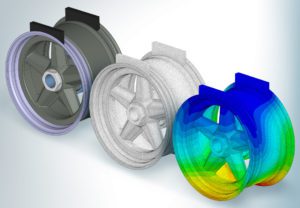

ITW Automotive uses nonlinear static simulation and analysis, now embedded in their engineering design teams at the early stages of product development. In this case study, we demonstrate how ITW Automotive has deployed engineering simulation in the cloud at an enterprise level and, using a specific example of a pipe and anchor clips, how they account for non-linear materials, contacts, and effects to predict large deformations and optimize clip designs. Deploying simulation at an early stage has accelerated time to development and significantly reduced physical testing costs by leveraging the parametric modeling capabilities in SimScale. This also ensures that poor design concepts are disqualified earlier leading to faster overall development times and reduced risk of part failure. The anchor clips in question, have been used in the new Volvo XC90 hybrid vehicle and are a critical component for vehicle safety and performance. Massimo Savi is a mechanical design engineer at ITW Automotive with a focus on plastic fastener component design and development. Simulation is critical during product design as it allows his team to:

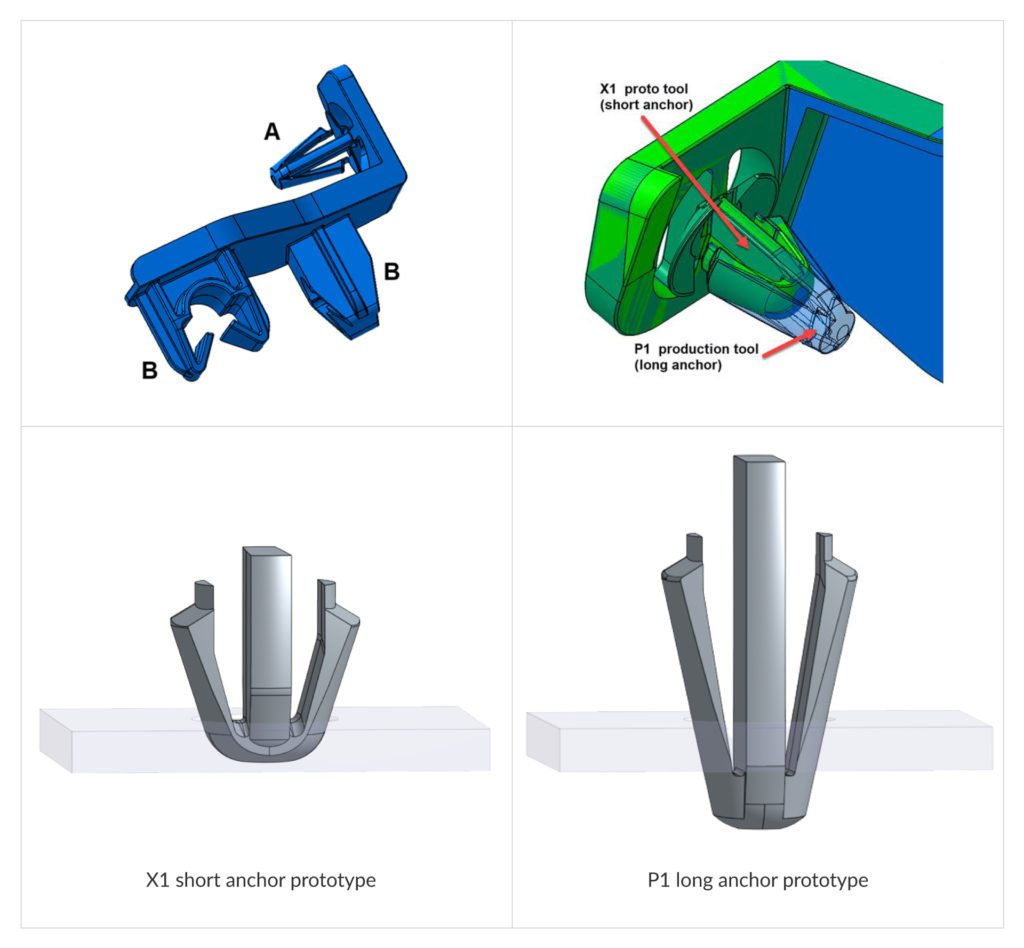

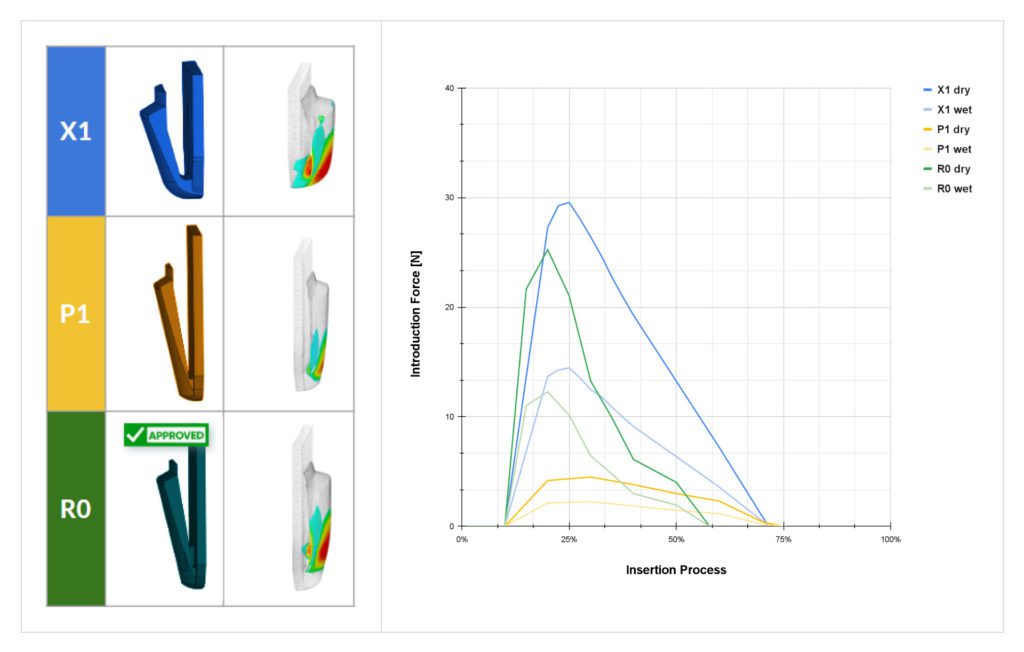

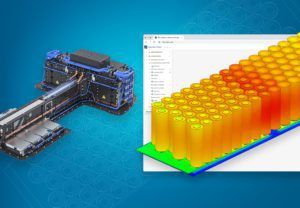

In this example, an automotive engine bay fastener used to connect pipework to metal housing is simulated and optimized. The product includes two types of clips, an anchor clip (A) and two pipe clips (B). Prototype designs are created in a short (X1) and long (P1) anchor configuration. The short X1 prototype failed physical testing requirements due to a high introduction force during insertion. The entry force thus needs to be decreased by 10-20% to enable easy insertion without any damage to the anchor clip itself and to maintain a strong snap. The anchor length was increased by 5 mm in P1 (long anchor).

