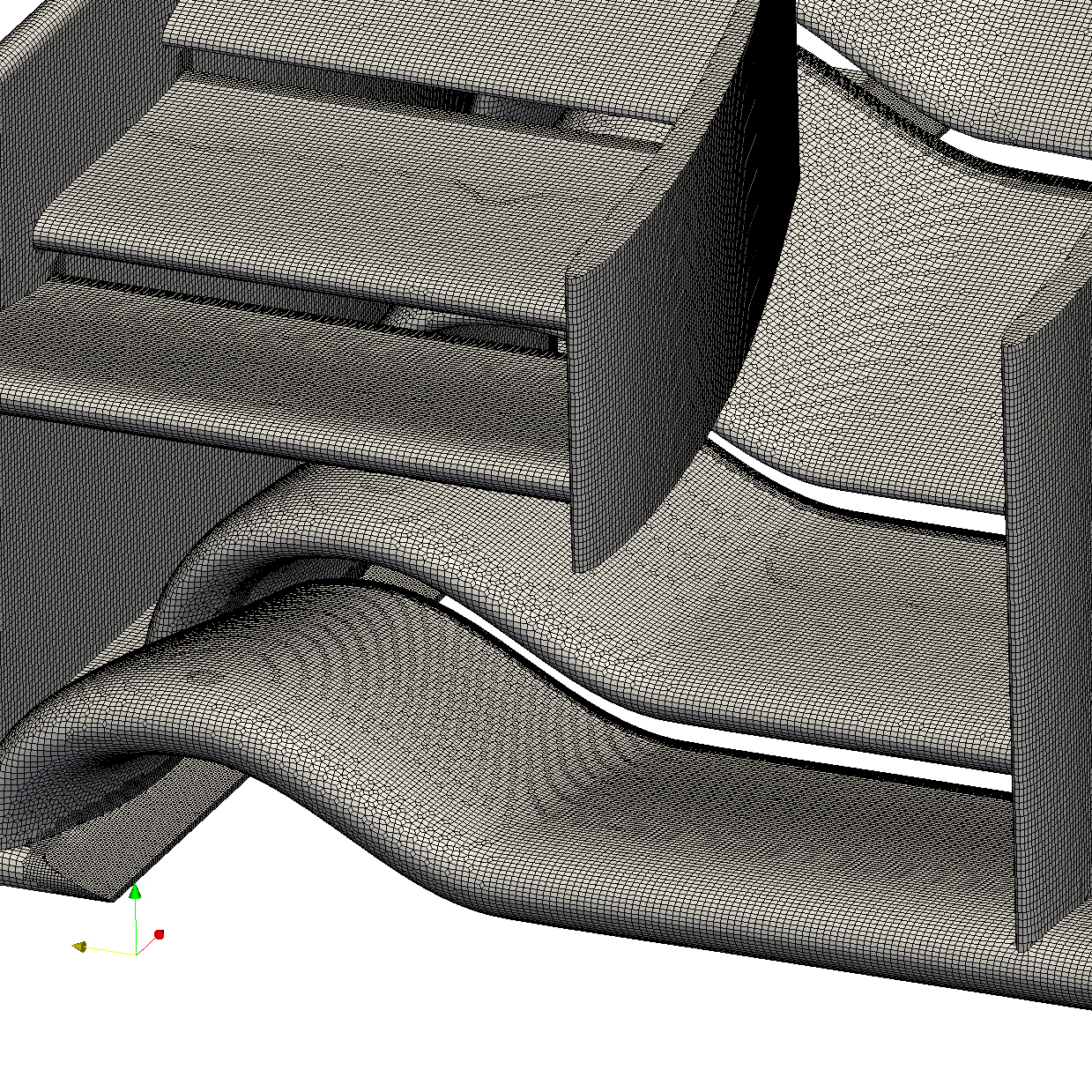

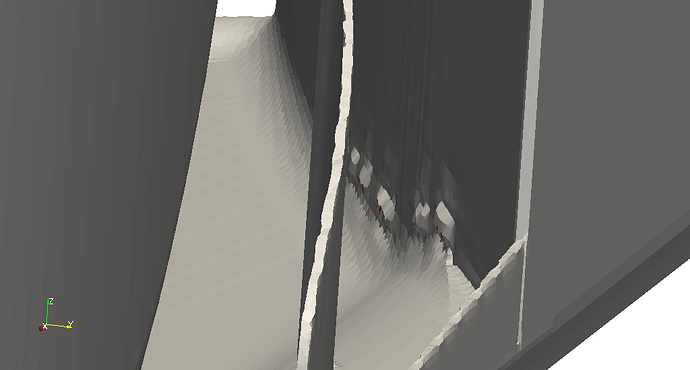

The fine mesh won’t run because it has failed checkMesh:

Checking geometry...

