Analysing a Wing Section

When analysing a wing section, we are usually interested in these few things:

- Coefficient of Lift

- Coefficient of Drag

- Most efficient angle of attack

- Angle of stall

- Stall characteristics

All this can be studied in CFD and is usually preferred over experimental studies as CFD tends to be less time consuming and easier to gather and analyse the information.

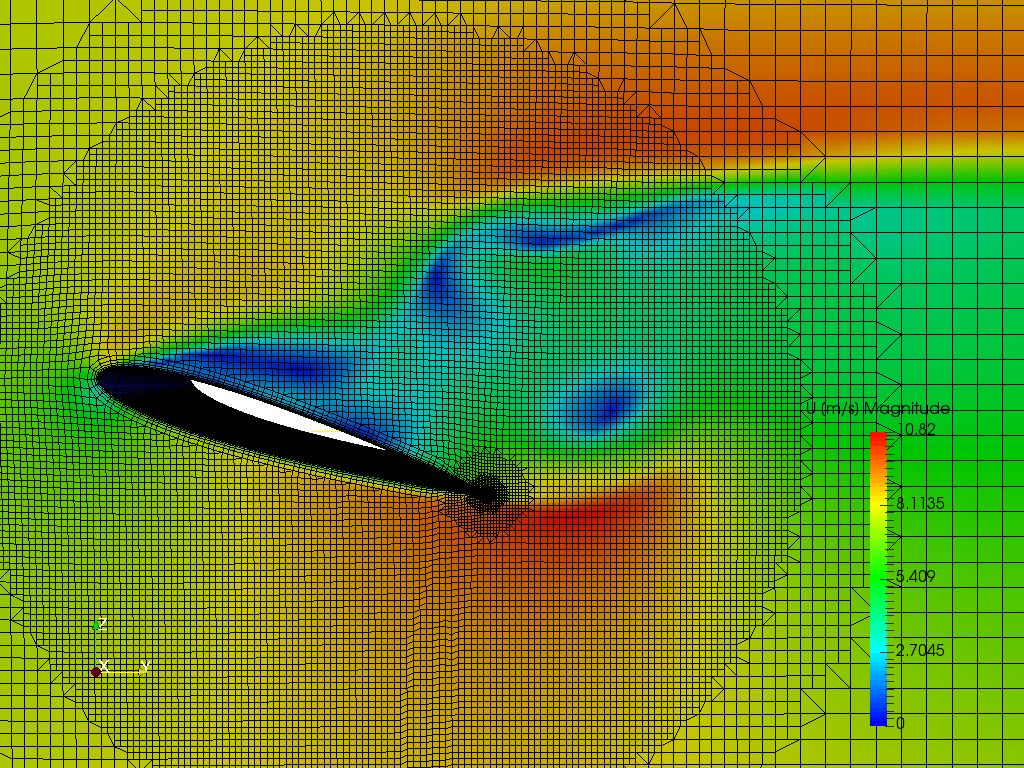

Stall Characteristics

It is recommended to start simple and build up when a good setup is achieved, however when high flow separation occurs (i.e. around and after the stall point) certain phenomenon’s will take place making your results inaccurate and sometimes stop convergence of a steady state simulation. The main reason for this is vortex shedding, experimental results would be taken when the flow was fully developed. If convergence is reached it is likely to converge at the point before vortex shedding. This means to analyse the stall characteristics you are likely to have to run a transient simulation, this is by nature very computationally expensive.

