aluminum plate quench of .187 steel

About this project

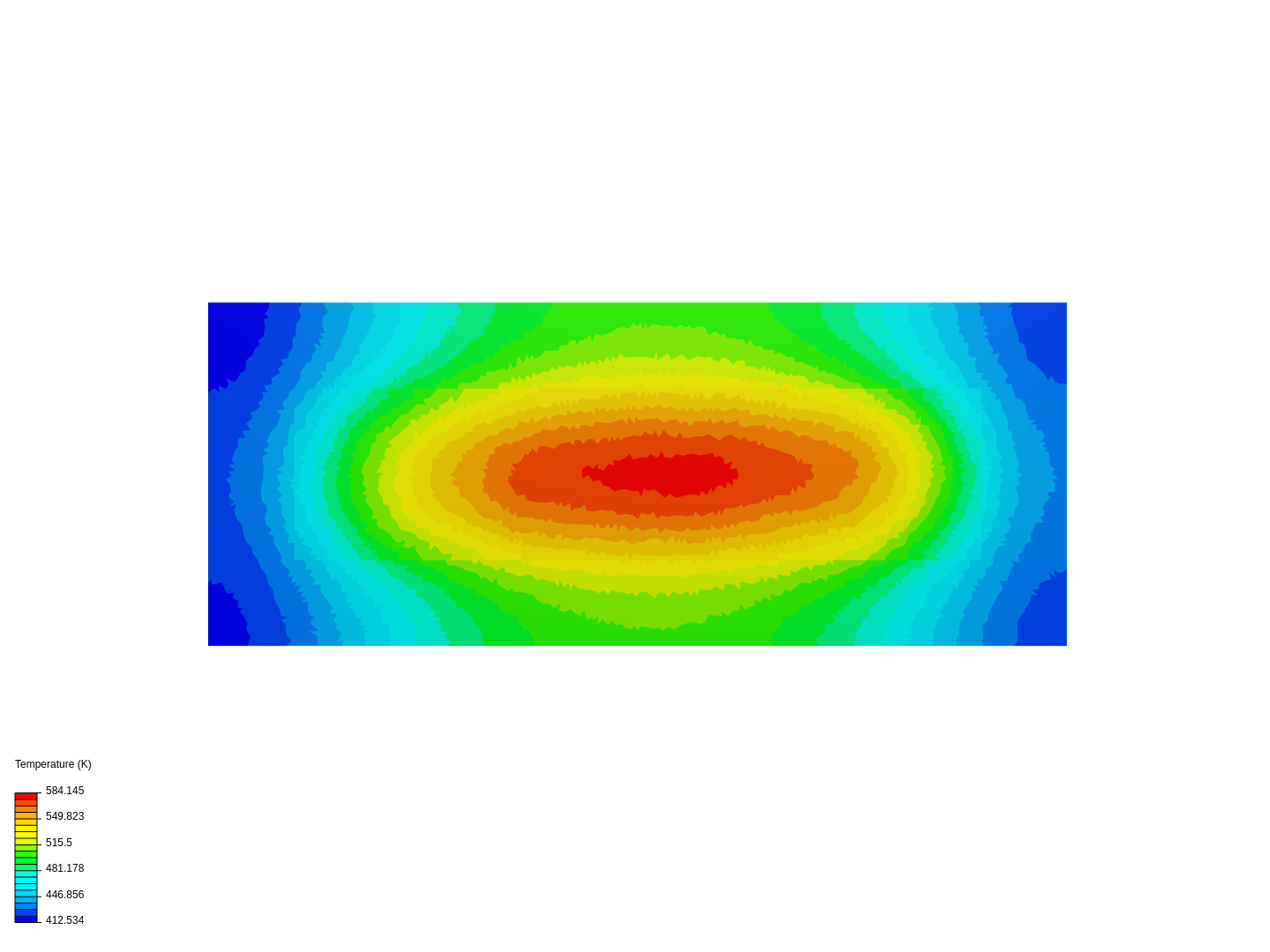

Simulate plate quench of 3/16in 01 tool steel. Note that simulation shows only half of the quench (one plate and .097 steel stock) to better see center line temperature (e.g. when the knife edge would be after grinding bevel). This simulation assumes no bevels are ground in the blade before quenching. Conclusion: Simulation suggests that in ideal conditions 3/16in steel can be quenched from 800 C to 400 C in 7 seconds (at the edges, not in the center) using 1.5in aluminum quench plates. This is fast enough for full edge hardness of most oil hardening tool steels (O1, 97 etc). NOT fast enough to avoid pearlite in the cutting edge in faster steels like 52100 and 8760. Definitely NOT fast enough for water hardening steels (W1, 1095 )

Related Projects

Project History

6d7b7b5fd80046 created this project

6d7b7b5fd80046 copied this project