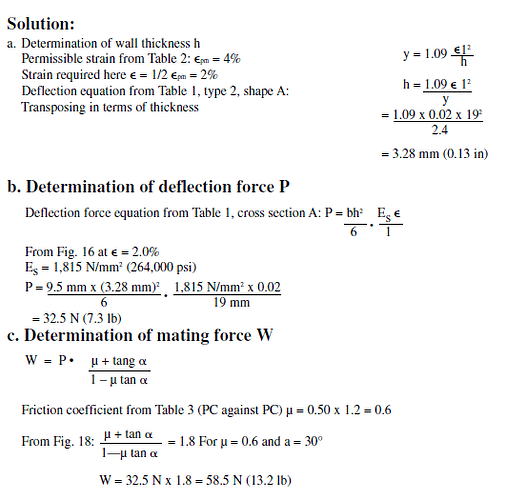

So basically what I have done here is, I tried to validate the Hand Calculations of a tapered Snap Fit Hook provided in this Plastic Snap Joints for Plastics by Bayer Material Science [1], by using SimScale FEA solver MUMPS.

My Public Project Link SimScale

Physical Problem:

Given:

a. Material = Makrolon® polycarbonate

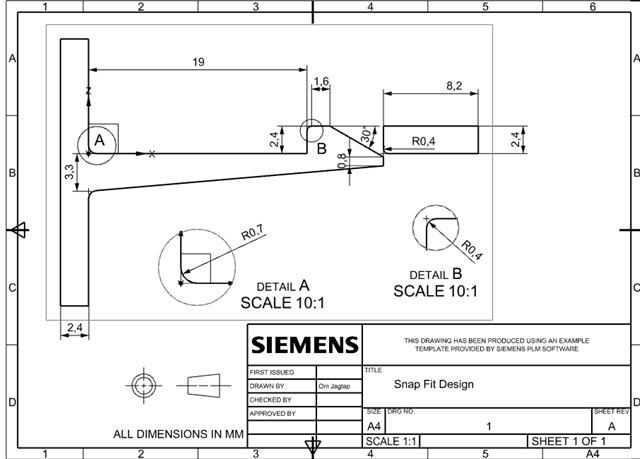

b. Length (1) = 19 mm (0.75 in)

c. Width (b) = 9.5 mm (0.37 in)

d. Undercut (y) = 2.4 mm (0.094 in)

e. Angle of inclination (a) = 30°

Find:

a. Thickness h at which full deflection y will

cause a strain of one-half the permissible

strain.

b. Deflection force P

c. Mating force W

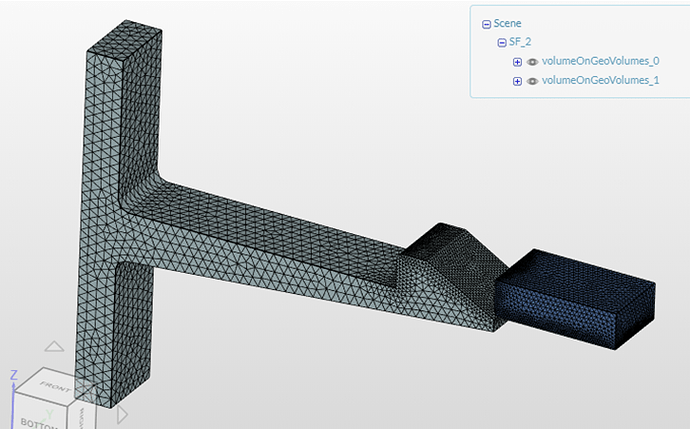

Geometries

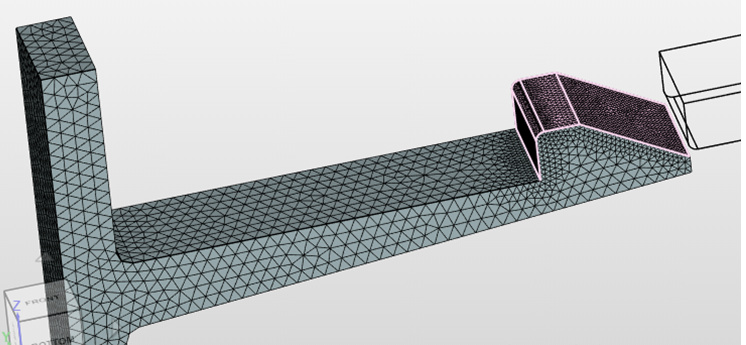

Meshes

Geometry was meshed in SimScale using the tet-dominant mesh. Added Mesh Refinement in areas of contact and other required once as per results.