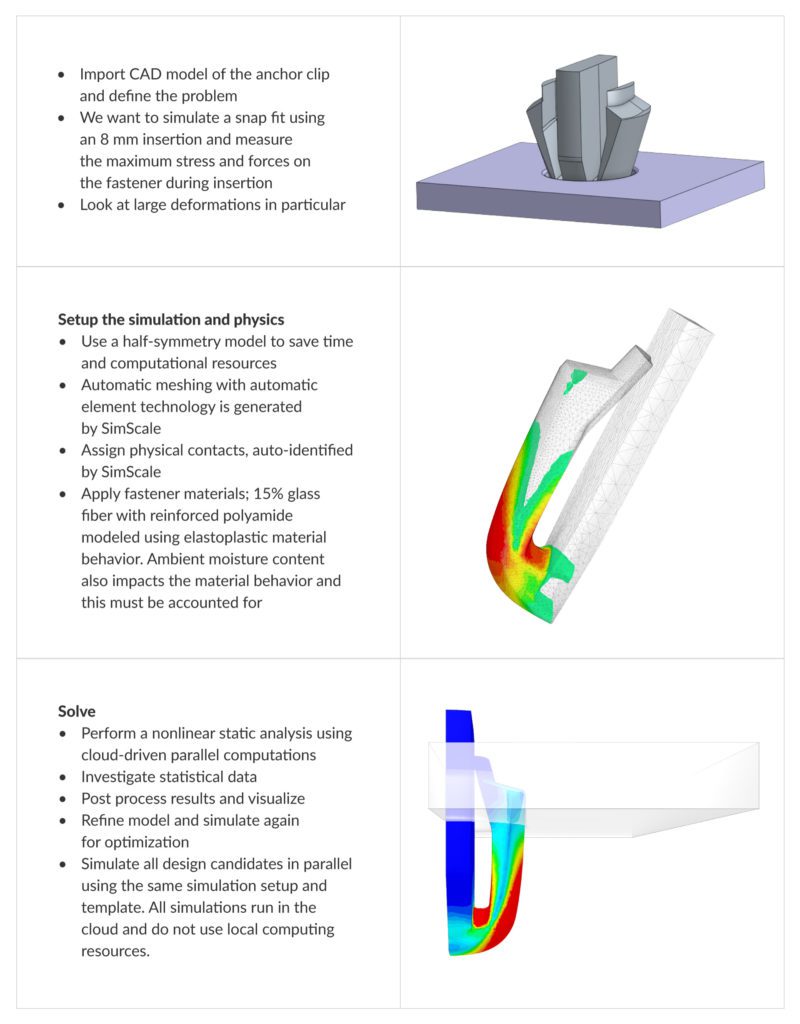

The simulation workflow has the following steps:

