As described in the documentation page for the bolt preload boundary condition, the fastener shank geometry must be simplified into cylindrical surfaces. Also, small chamfers leading into the nuts and bolt heads should be removed and all parts should be cleanly imprinted to one another.

Fortunately, all of these tasks can be performed using the various geometry prep tools available within the SimScale CAD Mode so you do not need to modify your design model in your CAD package.

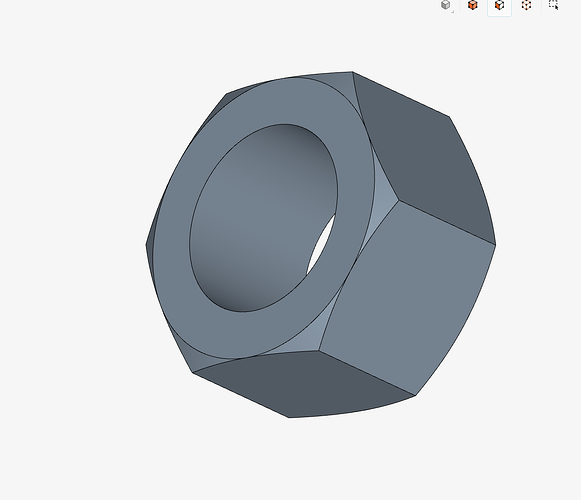

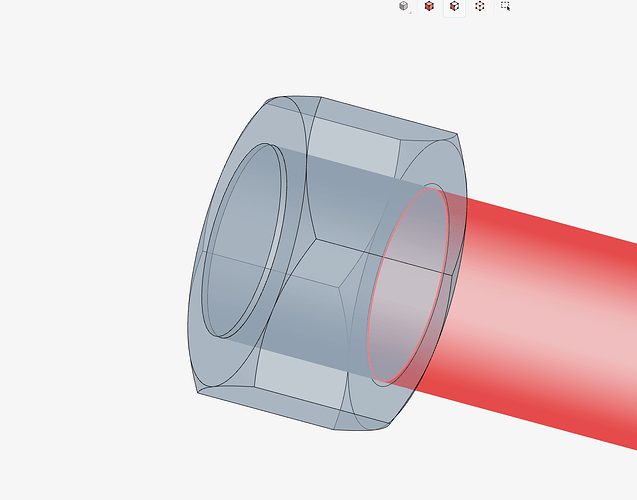

Let’s consider the following typical nut and bolt combo:

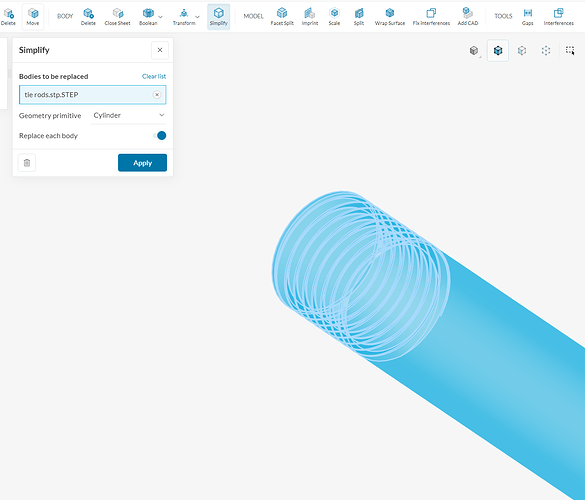

The threads on this fastener pair need to be removed in order to properly simulate this component. Let us first consider the bolt. In the SimScale CAD mode, the “Simplify” body command can automatically represent this bolt as a simple cylinder:

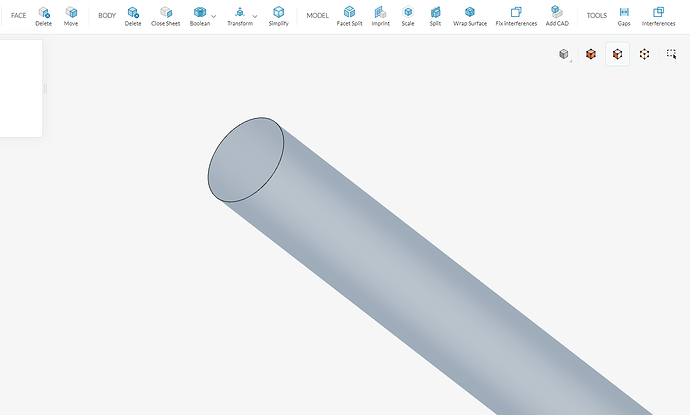

This is the resulting part:

Then, the boolean subtract body operation can be used to eliminate most of the threads from the nut:

The remaining thread surfaces can be dealt with using the Delete (Face) operation:

This leaves us with a clean threaded surface of the nut:

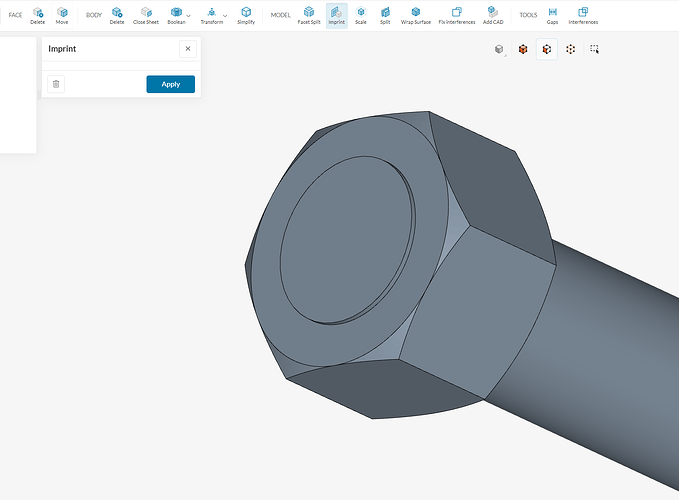

Finally, the imprint operation can be used to topologically split any mating faces for contact and BC purposes. Note that this is a global operation, so it should be done as a last step once all fasteners are prepped:

Here is the resulting, fully prepared fastener pair:

From here out, the components can be modeled using contacts and the bolt preload BC in your structural finite element analysis.