Cloud-based simulation to test, validate, and optimize designs iteratively and easily

Pipes are vital components to machines, systems, and infrastructure across the globe. From domestic plumbing, to agricultural irrigation, to the oil and gas industry, pipes are the connectors between vital resources and customers. With some subsea natural gas pipelines running close to 900 km along the ocean floor, transportation of substances via pipelines needs to be safe and consistent. To ensure reliability and performance, computer-aided engineering is often employed to simulate and test stresses on pipes and associated fixtures and fittings.

The most common use for pipes is for fluid conveyance. However pipes are also used for moving gaseous, solid, and semi-solid substances. Pipes vary in size, shape, and material depending on what they are transporting, the temperatures they need to withstand, and the conditions in which they will operate.

Pipes and pipework are used in industries such as:

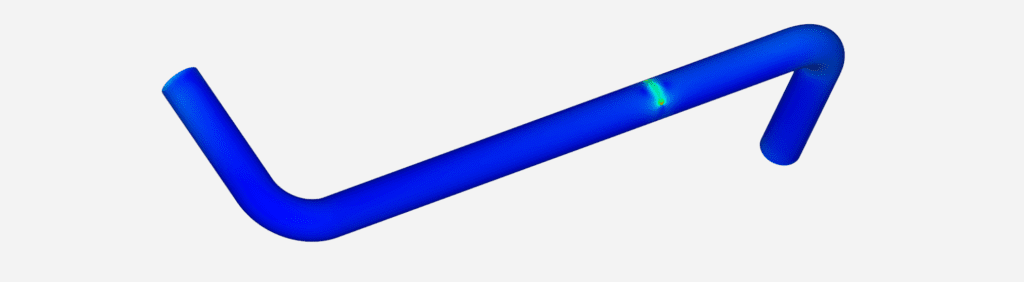

Pipes need to allow flow while withstanding temperature and pressure changes to avoid damage or leakage. With computer-aided engineering, material selection, placement, joints, bonding, and fixtures can all be analyzed to see how they will react to external forces. The various stresses and strains can be simulated to ensure the pipe will adequately serve its purpose.

Thanks to the power of the cloud, SimScale has eliminated the high cost of hardware and steep learning curves required by traditional, on-premises tools. With SimScale, engineers can:

Sign up for SimScale

and start simulating now