Optimize structural designs with changing stiffness using cloud-native FEA simulation.

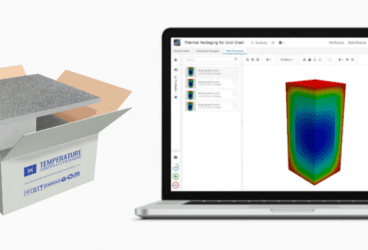

In static structural applications, the stiffness of a structure may change under loading. That’s where nonlinear static analysis comes into play. Using simulation, you can run multiple analyses with incremental loads to account for the change in stiffness, whether it is due to large structural deformation, plastic material behavior, or changes in physical contacts.

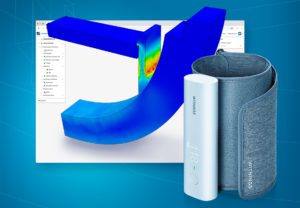

Simulation helps determine your structure’s behavior and kinematics using Finite Element Analysis (FEA), a numerical solution that enables engineers and designers to study structural aspects, such as stress, displacement, and more. Nonlinear analysis is available for static, heat transfer, and thermomechanical analysis types, covering all aspects of a nonlinear relationship between the load and the displacement response.

With SimScale, you can leverage cloud computing to quickly and efficiently analyze your design’s behavior, ultimately speeding up the iterative structural design process as a whole.

Using cloud-native simulation, you can:

Access Hexagon’s Marc™ nonlinear finite element solver through SimScale’s intuitive, cloud-based platform. Engineering teams can now use SimScale to perform advanced nonlinear analysis effortlessly, from manufacturing simulations to failure predictions. Use Marc™ on SimScale to empower innovation, streamline collaboration, and make smarter decisions earlier in the design process.

Elevate your nonlinear structural analysis with SimScale and Hexagon’s Marc™ solver.

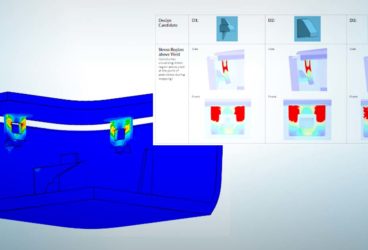

Nonlinear analysis enables users to truly understand and optimize product performance. Whether the problem is a part failure or poor usability, nonlinear analysis helps detect issues early on with simulation, disqualifying poor design concepts upfront and focusing on high-potential ideas that increase productivity.

Using SimScale’s nonlinear analysis tools, you can:

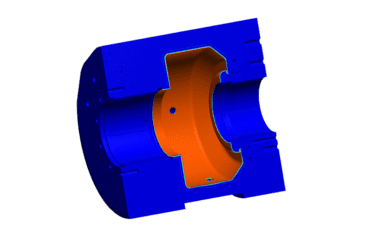

Nonlinear analysis describes the behavior of a structure when the relation between the applied forces and the structure’s displacement response is nonlinear, represented in changing stiffness values.

Using such analysis, you can study the following products:

Nonlinear analysis solutions cover nonlinear contacts, nonlinear materials (elastoplastic and hyperelastic), temperature-dependent properties, thermomechanical interactions, and bolt preload. They enable engineers and designers to make informed design decisions and optimize their product performance early in the design process.

Customer Success

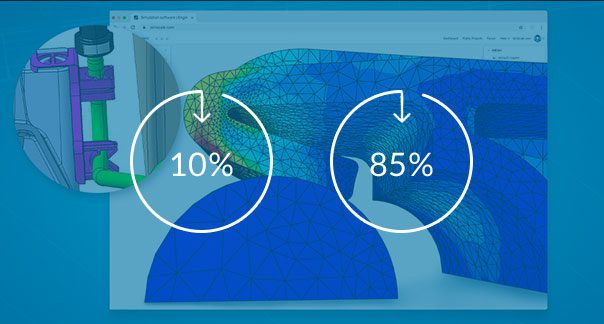

ITW, a global design & engineering firm, uses nonlinear static simulation and analysis to accelerate the development of plastic automotive fastening components. With SimScale, they reduced 10% of their R&D costs and 85% of insertion force.

Check out all the success stories of our customers with structural analysis, including TechSAT, BÖHME, Anybotics, and more.

See All StoriesCheck out the latest nonlinear simulations performed in SimScale and validated against experimental and/or analytical results.

Your hub for everything about nonlinear analyses. Check out our technical documentation section to learn about how to set up a nonlinear analysis simulation.

Sign up for SimScale

and start simulating now