Good day, is there a way to simulate self-weight only in FEA? We are decommissioning a corroded silo & we need to make an informed decision on the lifting method based on the measured thickness.

Hi @mvusi,

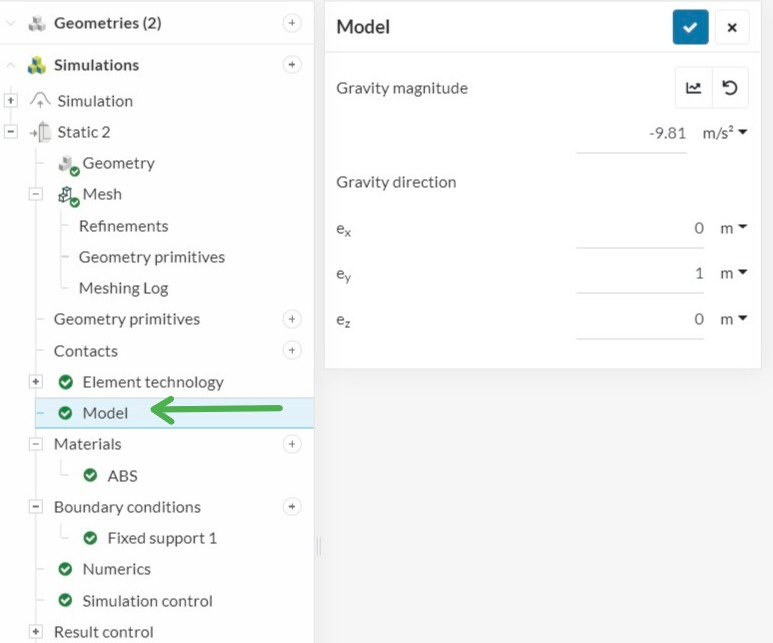

Yes, this is possible. The image below shows where to turn on gravity.

Good Luck,

Christopher

Thank you so much, so no force inputs, right? If so, how to assess buckling due to this loading?

Hi @mvusi,

If you are just interested in the structure under its own weight then do not add force inputs.

Simscale does not have a Buckling module but you can perform a similar analysis using the nonlinear option.

Christopher

Thanks. We need to be aware of the critical thickness that would permit use of lifting lugs without buckling, should I ramp up gravity or density during non-linear analysis?

Hey @mvusi!

What you can do instead of using the classical Euler buckling formula is to use the one for self-buckling. This formula has the information of the thickness explicitly included.

As @cjquijano already mentioned there is no buckling module implemented yet so if you want to see the effect on self-buckling a small lateral and axial force would probably be necessary to see some sort of buckling behavior. Maybe @BenLewis and @rszoeke can give you additional hints here.

Cheers!

Jousef

As already mentioned, SimScale does not currently support buckling analysis. There is the option of doing a nonlinear study, but, in this specific case, I would not recommend it because of the geometry of the silo structure. It is very large with comparatively thin walls. For this type of structure shell elements are required. Unfortunately SimScale does not currently support shell elements.

Can you describe your application in more detail? How do you plan on lifting the silo? How do you see the silo buckling? I imagine the silo has a cone roof and you are planning on lifting it with a single pick point in the center of the roof. Your concern is that the roof might buckle and allowing the walls to collapse inwards. Is this correct?

Thanks for again mentioning the silo itself! Still had the legs in mind, in this case the formula used by me is certainly not applicable for this case ![]()

Feel free to give your votes to the feature requests mentioned by Ben here:

Cheers,

Jousef

Thank you so much for the feedback. We are planning on attaching two lifting lugs on the vertical segments of the silo, 180degree apart. The top of the roof has sections which are worn out completely & can’t be used at all. My concern is the failure from the lifting points or collapse of the corroded shell during lifting process. The only area we are certain has been protected against corrosion is the hopper but we can’t use this point as the whole silo will have to turn & this will give us issues.

Can you use a spreader bar above the silo? If I understand your problem correctly this will prevent the roof from collapsing.

I’m a consultant in this project & my client have long planned to use lifting lugs however the issue is that of the corroded members, hence the strategic question.

I sorry, I still don’t understand the problem. If you’re planning on lifting the silo from lifting lugs attached to the top of the barrel, where do you foresee a buckling issue?