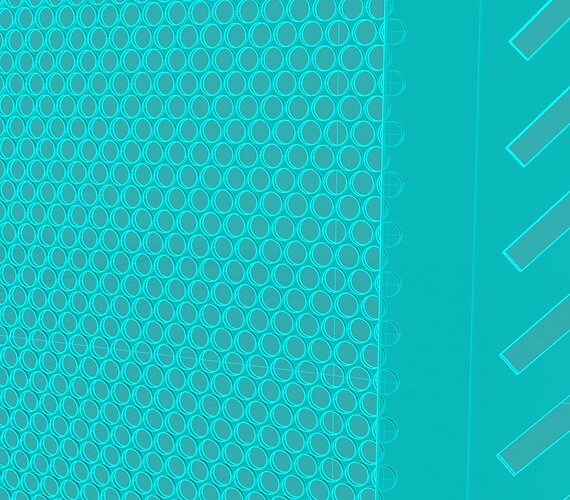

Design 2 - “Mesh”

For this design I have not even been able to complete the upload step.

Geometry:

Valid polysurface.

closed solid polysurface with 7683 surfaces.

Edge Tally:

7119 seam edges

16430 manifold edges

= 23549 total edges

Edge Tolerances: 0 to 0.0167974

median = 0 average = 0.000147589

Vertex Tolerances: 0 to 0.00997248

median = 0 average = 5.62939e-05

Render mesh: 7683 meshes 1834892 vertices 1383917 polygons

Created with quality meshing parameters.

Analysis mesh: none present

Thus far I have been unable to complete a simulation of either of these designs.

While I was able to complete a smaller 12"x12" sample of each design those tests yielded to little data to be representative of the larger assembly.