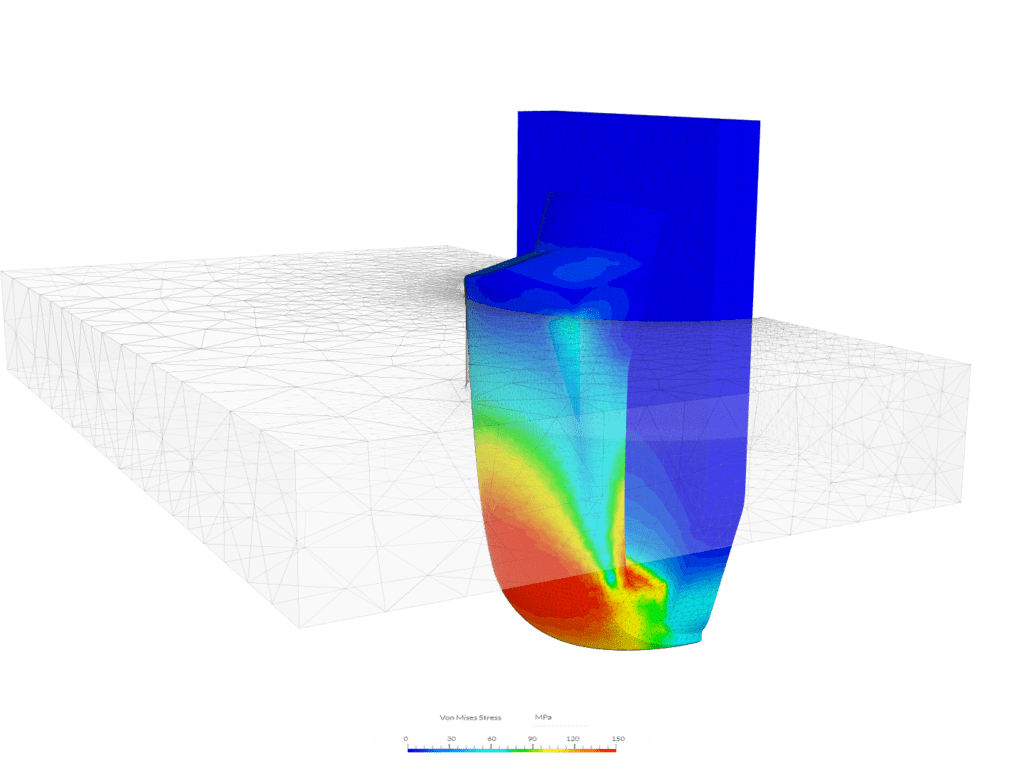

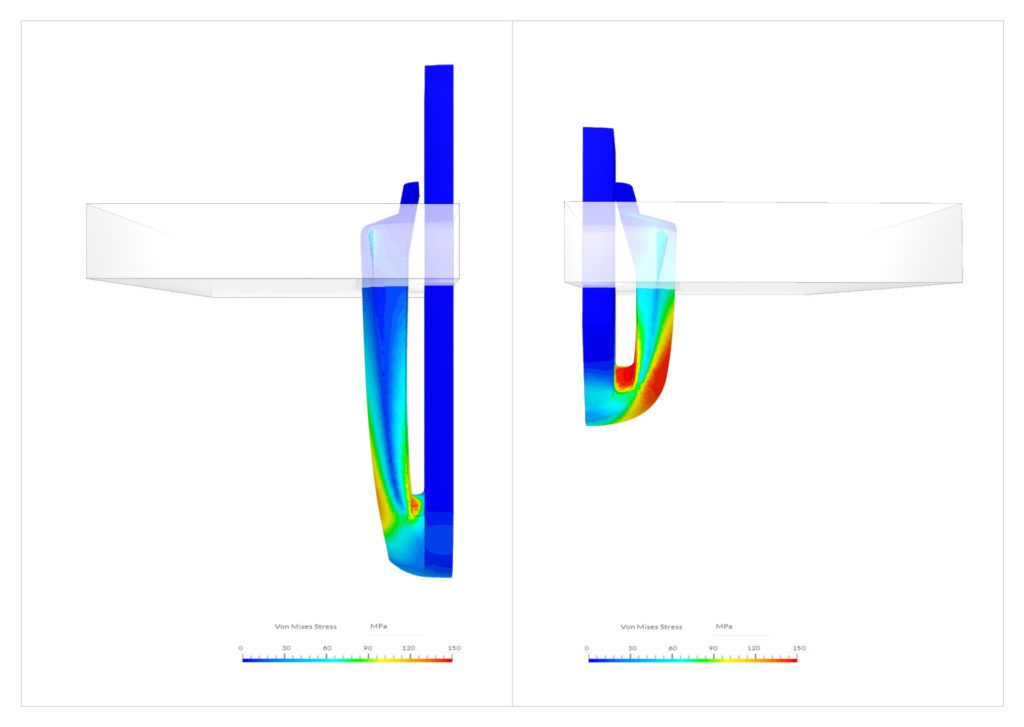

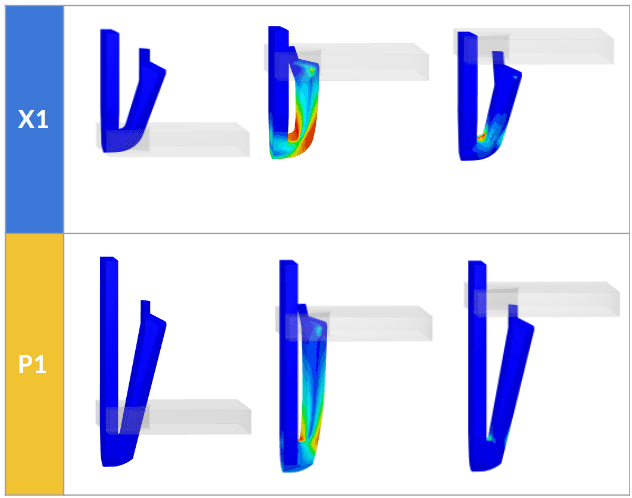

Insights from the first iteration show peak stresses and introduction force during the insertion process (Red denotes high stresses). The long anchor P1 drastically reduced the insertion force by 85% and this was replicated in physical laboratory tests.

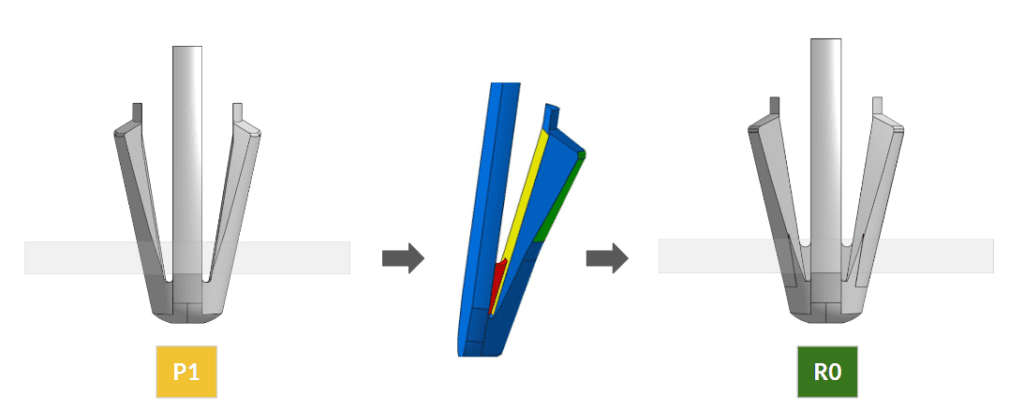

A second design iteration is made to the long anchor clip (P1) resulting in R0. The aim is to further reduce the insertion force to below 30 Newtons by increasing the thickness of the anchor clip by 0.1 mm and adding a central rib (shown in red in the middle image below). The end result (R0) has three modifications over P1 resulting in 25.6 Newtons insertion stress, below the 30 N target. The insertion force has decreased to below the target level whilst maintaining the extraction force needed. Multiple configurations were simulated in parallel using SimScale to arrive at this final solution that was then prototyped for further physical testing. For each design, two different elastoplastic curves were used to model the behavior of the polyamide material reflecting dry and wet conditions that impact material performance. Its material properties are dependent on ambient moisture content that must be accounted for in testing. Simulation and testing must include a wide range of environmental parameters including temperature and humidity.

Just by looking at result visualizations in SimScale, it teaches you a lot and engineers can quickly discern hints on evolving designs. The key advantage of using SimScale for us is to extract fast design insights at the early stages. We can then arrive at a final design faster and have more confidence when moving to the physical prototyping stage.

Massimo Savi

Mechanical Engineer at ITW Automotive

The next step for ITW Automotive is to have every design engineer using SimScale. Coupled with this, the use of 3D printing of small parts is being rapidly adopted and with the capabilities of SimScale, the two have transformed how the design team develops and tests new products. SimScale is used to verify the design performance of small solid parts. The promising design candidates are 3D printed and with further verification using SimScale, ITW can move on to the final prototype variants. Overall, the design team has increased product development times by saving on physical lab testing labor/cost by over 10% per product, which amounts to a significant bottom-line return on investment company-wide.

Watch the related on-demand webinar with ITW to see how they accelerated the development of plastic fastening components.

Sign up for SimScale

and start simulating now