Overall domain bounding box (-11 -0.000530918 -0.0375) (39 11 11)

Mesh (non-empty, non-wedge) directions (1 1 1)

Mesh (non-empty) directions (1 1 1)

Boundary openness (-3.61347e-16 5.91293e-15 -2.25693e-15) OK.

***High aspect ratio cells found, Max aspect ratio: 1.82536e+195, number of cells 10

<<Writing 10 cells with high aspect ratio to set highAspectRatioCells

Minimum face area = 3.95633e-09. Maximum face area = 0.071144. Face area magnitudes OK.

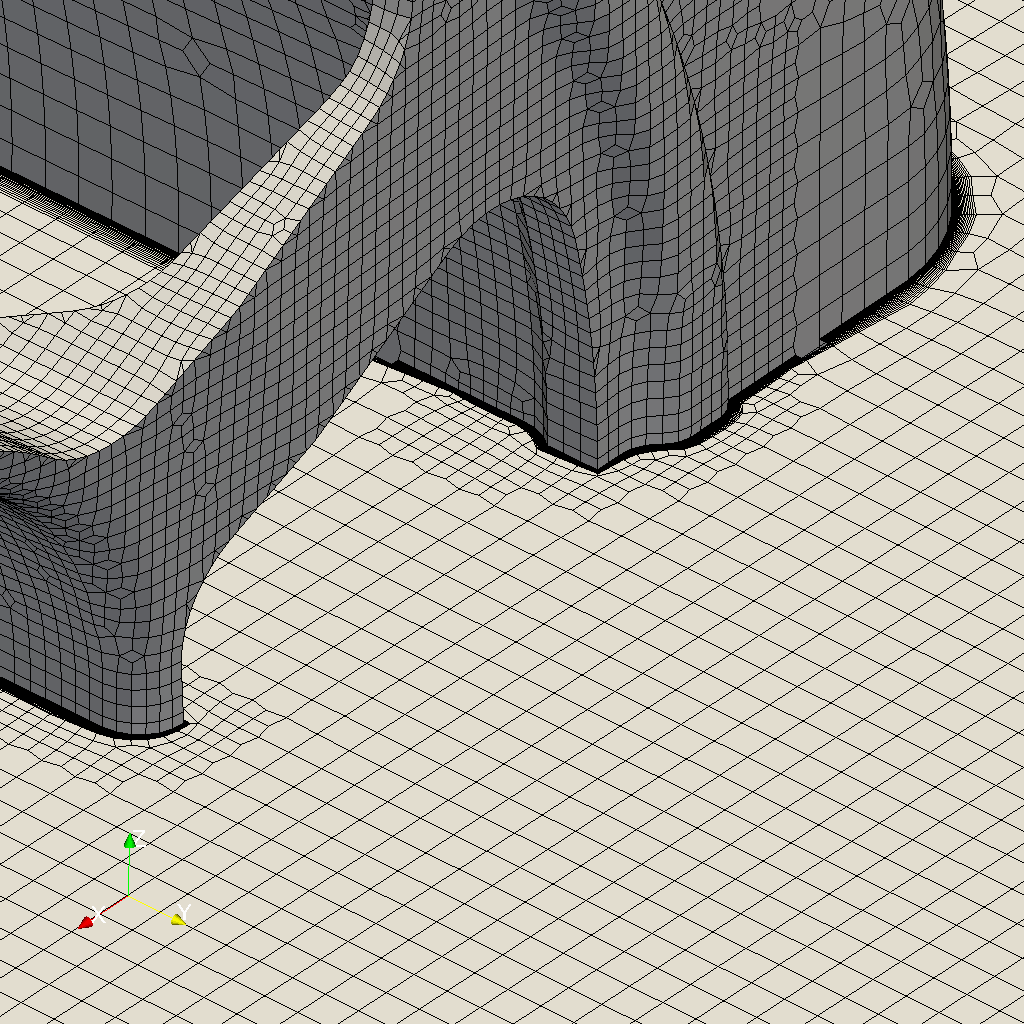

***Zero or negative cell volume detected. Minimum negative volume: -9.07755e-09, Number of negative volume cells: 10

<<Writing 10 zero volume cells to set zeroVolumeCells

Mesh non-orthogonality Max: 175.416 average: 8.48142

*Number of severely non-orthogonal (> 70 degrees) faces: 37.

***Number of non-orthogonality errors: 15.

<<Writing 52 non-orthogonal faces to set nonOrthoFaces

***Error in face pyramids: 74 faces are incorrectly oriented.

<<Writing 66 faces with incorrect orientation to set wrongOrientedFaces

***Max skewness = 104.595, 368 highly skew faces detected which may impair the quality of the results

<<Writing 368 skew faces to set skewFaces

Coupled point location match (average 0) OK.

Failed 5 mesh checks.

The more the stars, the worse the problem. But it is I believe the negative cell volumes that kill the job.

