Hi all!

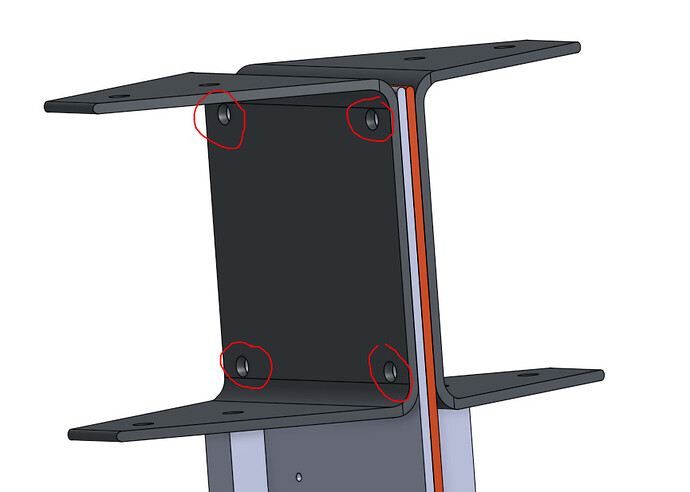

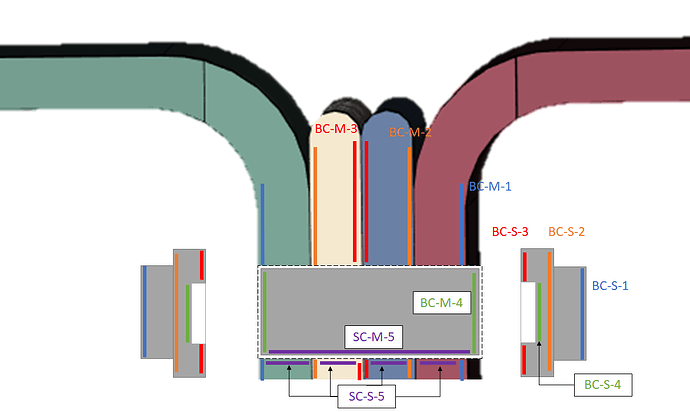

I am carrying out a structural simulation of a multi body structure and I am struggling with the contacts definition. My main problem is that I have several metal components connected to each other by means of bolts, actually, they are 4 parts connected by means of a through hole, as you can see in the figure below.

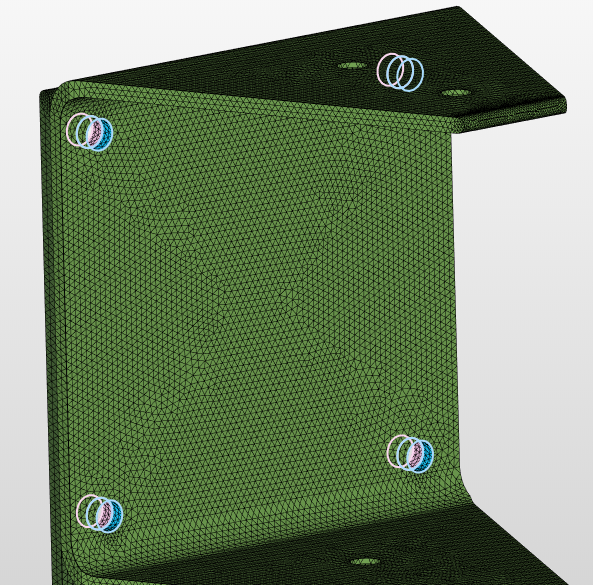

As I am not interested in simulating the bolts and nuts of the structure I am wondering how I might connect all of the parts together. In a previous simulation where I could use symmetry I only had 2 parts and I connected them as shown below.

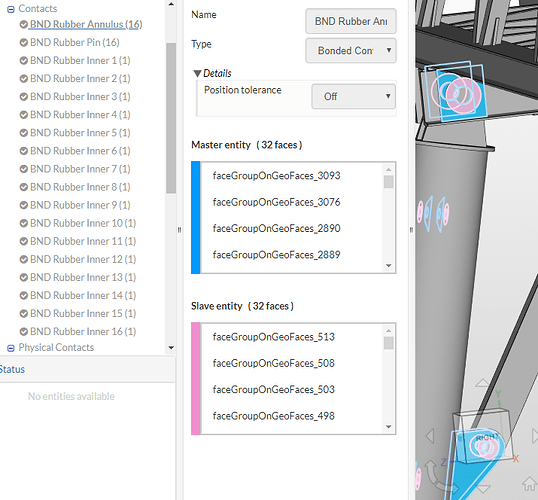

I used the Bonded Contact approach applied in the inner cylindrical faces.

1. Was it an acceptable approach taking into account that both master and slave faces are not strictly in contact, except for the common edge they have in contact?

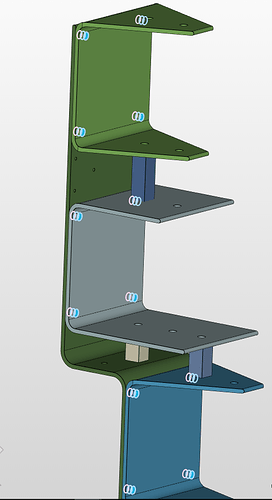

If it was an acceptable approach, my question is:

2. Can I put togheter in a single Bonded Contact constraint the four faces included per each hole shown in the first picture? What aproach would fit into my analysis according to your knowledge?

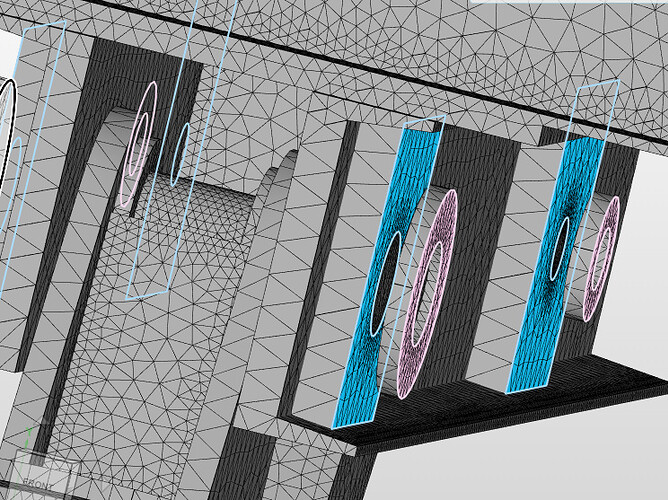

Besides that, I made some tests trying to “shrink” the number of contact constraints during the pre-process stage by doing the following

I “compacted” all the main contacts in only one constraint. However, the results I got are not the same.

3. I guess it is related to the fact that I am using only one constraint over several surfaces belonging to diffferent solids, Am I right? Is there a limitation to use one constraint over only 2 different solids?

I need some help with this issue since it is my first multi solid structural simulation and I am a little lost with it. I have read all the documentation and searched for some topics related to Bonded Contacts, master and slave faces selection but so far I haven’t found “The answer”.

Many thanks in advance.

Regards,

Alex