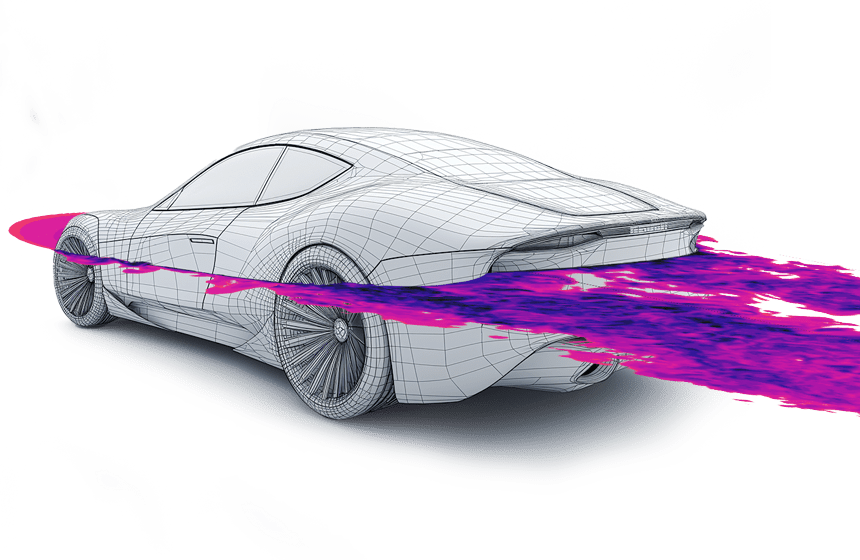

Innovate faster with AI-powered engineering simulation. SimScale enables automotive engineering organizations to simulate earlier and broader, thereby delivering optimized designs faster.

The key to success is reducing the cost and time required to make safe engineering decisions. However, many organizations face challenges with all simulations being exclusively run by experts, leading to time delays, inefficiencies, and limited innovation.

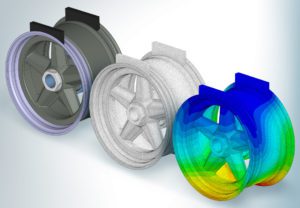

SimScale democratizes simulation by making advanced tools accessible to all engineers, not just simulation experts, flattening the learning curve and reducing coordination delays. This enables faster and more scalable iterations for early-stage design assessments and reduces simulation lead times, leading to earlier, broader simulation in the design process.

With SimScale, organizations can enhance design efficiency, streamline development and innovation, and achieve faster, more effective engineering decisions.