Simulations

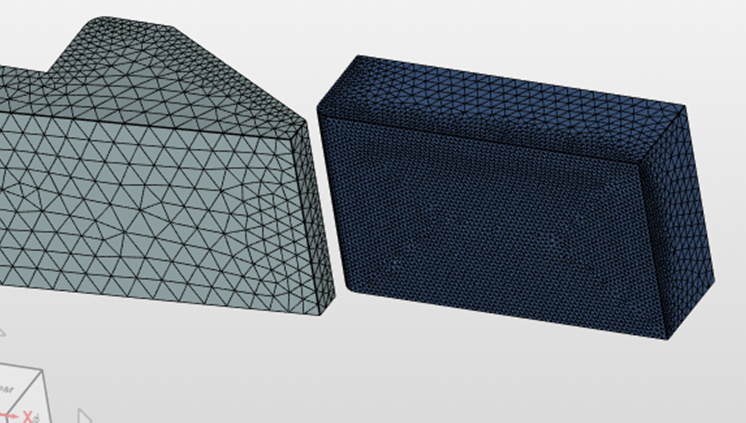

Simulation Setup used is Static Analysis with nonlinearity set to True. By providing physical contact between two bodies block and snap.

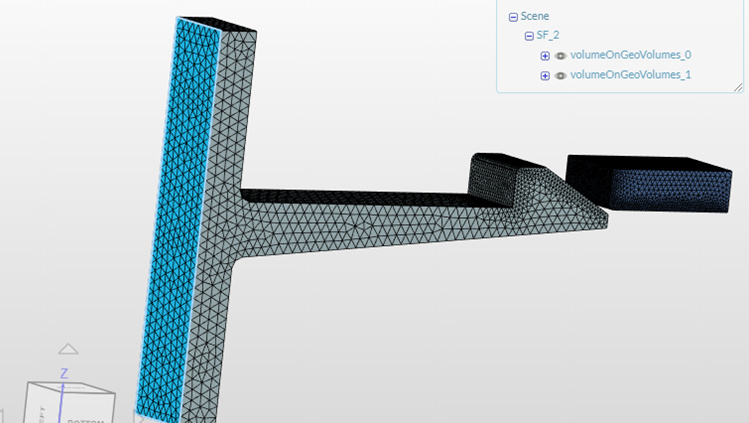

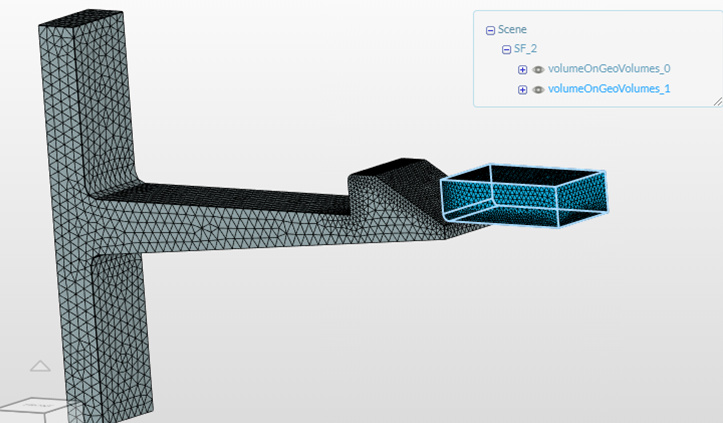

Providing Master surfaces as:

And Slave Surfaces as:

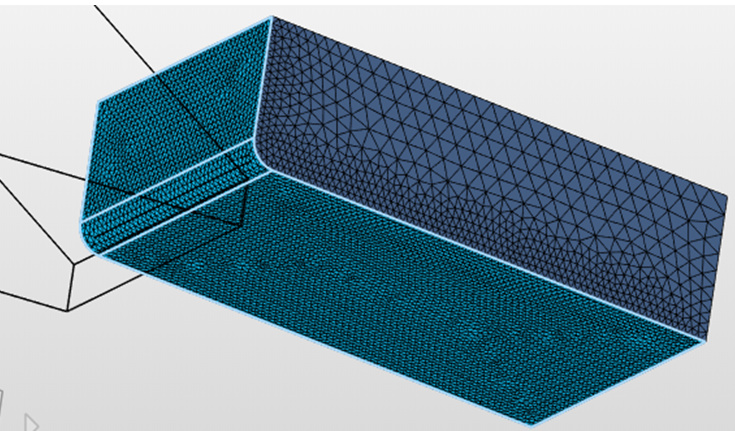

Displacement boundary condition provided in the X direction as 0.016*t.