An unconverged steady state simulation after stall

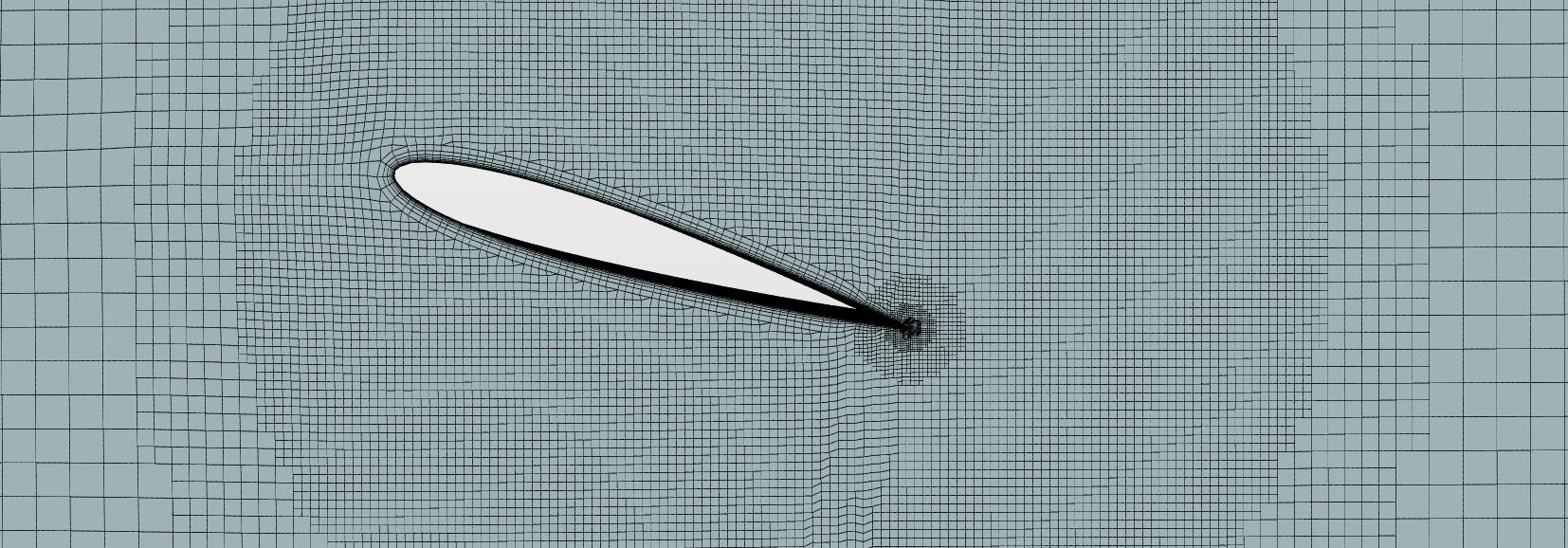

Setting Up a Mesh

here are two approaches that might be used when setting up a mesh in SimScale.

The first approach is best used when velocity is fairly low, a mesh can be generated to serve the analysis of the aerofoils at all angles of attack. This method involves importing the geometry at a zero angle of attack, creating sufficient mesh around the aerofoil to allow for varying flow directions. This way instead of varying the geometry and re-meshing we simply change the flow angle.

The second (the method I used in the RANS & LES comparison) is to vary the geometry and re-mesh with the same setting each time angle of attack changes, this seems a lot of work however at high velocities we can ramp the inlet velocity. There is also the advantage that the mesh will be aligned with the flow direction.

Setting up the simulation

This is a fairly simple setup, the only complications are the inlet/outlet boundary conditions, you can define these conditions as freestream velocity conditions or custom inlet-outlet velocity. The result control item Force Coefficients will need to be set and it also useful to set y+ control item as well to ensure the boundary layer has been sufficiently resolved.

Matlab code for quickly calculation velocity, lift and drag vectors

velocity = 97.1265;

angle = 17;

xVelocity = 0;

yVelocity = velocitycosd(angle);

zVelocity = velocitysind(angle);

x_Lift_Direction = 0;

y_Lift_Direction = cosd(angle+90);

z_Lift_Direction = sind(angle+90);

x_Drag_Direction = 0;

y_Drag_Direction = cosd(angle);

z_Drag_Direction = sind(angle);

Velocity = [xVelocity,yVelocity,zVelocity]

Lift_Direction = [x_Lift_Direction,y_Lift_Direction,z_Lift_Direction]

Drag_Direction = [x_Drag_Direction,y_Drag_Direction,z_Drag_Direction]

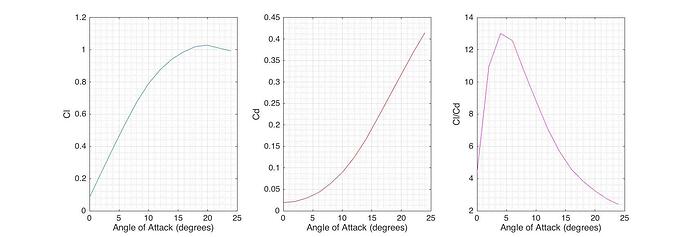

Method of Gathering Data

Every angle of attack will need to be run to record the Coefficient of lift and drag if the aerofoil has a camber negative AoA’s might need to be run. The data can be visualised (using excel or Matlab) to easily show the characteristics of the aerofoil.

Matlab code for plotting data

%AoA , Cl, Cd

wingData=[0, 0.0840, 0.0193;

2, 0.2378, 0.0217;

4, 0.3905, 0.0300;

6, 0.5380, 0.0428;

8, 0.6753, 0.0635;

10, 0.7900, 0.0895;

12, 0.8773, 0.1240;

14, 0.9430, 0.1664;

16, 0.9882, 0.2161;

18, 1.0204, 0.2669;

20, 1.0286, 0.3178;

22, 1.0097, 0.3686;

24, 0.9925, 0.4148]

%Cl/Cd

wingData(:,4)=wingData(:,2)./wingData(:,3)

%Plot on 3 Graphs

figure

%Cl v AoA

subplot(1,3,1)

plot(wingData(:,1),wingData(:,2))

xlabel(‘Angle of Attack (degrees)’)

ylabel(‘Cl’)

grid on

grid minor

%Cd v AoA

subplot(1,3,2)

plot(wingData(:,1),wingData(:,3),‘r’)

xlabel(‘Angle of Attack (degrees)’)

ylabel(‘Cd’)

grid on

grid minor

%Cl/Cd v AoA

subplot(1,3,3)

plot(wingData(:,1),wingData(:,4),‘m’)

xlabel(‘Angle of Attack (degrees)’)

ylabel(‘Cl/Cd’)

grid on

grid minor

The above image shows information of the aerofoil characteristics mainly before stall, It also shows the most efficient angle of attack, this occurs when Cl/Cd is at its maximum.