webinar

SimScale Launches Joule Heating Simulation to Accelerate Innovation in Power Electronics

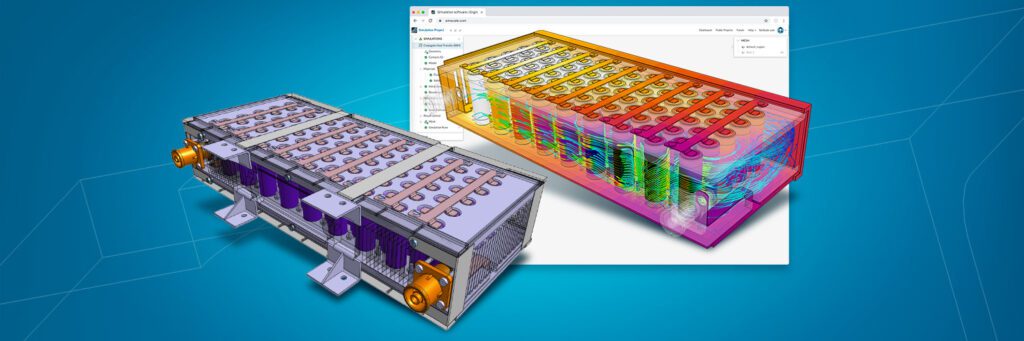

SimScale has introduced new features to conduct Joule heating simulations through a user-friendly interface equipped with robust and automated post-processing capabilities.

Simulating Joule heating is necessary for various industry applications, particularly where resistive heating is a prevalent occurrence. More frequently, the temperature rise resulting from the conversion of electrical energy into thermal energy is an undesired effect that can diminish the overall efficiency of components. Examples include busbars and wiring in power electronics, where efficiency decreases inversely with rising temperatures. A similar impact is observed in batteries, where operating above the ideal temperature range leads to degraded performance and shortened lifespan.

In this webinar, we demonstrated the use of new Joule heating predictions to calculate the electric potential, heat generated, and current density across electronic components. Our experts presented industry-relevant examples of Joule heating simulation applied to various models including battery modules, inverters, fuses, and resistors.

Specifically, an electric vehicle battery model is used. The battery module of a small electric race car uses forced convection air cooling for thermal management and has copper busbars. It has 90 lithium-ion cells in an 18S5P arrangement (18 cells in series, 5 cells in parallel).

Product Manager – Electromagnetics

Nur is part of the product management team at SimScale, holds a master’s degree in computational mechanics, and is currently dedicated to the development and promotion of electromagnetics within SimScale.

“We are really impressed with the SimScale platform. Thanks to the platform’s ease of use, the professional support of SimScale engineers and the perfect communication with them, we were able to efficiently perform simulations and sort out our design problems. It’s hard to imagine how much physical prototyping time and measures we saved thanks to virtual prototyping.”

“When I started with SimScale, I knew from my previous experience how simulations are structured and work, but I had forgotten some details over the years. The great tutorials, documentation, and personal conversations with support have brought me up to date within 2 months of using SimScale. I am now well versed and use SimScale even with smaller problems to confirm my pre-calculations and to quickly compare design studies.”

SimScale is the world’s first cloud-native SaaS engineering simulation platform, giving engineers and designers immediate access to digital prototyping early in the design stage, throughout the entire R&D cycle, and across the entire enterprise. By providing instant access to a single fluid, thermal, and structural simulation tool built on the latest cloud computing technology, SimScale has moved high-fidelity physics simulation technology from a complex and cost-prohibitive desktop application to a user-friendly web application, accessible to any designer and engineer in the world.

Sign up for SimScale

and start simulating now