For the simulation setup, a fixed boundary condition was applied to the small box against which the body deforms.

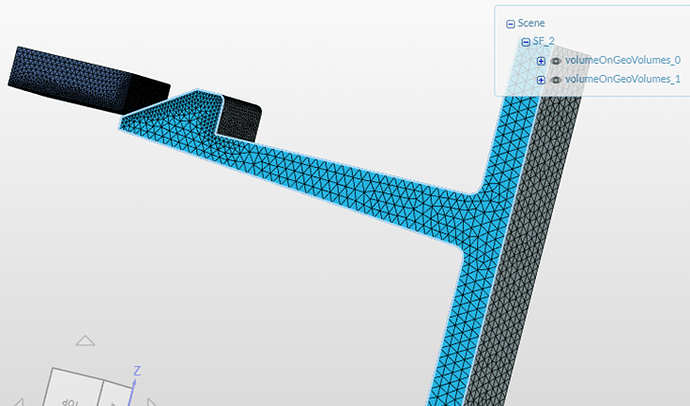

And symmetry condition on the shown surface to decrease computational time and load over solver.

Encountered Results:

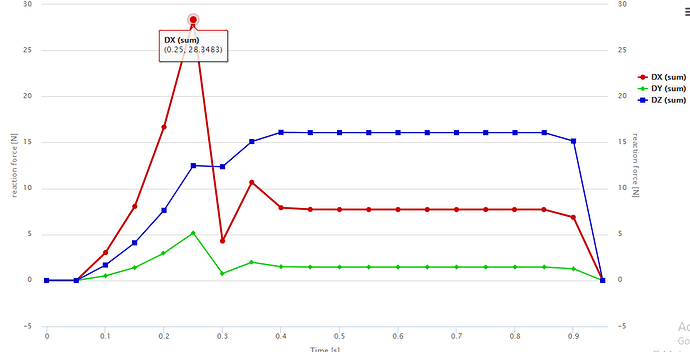

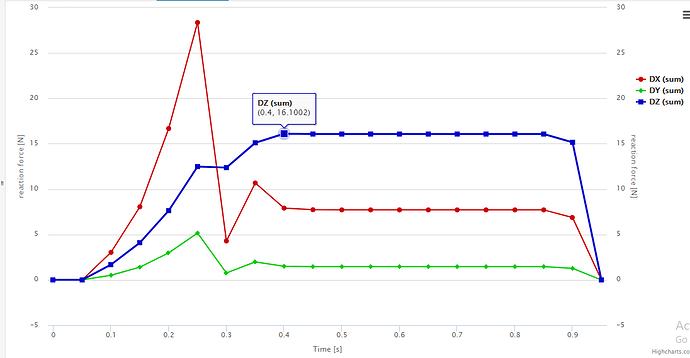

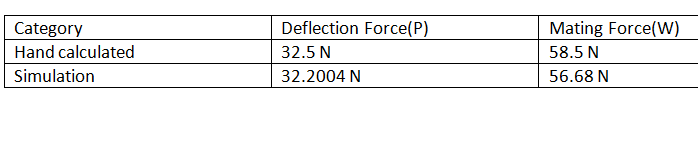

Mating Forces (W in Paper) : 28.34*2= 56.68N

Deflection Force(P in Paper) = 16.1*2 = 32.2004N

Results almost match the hand calculated data.

[1] Plastic Snap Fit Design, http://fab.cba.mit.edu/classes/S62.12/people/vernelle.noel/Plastic_Snap_fit_design.pdf

[2] Smarter Snap-Fit Design using FEA, Webinar recording, Smarter Snap-Fit Design using FEA Simulation - YouTube