Defining elastoplastic material is fairly simple in SimScale thanks to table upload. You can define such type of material by just uploading a .csv file containing the strain values in first column and dependent stress values in second column distributed by a delimiter (compatible: comma, semicolon, tab, space). A step by step guide below shows how to do that considering a material whose Young’s modulus (E) is dependent on temperature:

-

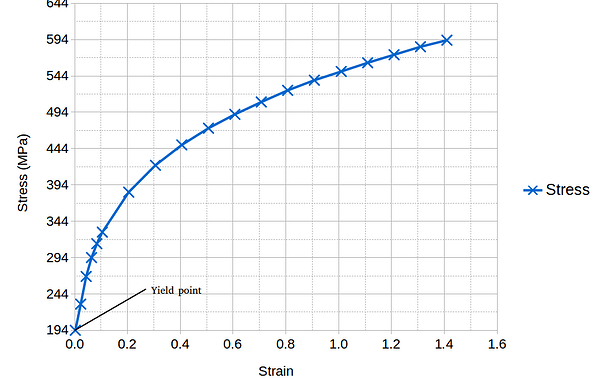

Using your material stress-strain data, make a a .csv file. The graph below shows an example of an elastoplastic Aluminum stress-strain data curve.

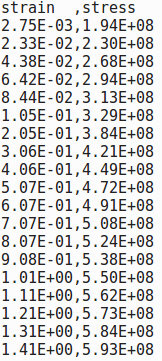

Using this material data (since solver takes first value as a yield point value), one can create a comma delimited .csv file which will look like in any text editor as:

-

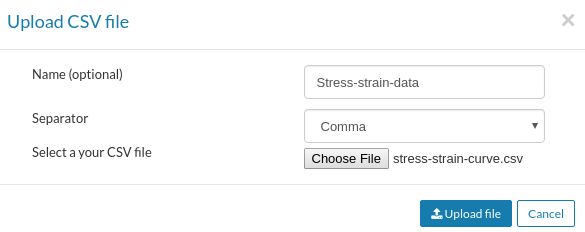

Upload the table to a nonlinear static or dynamic analysis -advanced by creating a new material, switching Material behavior to Plastic, clicking table upload button (

) under von Mises stress and than click upload file (

) under von Mises stress and than click upload file ( ). A Upload CSV file window will pop up as shown in the figure below. Click Choose file and select your material file. Give it a name (optional). Next click Upload file.

). A Upload CSV file window will pop up as shown in the figure below. Click Choose file and select your material file. Give it a name (optional). Next click Upload file.

-

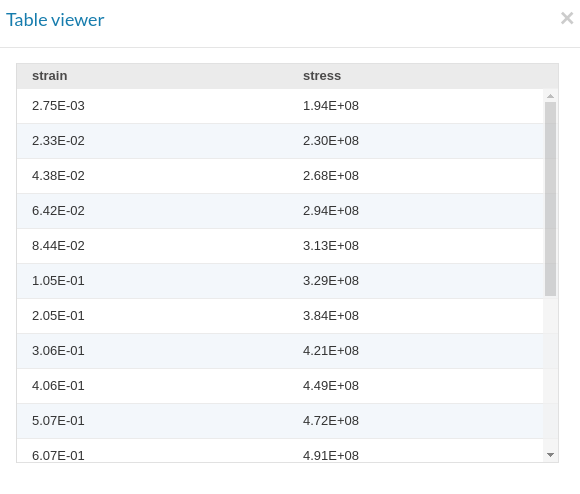

Click

button to see the uploaded data whose column should look well separated as shown in the figure below (if both column values are not separated than it means that the selected Separator (delimiter) wasn’t right at the time of upload e.g. using Semicolon as separator for file having column separated with Comma).

button to see the uploaded data whose column should look well separated as shown in the figure below (if both column values are not separated than it means that the selected Separator (delimiter) wasn’t right at the time of upload e.g. using Semicolon as separator for file having column separated with Comma).

-

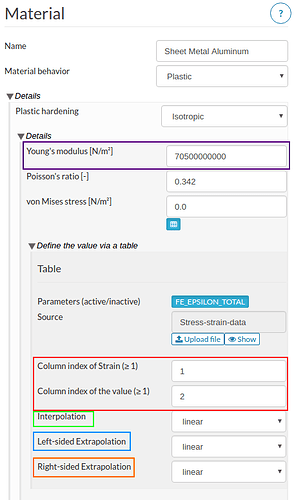

Once the file is uploaded, you will return to material panel with the uploaded file as shown in the figure below.

-

Highlighted in purple is the Young’s modulus value which needs to be calculated by dividing the yield point stress value from strain value e.g. (1.94 e8)/(2.75 e-3) = 70.5 e9 Pa. The wrong calculated value may lead to diverged solution.

-

Highlighted in red are the columns for strain and stress values respectively. This is set to 1 and 2 respectively since our file contain strain and stgress values in first and second column respectively.

-

Highlighted in green is the Interpolation criteria which is set to linear means the data will be interpolated linearly. One can also choose logarithmic if required.

-

Highlighted in blue is the Left-sided Extrapolation criteria which is set to linear. In current case it would mean that any value of stress for strain values below 2.75e-3 linearly interpolated to the first value of 19.4 MPa.

-

Highlighted in orange is the Right-sided Extrapolation criteria which is also set to linear. In current case it would mean that any value of stress for strain values above 1.41 will be increased linearly based on last two values.

That’s it! your elastoplastic material is now defined. You can follow the same procedure to define other elastoplastic material properties such as copper, aluminum etc.

Example project can be seen here.

I was also wondering that this should not be the case. Therefore, I removed it for now. It will be great if you can provide us with the data. Otherwise I will try to find the relevant data somewhere

I was also wondering that this should not be the case. Therefore, I removed it for now. It will be great if you can provide us with the data. Otherwise I will try to find the relevant data somewhere