webinar

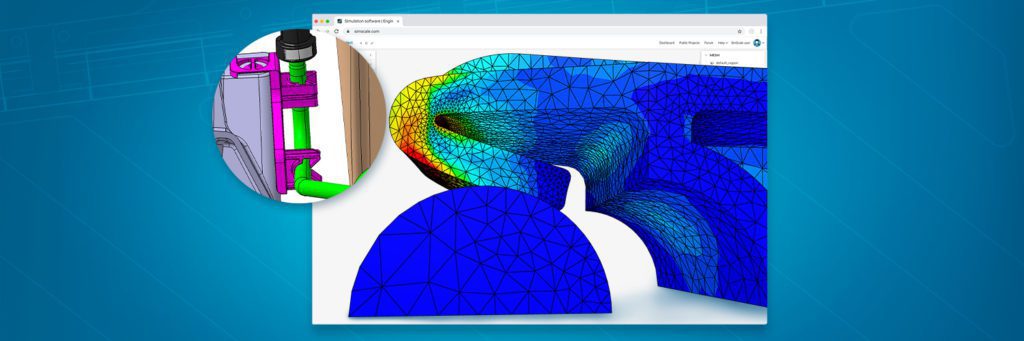

Accelerating the Development of Plastic Fastening Components using Cloud-Native Simulation

Presented in collaboration with:

ITW is a global design and engineering firm serving diverse industry segments from automotive and construction to food products and materials. At the heart of their business model is engineering innovation that requires the right design tools at the right time. ITW Automotive, a leading global supplier of auto parts, uses cloud-native engineering simulation in early stage design of their high-performance plastic fastening components.

ITW showcases the use of non-linear static analysis and how they have embedded simulation in their early-stage design process. The presenters demonstrate a live case study of pipe and anchor clips, and how they account for non-linear materials, contacts, and effects to predict large deformations and optimize the clip design to reduce the risk of part failure. Simulation has accelerated their time to development and significantly reduced physical testing costs by leveraging the parametric modeling capabilities in SimScale. This also ensures that poor design concepts are disqualified earlier leading to faster overall development times.

Product Manager – Structural Mechanics

David is the product manager for Structural Mechanics at SimScale. He brings with him years of professional experience in CAE, with a background in marine engineering. He is committed to helping organizations discover the benefits of early-stage simulation and works to make nonlinear and dynamic FEA applications accessible to design engineers worldwide.

Project Engineer

Massimo is an Industrial designer and engineer with 17 years experience in plastic fasteners and components for ITW, made using injection molding technology.

“We are really impressed with the SimScale platform. Thanks to the platform’s ease of use, the professional support of SimScale engineers and the perfect communication with them, we were able to efficiently perform simulations and sort out our design problems. It’s hard to imagine how much physical prototyping time and measures we saved thanks to virtual prototyping.”

“When I started with SimScale, I knew from my previous experience how simulations are structured and work, but I had forgotten some details over the years. The great tutorials, documentation, and personal conversations with support have brought me up to date within 2 months of using SimScale. I am now well versed and use SimScale even with smaller problems to confirm my pre-calculations and to quickly compare design studies.”

SimScale is the world’s first cloud-native SaaS engineering simulation platform, giving engineers and designers immediate access to digital prototyping early in the design stage, throughout the entire R&D cycle, and across the entire enterprise. By providing instant access to a single fluid, thermal, and structural simulation tool built on the latest cloud computing technology, SimScale has moved high-fidelity physics simulation technology from a complex and cost-prohibitive desktop application to a user-friendly web application, accessible to any designer and engineer in the world.

Sign up for SimScale

and start simulating now