Description

Forced-air cooling (FAC) efficiency of fruit packed in ventilated cartons can be considerably improved by revising vent hole design and tailoring these openings according to the internal packaging used. Current vent hole designs for fruit cartons, however, often result from trials and errors or are developed in order to improve a specific package functionality, such as fruit cooling rate. In this project you will need to use CHT simulation to evaluate the impact of internal trays and vent hole designs. One design has already been used in commercial export of apples, while the other three are new configurations proposed to improve fruit cooling efficiency.

Imput Data

Carton Geometry:

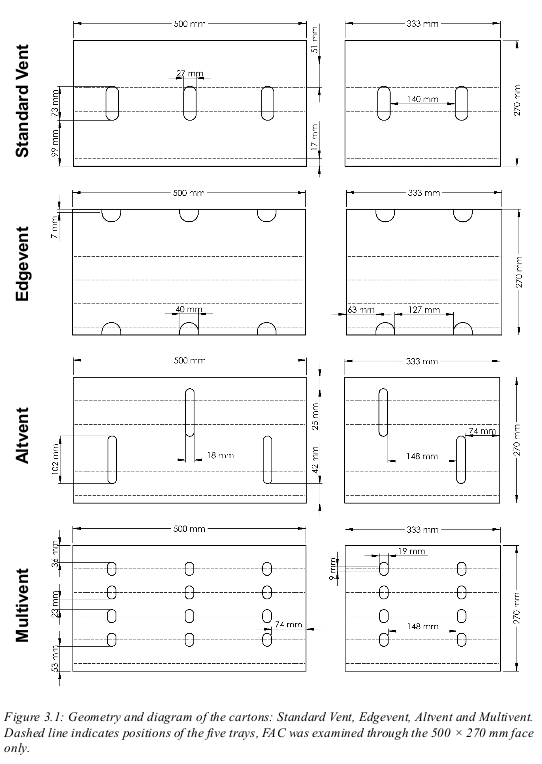

Four vent hole designs were evaluated for a telescopic carton (500x333x270 mm) with the same geometrical dimensions (figure 3.1).

Operating conditions:

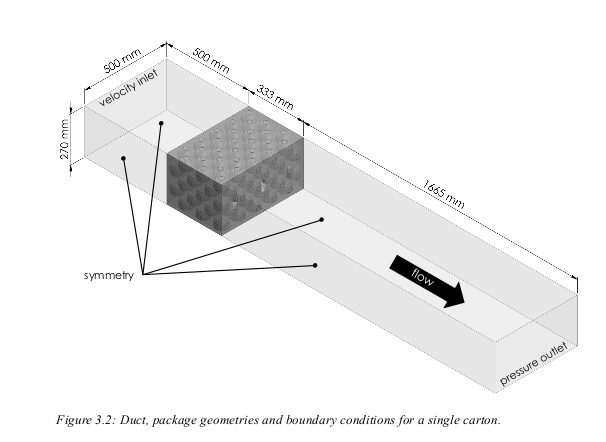

Horizontal airflow, as induced in FAC conditions, was evaluated through the four carton desings (with and without trays) using CFD. The duct and package geometries, as well as the CFD models are shoen in Figure 3.2:

Individual apple fruit were modelled as spheres (Ø72.36 mm), with each carton holding 150 fruit packed across 5 layers of trays using stagged packaging configuration. Fruit volumes were trimmed by 2.5 mm at points of contact with other fruit, trays and the carton walls to facilitate meshing.

The inlet boundary condition were set as a uniform velocity inlet, with low turbulence intensity (0.05%). Three airflow rates were evaluated, namely 0.33, 1.00 and 3.00 L s -1 kg -1, which are represetative for FAC flow rates in reality. Reynolds numbers for flow inside the carton thus ranged between 380 and 4100, indicating both transitional and turbulent flow regimes. The inflow air temperature was set to -0.5 °C, as used in the pome fruit industry. The ambient atmospheric pressure was set at the outlet boundary condition.

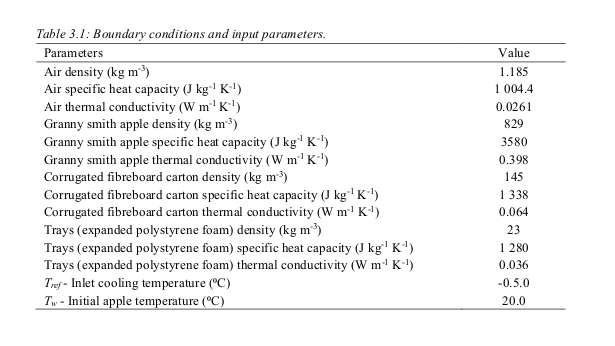

Thermal properties are shown in the next table:

Purpose

The purpose of this project is to validate the accuracy of the SimScale CHT solver for thermal packaging problems.

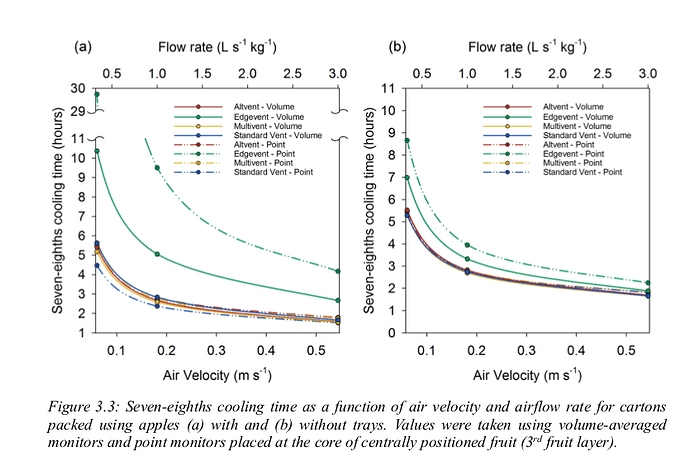

The Seven-eights cooling time (*) as a function of air velocity and airflow rate for cartons packed using apples must be compared with the proposed one as in the figure below:

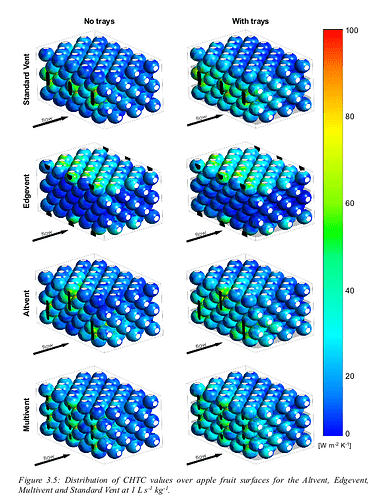

The distribution of CHTC values over apple fruit surfaces must be compared with the ones proposed in the figure below:

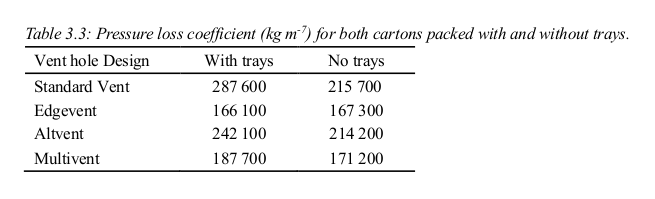

Pressure loss coefficient must be compared with the ones proposed in the table below:

(*) Seven-eights cooling time is the time required for fruit to cool to seven-eights of the original difference in temperature between the fruit and the cooling medium

Key Words

Computational fluid dynamics, CFD, CHT, Thermal packaging, fruit cooling.

Reference

http://ir.nrf.ac.za/handle/10907/1241 (Chapter 3)

Status

Not started yet