Optimize indoor environment designs for HVAC, data center cooling, and more using cloud-based simulation.

Indoor air quality and thermal comfort are essential to ensuring safe, comfortable, and appropriate conditions. In an indoor environment, airflow is a crucial aspect of design, particularly when implementing mechanical ventilation and cooling/heating systems.

From HVAC to ductwork designs, fume extraction, data center cooling, and cleanroom designs, a well-maintained indoor environment is critical to the functioning of its elements or the comfort of its inhabitants.

Using SimScale’s cloud-based simulation capabilities, including CFD, Heat Transfer, and Thermal Analyses, you can:

SimScale enables fast and accurate analysis of mechanical ventilation systems in the early design process to comply with HVAC regulations, as well as meet the desired performance requirements.

Mechanical ventilation can be employed in a variety of HVAC projects, including residential and commercial buildings:

A ductwork system connects all ventilation system components. So, it requires careful planning to reduce waste and cost and increase the efficiency of the entire system.

SimScale enables engineers to analyze the flow in duct systems – both commercial and residential – early in the design cycle without the high cost of hardware.

Typical types of commercial and industrial ductwork designs are used for:

Fume and smoke extraction systems are critical factors in the safety of occupants within a space. It is essential to test and evaluate the system’s performance safely before implementing it.

SimScale enables early-stage, fast and accurate analysis of fume extraction systems thanks to its cloud-based simulation capabilities.

Fume extraction can be employed in a variety of ways, including but not limited to:

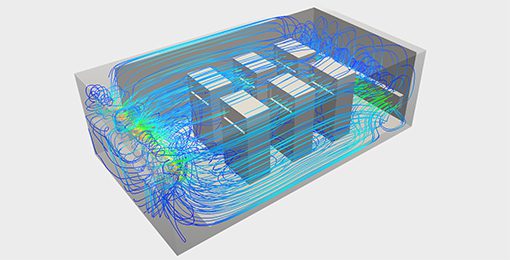

Storing and maintaining large amounts of data requires highly efficient data center infrastructure. Temperature management is at the core of that and is absolutely vital to keeping the equipment running and maintaining its functionality.

Using SimScale’s cloud-based CFD and Thermal Management capabilities, engineers can design their data cooling centers efficiently and early in the design cycle, eliminating hurdles and high costs that come with traditional analysis approaches.

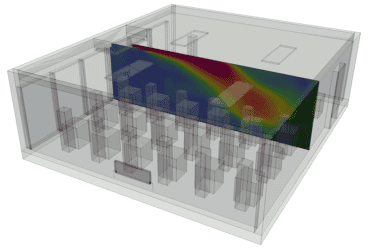

Well-designed cleanroom facilities are necessary for activities performed in a controlled environment with a low level of pollutants, as in manufacturing, pharmaceutical, and scientific research applications.

SimScale empowers engineers to conduct fast and efficient cleanroom design optimizations early in the design process, covering aspects such as:

Controlled freezing and thawing rates are absolutely crucial to maintaining the stability and quality of biotech and biopharma products. Where airflow and heat are concerned, simulation can be extremely useful in assessing and improving HVAC design.

Using SimScale’s cloud-based CFD and Thermal Management capabilities, engineers can optimize the design of freezing and thawing units online and early in the design phase, which helps speed up iterations, run multiple simulations in parallel, and minimize associated costs.

Customer Success

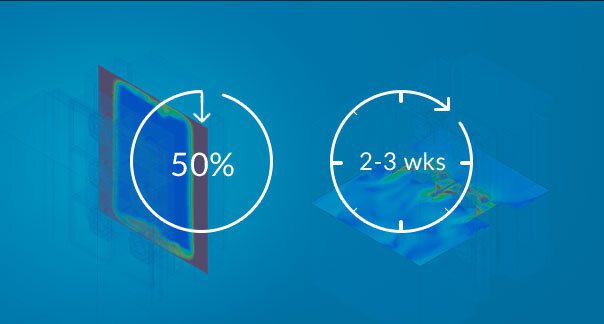

In this analysis, Silent-Aire wanted to develop and test a novel HVAC unit’s mixing performance under various airflow and temperature conditions. Using SimScale, they were able to test and validate their designs before spending money on building prototypes and reduce the number of issues in their first-gen units. They saved about 2-3 weeks of pre-testing and over 40 engineering man-hours.

Check out all the success stories of our customers in the AEC industry, including Paris HVAC, Glanzer Dynamics, and Thermo-Consult.

See All StoriesCheck out the latest urban microclimate simulations performed in SimScale and validated against experimental and/or analytical results.

Your hub for everything about indoor environment analyses. Check out our technical documentation section to learn about how to set up an indoor environment simulation.

Sign up for SimScale

and start simulating now