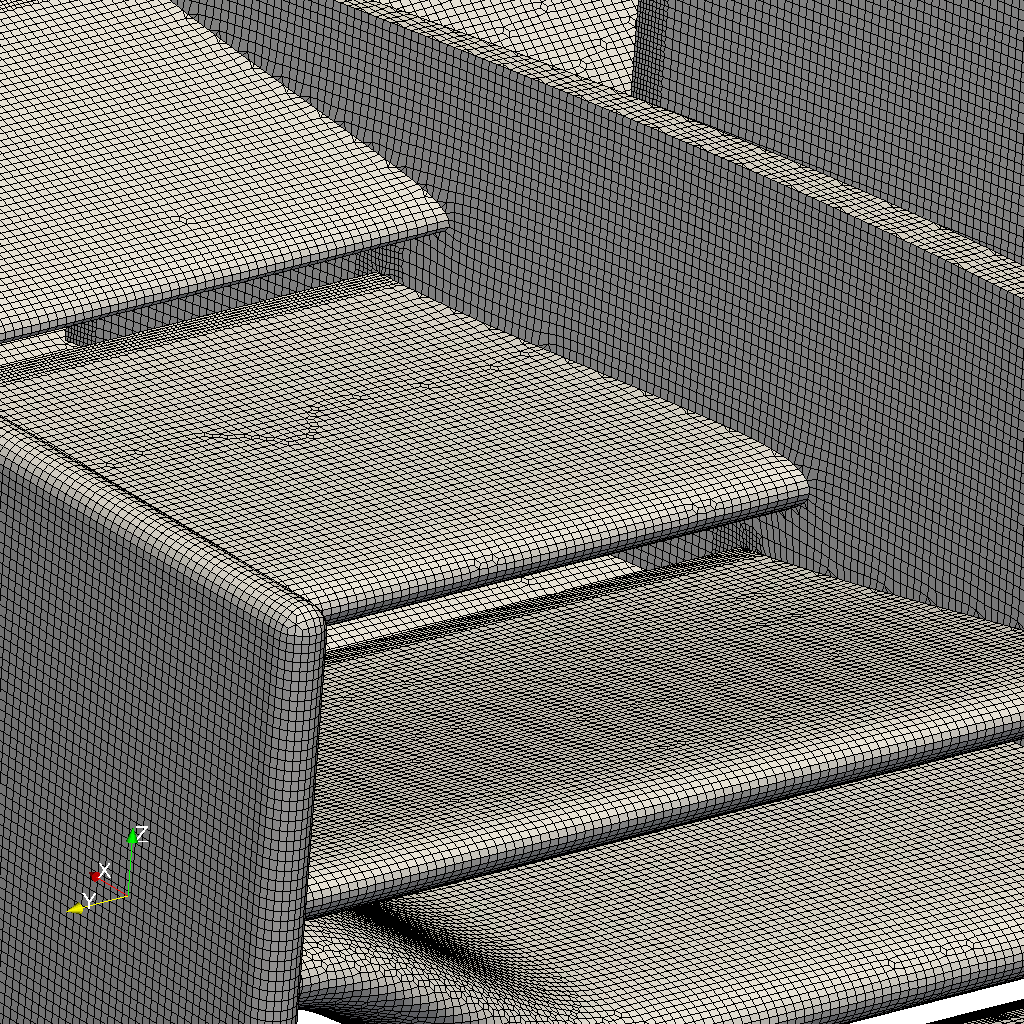

The coarse mesh ran because checkMesh only returned:

Checking geometry...

Overall domain bounding box (-11 -0.000567249 -0.0375) (39 11 11)

Mesh (non-empty, non-wedge) directions (1 1 1)

Mesh (non-empty) directions (1 1 1)

Boundary openness (-6.24213e-17 3.15063e-16 1.35568e-15) OK.

Max cell openness = 4.33442e-16 OK.

Max aspect ratio = 38.3736 OK.

Minimum face area = 1.5103e-07. Maximum face area = 0.273126. Face area magnitudes OK.

Min volume = 6.08063e-09. Max volume = 0.132627. Total volume = 6068.62. Cell volumes OK.

Mesh non-orthogonality Max: 64.977 average: 8.98473

Non-orthogonality check OK.

***Error in face pyramids: 1 faces are incorrectly oriented.

<<Writing 1 faces with incorrect orientation to set wrongOrientedFaces

***Max skewness = 15.2136, 131 highly skew faces detected which may impair the quality of the results

<<Writing 131 skew faces to set skewFaces

Coupled point location match (average 0) OK.

Failed 2 mesh checks.

High skewness may or may not affect convergence/accuracy depending where the cells are located. If they are in regions with low gradients they are fine. There is only one wrongly oriented cell, which may also be located somewhere with low field gradients; maybe that’s why the case converged.