Cloud-based simulation to test, validate, and optimize designs iteratively and easily

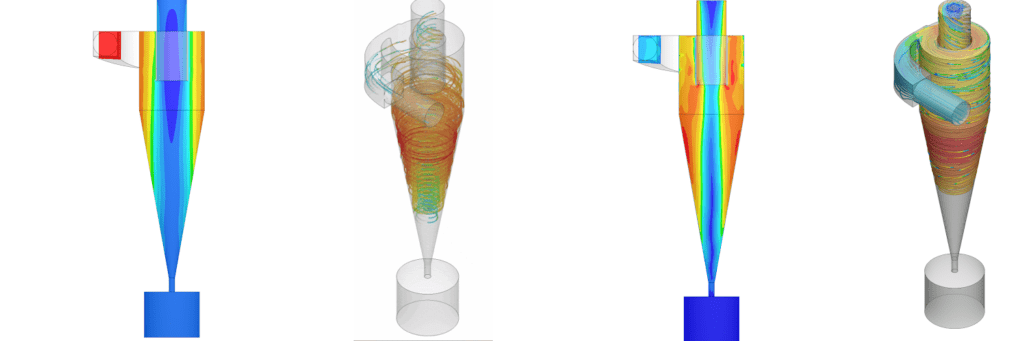

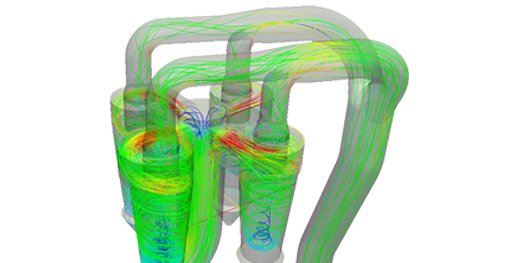

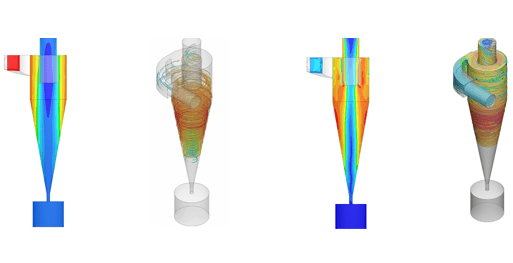

Cyclonic or particle separation is a process used to extract specifically identified particulates from a fluid stream (air, gas or liquid). This cyclone separator design forgoes filters, and instead relies on vortex separation for the operation. These applications vary depending on the fluid from which particles are removed. For example, a hydrocyclone is used for liquid, a gas cyclone for gas, and a dust or air cyclone separator is used for air fluid streams.

Cyclone separators can be applied in a variety of use cases, including but not limited to:

Simulation allows engineers to validate cyclone separator designs before expensive physical prototypes are built. Simulating as early as possible in the design process means more iterations and improvements. However, the high cost of hardware and steep learning curves of traditional, on-premises tools leave many designers to feel that simulation is not an option.

SimScale has eliminated such traditional hurdles, thanks to the power of the cloud. With SimScale, engineers can:

This simulation project slide deck explains how users can analyze pressure drop of a dust cyclone separator depending on the dust concentration, and specifically how to run an incompressible, steady-state airflow simulation.

Sign up for SimScale

and start simulating now