So I’m interested in modelling compressible (transonic) airflow that is both exterior and interior to a solid which I’m working on (an engine intake). What would be the best way to approach this? I understand the concept of creating a solid to represent the negative space within the intake thereby enabling the airflow through the intake to be modelled - but how do I simultaneously address the airflow around the intake?

HI @ProjectAvenir,

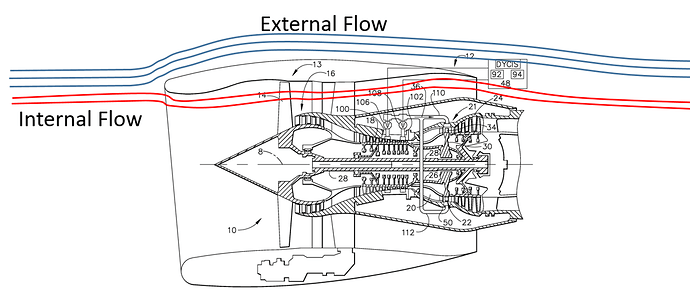

You mentioned engine intake so I am curious if this is what you are talking about?

If this is the case you would model the nacelle, nosecone, and the rest of the structure in your cad system. When you pull it into Simscale you define a the Base Mesh Box which is the overall region for your CFD analysis and then you define a Material Point to tell Simscale to mesh inside or outside the solid.

This Ducted Fan Model is a good example, although its not trans sonic. ![]()

I’ll let the CFD experts answer questions about capabilities.

If I read your question wrong, at least it gave me a good excuse to go look at jet engines. ![]()

Good Luck,

Christopher

Thanks for your assistance. I was able to mesh the geometry sucessfully for a test version of the intake cone. However I have not been able to run the simulation sucessfully. What’s strange is that on the dashboard, I can see a thumbnail rendering of my Intake project - complete with streamlines that look reasonable. Any help you or @Ali_Arafat might be able to offer would be much appreciated!

Regards,

Dan

Another, related, question (sorry!)

When specifying Material for the simulation, there is an option to select one from the Materials Library. For Air there are fields for amount of substance (mol, pre-filled to ‘1’) and molar mass (pre-filled to the standard value). How should I handle this? Since the molar mass, for my purposes, is more or less undefined (freestream air)? Leave it as 1? Use a larger figure, like 3400 (~100kg of air)? Estimate the amount of air flowing through the system during the simulation time? Thanks again!

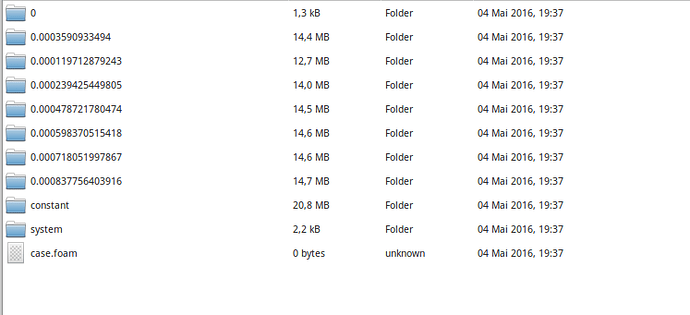

The thumbnail in the dashboard are auto generated. They pickup the latest saved data (write interval) from your simulation runs. In your case the simulation 1 - Run 2 although was incomplete but it did have some saved data as shown below… ( you can view them in the post-processor or download the results to see )

So, the image is generated from that data.

best,

Ali.

The fluid material (Air) properties are irrespective of the quantity of the material. They are the values per mole at standard temperature and pressure.

What you are referring to as " Estimate the amount of air flowing through the system " …is the ‘Mass flow rate’ , which is not a material property. So it is not applicable in material section. So, in short use the default values for Air.

For the simulation setup: see the reference project below and setup the boundary conditions in a similar manner.

You can keep the inlet BC type unchanged and stay with the 'Velocity Inlet ', but follow the outlet as in the sample project. For the side faces you may use symmetry.

For better stability, I would also suggest to make another mesh with slightly bigger surrounding box ( lets say 2times the dimensions).

I hope this helps,

Best,

Ali.

Thanks. It still wasn’t working so I’ve now created a new project (Intake_1) which just models internal flow through the intake volume.

However after 2 runs it is not working either…

Hi @ProjectAvenir,

Are you able to share either your original Project or your simplified Project with the forum so we can loko at it?

Thanks,

Christopher

Hi Christopher and @Ali_Arafat,

Here is the link to my simplified (internal flow) project:

Thanks for your help,

Dan

And the details of the Event Log:

2016-05-07 16:01

Job was prepared successfully.

2016-05-07 16:05

Maximum number of iterations exceeded. More info

So I lowered the Relaxation values (to 1/2 of default) and changed the Tolerances to 0.000001 (absolute) and 0.05 (relative) as suggested. I then got an I/O error on Run 3.

For Run 4 I changed the outlet boundary condition for pressure from ‘Wave Transmissive’ to ‘Set Gradient to Zero.’ This resulted in again getting a ‘Maximum number of iterations exceeded’ error.

I then created a new simulation (Simulation 2), using the Incompressible option, just to see if that would work. For this case I lowered the inlet velocity somewhat (to 210 m/s from 240) and set the outlet pressure to zero.

