Hey Jousef!

Thanks for the link. I am looking in to it and will get back to you once I have something

Best,

Ahmed

Hey Jousef!

Thanks for the link. I am looking in to it and will get back to you once I have something

Best,

Ahmed

Hi @jousefm, what is the purpose of this simulation? I’m asking in case there may be a simpler way to achieve the outcome you are looking for.

Regards, Ben

Hey @BenLewis,

thanks for jumping in. Well I just wanted to see if I can generate an animated output with a moving inner ring and a fixed outer ring trying to see the change in stress and strain within the rolling elements over time.

So I was just curious about that

Cheers,

Jousef

Hi @jousefm, I’d like to help you with this one. Give me a couple of days to square away some other tasks and I’ll get back to you.

Hey Ben (@BenLewis)!

Thanks a lot for your interest. That will be great! But currently I am also working on it and good news is that it’s working out for now. All I have to do is to complete a simulation with bit finer mesh. I would say that let me come up with some solution and then you can take it over  So that you don’t have to spend much time over it

So that you don’t have to spend much time over it

Best,

Ahmed

@jousefm @BenLewis Just a quick update. I gave it a try. Below you can see the animation of the outcome with a coarse mesh:

I used frictional penalty contact with friction coefficient of 0.5. Also fictitious clearance of 0.0005 is applied on master surfaces i.e. inner and outer ring internal surfaces. The inner ring in this case is rotated 10 degree.

I am currently running cases with and without fictitious clearance on finer mesh. Once I am done I will forward my project link here ![]()

Best,

Ahmed

Super cool @ahmedhussain18!  Looks almost like in Ansys.Well…I did not expect anything else

Looks almost like in Ansys.Well…I did not expect anything else

Concerning the fictitious clearance: Is this like an artificial distance we generate? And does the solver necessarily needs this fictitious clearance in order to calculate the solution or why is the geometrical “gap” (if we have one) not enough?

Thanks for you efforts Ahmed!

Yes, fictitious clearance is like an artificial clearance. I used it to compress the bearings in order to make it look more realistic and also to attain stability. ![]()

Solver necessarily doesn’t need this. I first ran the simulation without clearance and it also worked, took more time but the results were not quite good due to coarse mesh and little gap between the contact surfaces (specially outer ring one). ![]()

It is not about geometrical gap since I need to compress it rather then creating a gap. So in other words, if you even have a gap between two contacting surfaces, then rather then modifying your geometry you can use fictitious clearance to artificially remove the gap ![]()

My pleasure! stay tuned for the final results ![]()

Best,

Ahmed

Well explained Ahmed, thanks for that.

Cheers buddy!

@jousefm @BenLewis Finally at the end of the day I managed to finish final case with finer mesh. This time it is rotated 45 degree. Below you can see the animation of vonMises stress and displacement magnitude:

You can have a look at the project here: Roller Bearing - SimScale

Best,

Ahmed

Hi @jousefm and @ahmedhussain18,

I have taken a different approach to solve this problem. I wanted to see how the rollers carry a radial load as they move around the race.

To achieve this the rollers don’t actually roll, they are incremented in small steps over time.

You can find a copy of my project here [!!!THIS LINK IS NO LONGER AVAILABLE!!!]

I hope you like it. ![]()

Hi @all,

I have got a similar problem to this which has been giving me a hell of a time. My model is the kind without rings in which I am to find the stress in the cage under a planetary motion (rotational velocity = 11000 rpm).

Hi @oseyemiayobami!

Please share your project with us here in the thread, we will have a look at it as soon as possible.

Best,

Jousef

Hi @oseyemiayobami!

Give me a bit until Ifigured out the issue, getting back to you as soon as possible. Taggind our @fea_squad in the meantime.

Best,

Jousef

okay…

Hi @oseyemiayobami,

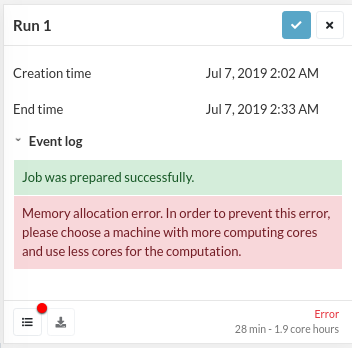

the failure reason is mentioned in the run event log:

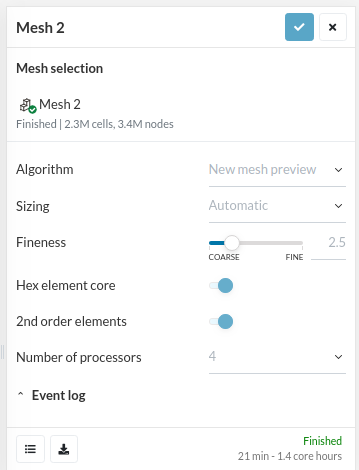

So basically the mesh is too big for the number of cores (and implicitly the RAM attached to them) you selected, it has 3.4 million (!) nodes, and you selected only 4 cores:

With a free account you will likely not be able to solve such large problems, as that is limited to 16-core machines.

Anyways, I would suggest to start with a 1st order mesh and try to solve that one first as this allows to iterate over your trials faster - you might also have some other issues to tackle (e.g. your boundary conditions seem odd).

Best,

Richard