webinar

Designing the Ultimate High-Performance Bike Wheel

Presented in collaboration with:

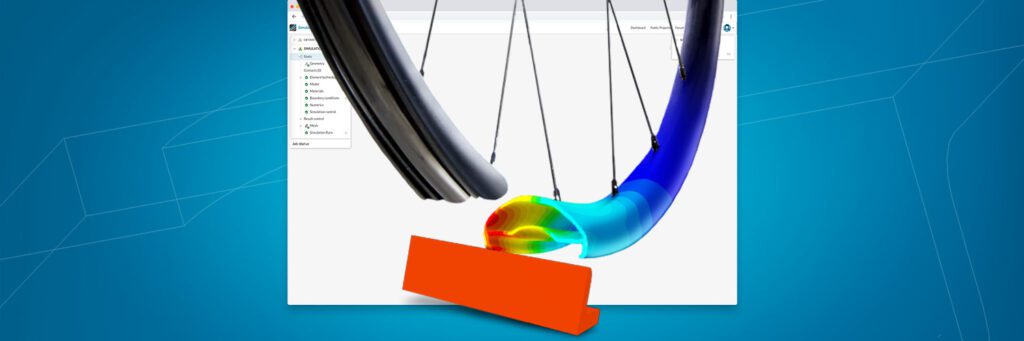

Hunt Bike Wheels creates high-performance wheel and bicycle products for its customers and pushes the limits of wheel aerodynamics, mechanical design, and materials engineering by using the latest engineering simulation features in SimScale.

Hunt uses SimScale to design its Enduro-wide and Trail-wide alloy mountain bike wheels. SimScale FEA analysis allows the company to optimize the design of its wheels for durability and strength and to reduce their weight, in a way that had previously been impossible for Hunt.

The team at Hunt has also used SimScale CFD to create the SUB50 Limitless wheels, the world’s fastest wheels under 50 mm deep. As a result of using SimScale, they have been able to shorten their product development cycle from two years to six months and have saved £30,000 in R&D costs due to less reliance on wind tunnel testing.

Our experts also showcased the latest features in SimScale and how you can get started in a few simple steps.

Design Engineer

Paddy is a Design Engineer at Hunt Bike Wheels, his background is mechanical engineering (M Eng) with his final year studies centring around simulating intake and exhaust air flow. This, conbined with subject matter expertise from having worked in the bike industry for 4 years and competed in national level bike races for over a decade, aids in Hunt’s development of the fastest bicycle wheels on the market.

Solution Engineer

Ioannis is a Solution Engineer at SimScale with 5+ years of engineering simulation experience in a broad range of physics. He is a Mechanical engineer and holds an MSc in Aerospace Engineering, TU Delft.

“ITW is a world leader in plastic components for the automotive industry and we are successfully using SimScale in order to understand the insertion/holding force of our fasteners, and perform vibration and fatigue stress to our brackets and different components. Since I am not a dedicated FEA engineer, I need something fairly intuitive and fast that points me in the right direction and SimScale is perfect for this with a very well-designed interface. I get good results for quite complicated plastic parts that have a lot of deformation. Plus, if I run into trouble, I can always rely on the very helpful and proactive SimScale support team.”

“When I started with SimScale, I knew from my previous experience how simulations are structured and work, but I had forgotten some details over the years. The great tutorials, documentation, and personal conversations with support have brought me up to date within 2 months of using SimScale. I am now well versed and use SimScale even with smaller problems to confirm my pre-calculations and to quickly compare design studies.”

SimScale is the world’s first cloud-native SaaS engineering simulation platform, giving engineers and designers immediate access to digital prototyping early in the design stage, throughout the entire R&D cycle, and across the entire enterprise. By providing instant access to a single fluid, thermal, and structural simulation tool built on the latest cloud computing technology, SimScale has moved high-fidelity physics simulation technology from a complex and cost-prohibitive desktop application to a user-friendly web application, accessible to any designer and engineer in the world.

Sign up for SimScale

and start simulating now