I’m surprised how much difficulty I’ve had, as the project is quite simple. So I’m sure there is also a simple solution to be found.

Thanks for your help!

Dan

Hi, @ProjectAvenir we are having a detailed look at your project, once its ready we will share the results with you.

Cheers

Thanks - I appreciate it. Note that I’ve added a new mesh, with the outlet extended as per Dr Pawel Sosnowski’s suggestion.

As an example of the final result I’m trying to achieve, it would be something like the Venturi injector flow depicted in:

However I want to model compressible flow in the Mach 0.7-0.9 range. Again, thanks for your help!

Dan

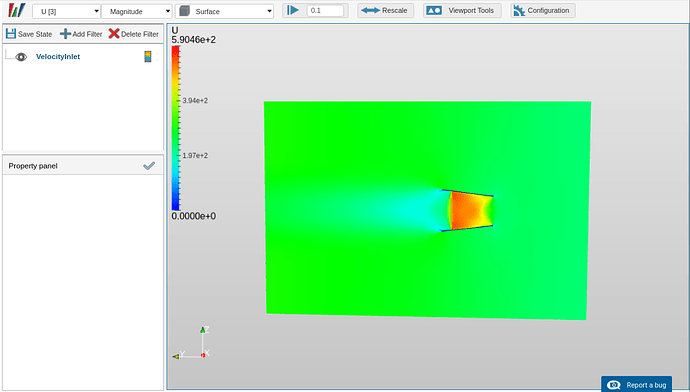

Hi @ProjectAvenir finally we have some results to share with you.

Since transient flow simulations, with high velocity, take too much time to complete so its good practice to save on mesh. We made a symmetric mesh with acceptable mesh size for this simulation. Here is the mesh inside image

For the simulation boundary conditions have to be robust, since compressible flow simulations are very sensitive to boundary conditions. For this simulation we used transonic (0.7 mach) inlet, and wave trasmissive pressure at the outlet, to let shock wave propagate.

Here are some of the results. As you can see even though the inlet is transonic, but when flow hits the inlet of the nozzle, it gets sonic, making the flow supper sonic in the nozzle, as the nozzle is diverging cavity. And at the very end of the nozzle there is shock wave causing the flow velocity to drop to subsonic, which completely agrees with the physics of compressible flows

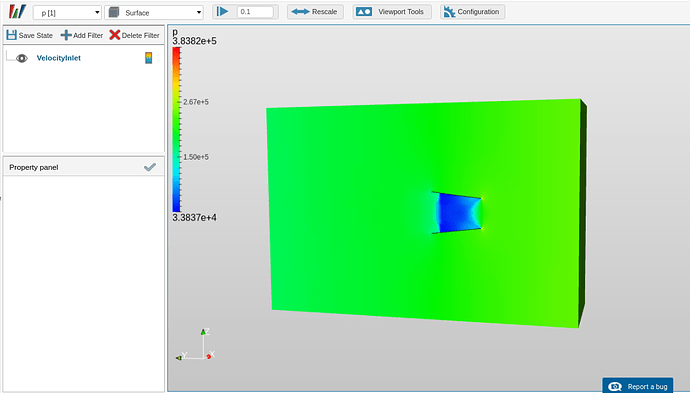

Here is pressure profile in the domain

[Here] is the link to this project. You can change the parameters according to your problem. If you have any further question, feel free to ask. Have a nice day.

Cheers ![]()

Hi AsadAli

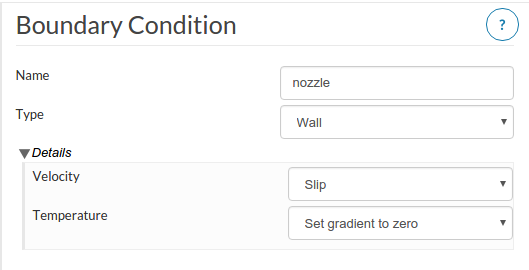

Good work. But I propose one change to your setup - use slip wall on the nozzle:

The laminar code in openfoam solves the full NS equation without any turbulence models - direct numerical simulation. Modelling wall with no-slip means you need a very small wall distance and this can be prohibitively expensive for subsonic flow.

Alternatively, can use symmetry on the wall patch, because symmetry and slip should be the same in math the way I understand it.

I have tried both alternative settings and they both ran.

Thank you all very much for your help. I see what you did by having the bounding box intersect the nozzle. Since I’ll now be redesigning the nozzle based on the results so far, is it correct that all I have to do is define a bounding box with the same relative dimensions, and that will produce the correct mesh?

Also, is there a way to hide the bounding box in the post-processor, or does that require ParaView?

Dan

Hi Dan

If you allow the nozzle and bounding box to intersect, then you will need a symmetry plane. If you dont allow them to intersect and extend the box as far away as it is on the other side, it is then more appropriate for a transient calculation. You may also want to put outlet further downstream when you do mesh independency.

You can right click a surface to hide it from memory.

By the way, if you want to set wall as non-slip in subsonic CFD with a laminar code, then you will need extremely small wall distance to capture the boundary layer and local time stepping for efficient steady state computation. If you use a transient solver in this case, it will take a decade to solve. Consider an inviscid CFD.