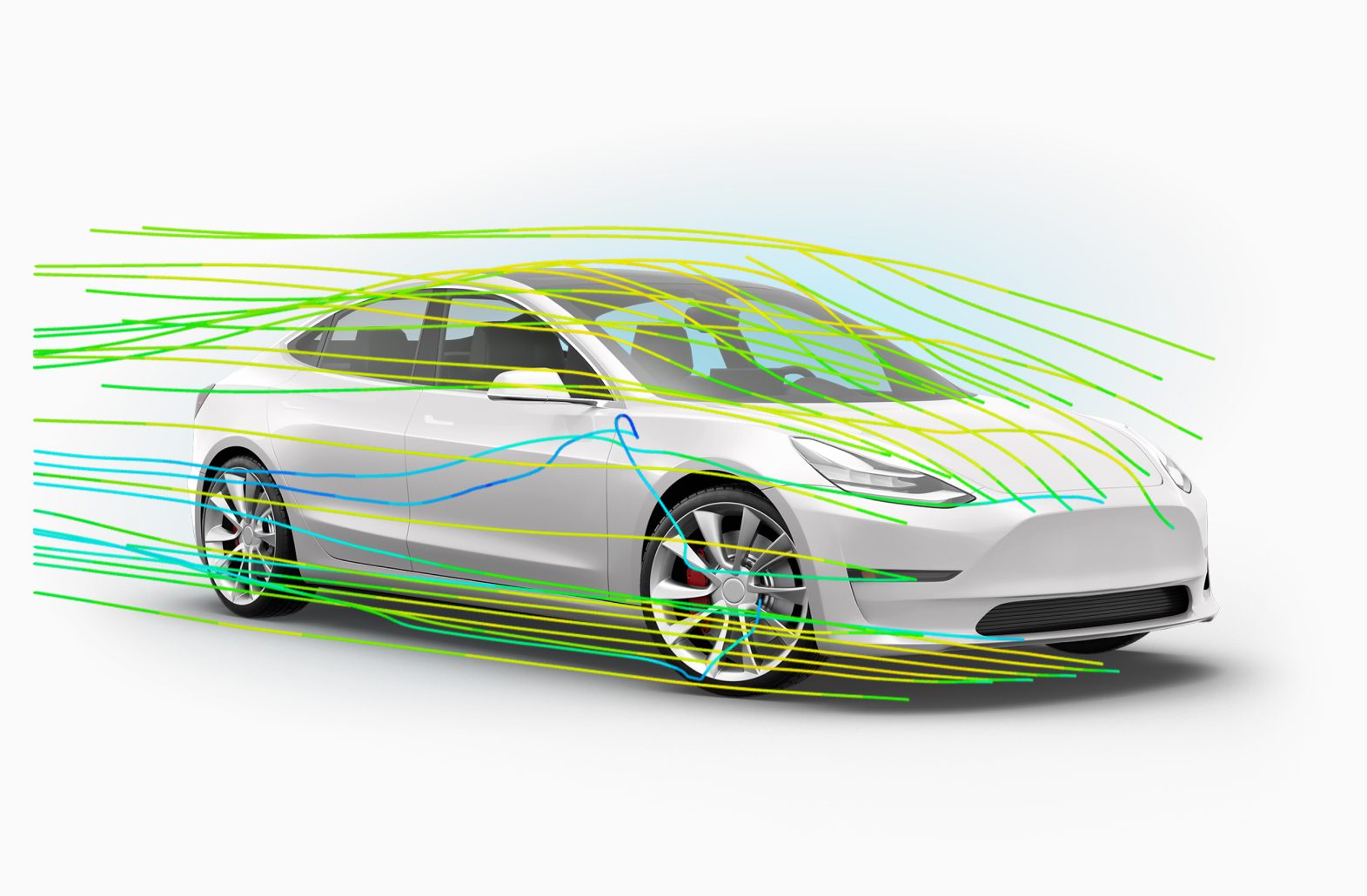

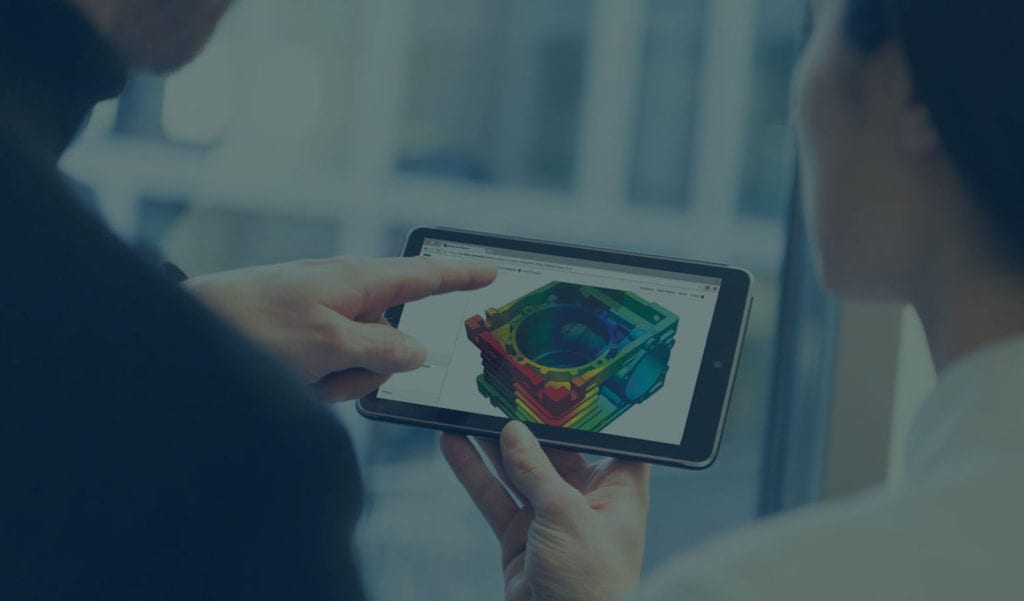

Cloud-native simulation’s HPC elasticity allows unlimited simulation size and simultaneous runs without the need to manage a data center.

More simulations, faster innovation, shorter cycle times.

“With SimScale we don’t have to wait. We can now immediately make a CAD edit and re-run the simulation for quick results.”

Cloud-native simulation allows for decentralized simulation use while maintaining central quality control. Providing everyone with safe and robust access to simulation becomes, for the first time, practically possible.

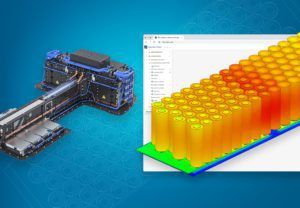

“Using SimScale in the early R&D stages of the product, we were able to fully leverage simulation capabilities into our product design process.”

Next-generation engineering workflows such as generative, optimization, or AI do not work with legacy desktop data silos. Cloud-native simulation persists data in a way immediately accessible for AI, generative, or optimization workflows.

“By using cloud-native CFD in SimScale, the project resulted in savings of 45% compared to using traditional desktop software. This flexibility and cost-saving were the convincing factors for entering into a partnership with SimScale, considering the large scale of customers we serve daily on a global scale.”

Learn more about how you can optimize your automotive design process with SimScale and get industry insights for free.

Customer Success

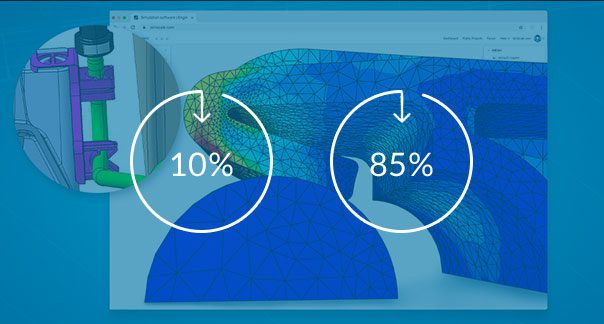

Using SimScale, ITW Automotive simulated the nonlinear static analysis of an anchor clip. With quick iterations and insights, they realized a 10% reduction in R&D costs and 85% reduction in insertion force.

Check out all the success stories of our customers in the automotive and transportation industry.

See All Stories

Sign up for SimScale

and start simulating now