webinar

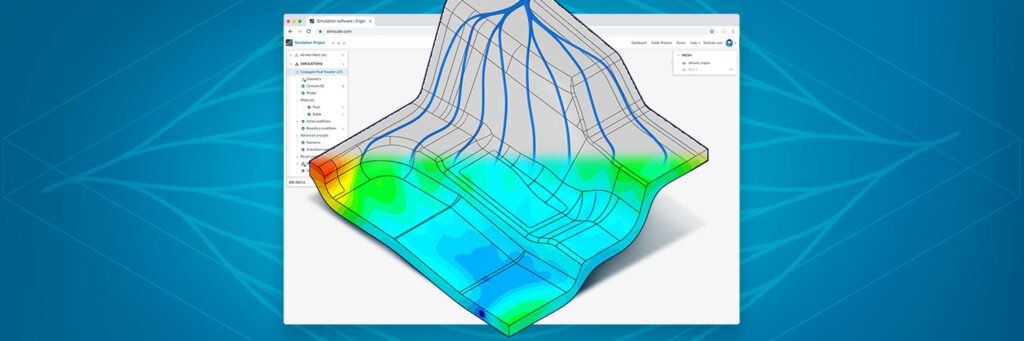

Automated Design of Cooling Channels: Leveraging Cloud-Based CFD with Design Automation Software

Presented in collaboration with:

Watch this 1-hour webinar where we show you how to use connected engineering tools with Computational Fluid Dynamics (CFD) to simulate and analyze your engineering design options using an example of conformal cooling channels that can greatly improve the efficiency of heat exchangers and injection molds.

Synera is an OPEN-connected engineering platform that connects the tools, data, and teams involved in the product development process. SimScale is a cloud-native simulation platform for CFD, FEA, and thermal analysis.

Product Manager and Partnerships Manager

At Synera, Andrew Sartorelli is the Product Manager for Integrations, as well as Software Partnership Lead where helps brings to market solutions for customer pains using internally developed solutions, as well as leveraging partner solutions. He’s spent the past 10 years working for a variety of engineering software companies including Autodesk, nTopology, Hexagon, and now Synera.

Research Scientist/Engineer

Structural engineer by training, develops software solutions and analytical models to improve the workflow for every engineer. Areas of expertise include structural optimisation, complex geometries, and ML.

Application Engineering Manager

Steve is an Application Engineering Manager at SimScale. He has a technical foundation, with a Masters degree in Mechanical Engineering and a Ph.D. in Materials Science. Steve has 7 years of industry-relevant experience from working in aerospace design and engineering simulation.

Application Engineer

Khairi is part of the application engineering team at SimScale with experience in both CFD and FEA. He has a background in Civil engineering and had completed his master studies in computational mechanics from TU Munich.

“ITW is a world leader in plastic components for the automotive industry and we are successfully using SimScale in order to understand the insertion/holding force of our fasteners, and perform vibration and fatigue stress to our brackets and different components. Since I am not a dedicated FEA engineer, I need something fairly intuitive and fast that points me in the right direction and SimScale is perfect for this with a very well-designed interface. I get good results for quite complicated plastic parts that have a lot of deformation. Plus, if I run into trouble, I can always rely on the very helpful and proactive SimScale support team.”

“When I started with SimScale, I knew from my previous experience how simulations are structured and work, but I had forgotten some details over the years. The great tutorials, documentation, and personal conversations with support have brought me up to date within 2 months of using SimScale. I am now well versed and use SimScale even with smaller problems to confirm my pre-calculations and to quickly compare design studies.”

SimScale is the world’s first cloud-native SaaS engineering simulation platform, giving engineers and designers immediate access to digital prototyping early in the design stage, throughout the entire R&D cycle, and across the entire enterprise. By providing instant access to a single fluid, thermal, and structural simulation tool built on the latest cloud computing technology, SimScale has moved high-fidelity physics simulation technology from a complex and cost-prohibitive desktop application to a user-friendly web application, accessible to any designer and engineer in the world.

Sign up for SimScale

and start simulating now