Hi, my name is James, and I’m the Technical Director of Mitre Racing, an F1 in Schools team operating out of The Bishop’s Stortford High School in the UK. Recently, at the London North Regional Finals, we set the fastest time of any team in the UK this season - a 1.099 second run that places us firmly amongst the top teams in the country. This combined with a ‘Best Engineered Car’ award to complete a highly successful first outing for the school’s first team.

But what was so special about our car and its development process? Well, without access to a (costly) test track, the Mitre Racing MR-01’s first-ever test run was…in competition. In fact, our physical testing was limited to rolling the final car along the floor to check that the bearings were functioning correctly, at which point the car was packaged and shipped. Pretty high-tech, right?

With such limited capacity and funding for physical testing, we had to make sure that our performance and reliability could be accurately quantified in a virtual environment before we committed to manufacturing. Our simulation package of choice also needed to be suitable for a fast-paced iterative environment, where time equates to performance. Additionally, without powerful local processing capabilities, cloud-powered solutions became a necessity for us. The project requirements of accuracy, speed, and accessibility could only be met by SimScale’s software. An extra benefit of this simulation package for us was the ease of use of the platform, with well-developed forums and UI at the center of the overall environment.

During our development process, we utilised both CFD and FEA simulations in order to maximise both the performance and strength of the car in a racing scenario. The result was a structurally sound car layout that allowed peace of mind when sending the cars to race, combined with a high-performance aerodynamic package.

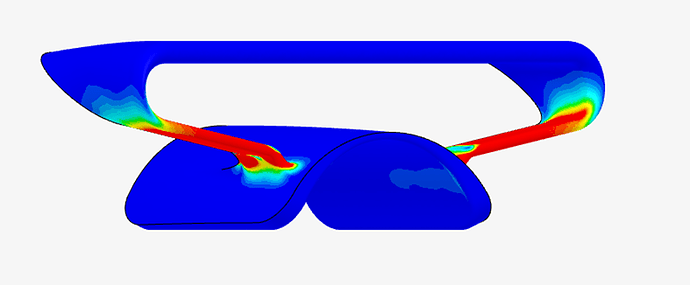

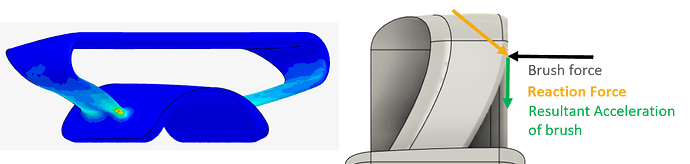

One example of our development process lay in the rear wing’s supports. The strength requirement here is far greater than for many other components, as the rear wing absorbs much of the decelerative force at the end of a race. A proprietary brush system is used to stop the cars in competition, which often causes breakages - even at the world finals. We used car mass, velocity, and the deceleration times of other teams to estimate the maximum possible force acting on the rear wing; around 20N. This value was then used in an FEA simulation to determine if our supports would break under such a force. We input data on our chosen material, PA2200, and ran the simulation. Our post-processing indicated that breaking stress would be exceeded in the supports:

The major issue facing wing strength was a moment about the wing mounting points, caused by the brushes pushing on the wingtips. This was dangerous to our 3D-printed parts, meaning that the goal of our redesign was to reduce the moment’s strength, while also taking advantage of the multi-directional strength provided by SLS 3D printing. We developed swept-back supports to turn a component of the distributed brush force into a compressive force, by changing the angle to the support at which the force acts. The angled design encouraged the bristles to slide down the support, reducing the moment caused by the brush about the wing mounting points. This meant that only a small amount of material needed to be added to strengthen them sufficiently. The result was a wing with 32% less frontal area than our baseline part (and a similar drag reduction), improving performance while also ensuring reliability. Retesting the part with FEA proved that the new design was far stronger under the same conditions as the previous simulation, so we finalised the wing in this configuration for manufacture. Our chosen simulation environment allowed us to be certain that the wing supports would not break during racing - a theoretical certainty that became reality when we suffered a total of zero breakages during racing at the regional finals.

This is just one example of the development opportunities which were allowed by the SimScale platform. FEA was used again throughout the project - for example when checking the strength of our wheels, which rotate at up to 15,000 RPM. CFD was utilised at every design iteration to ensure that our development ideas would transfer into performance on the track. This included the development of our front wing, which is a regulatory component that acts as a vital flow conditioning device for the rest of the car.

This January, we’ll be returning to competition at the UK National Finals, which this year will be held at the Birmingham NEC during the Autosport International show. The MR-01 will be racing again, taking on the best teams in the UK at both time trial and head-to-head racing, while a reshuffled Mitre Racing team will be positioned alongside our display booth throughout the weekend. We hope to see you there, and until then you can keep up to date with our progress via our Instagram channel:

Follow the Mitre Racing Instagram page

Thank you for reading,

James Petty

Technical Director

Mitre Racing

james@mitreracing.org