Hi @mmccann!

Unfortunately the Mesh Generator does not fix geometries automatically, this has to be done by the user. Are you able to export your geometry in STL format? You could also try OnShape for that.

Let me know how things go!

Jousef

Hi @mmccann!

Unfortunately the Mesh Generator does not fix geometries automatically, this has to be done by the user. Are you able to export your geometry in STL format? You could also try OnShape for that.

Let me know how things go!

Jousef

I believe I have cleaned the geometry up enough to work with an automesh, I also reduced the car to a half car model.

Do you have any tips for creating your own mesh?

Thank you!

Hi @mmccann!

Is the link the same or did you create another project for the new model? Just to be sure!

Best,

Jousef

I have added the geometry to the same project, however now I am getting a different error. The mesh will finish, but the simulation will run and then error out. However, the error log says that the job was completed successfully. Have you seen this error before?

Hi @mmccann!

The error probably emerges from the very small bounding box domain you have chosen. Make sure you increase its size! Having a look at some Public Projects and using them as a template can help you here! I am pretty sure once you fix the domain size you will have no problems with the simulation!

Best,

Jousef

Good afternoon @jousefm,

I am assuming that you are talking about the background mesh box that is too small?

What would a good size be for it? (Or a general recommendation?)

I have been using some of this tutorial to help me!

Hi @mmccann!

Exactly! For more detailed information on the bounding box size I am tagging @pfernandez here who has a good amount of knowledge on this. For your application I think 2 lengths upstream, 3-4 lengths downstream and 2-3 times the width in each direction are sufficient.

Cheers!

Jousef

Thank you very much!

I have made a second project file, and seem to have gotten decent results using the automesh feature. The link is below.

Do either of you have any good post processing tips?

Hi @mmccann!

I am wondering what you mean by decent results as the last operation you have started is still with a domain that is way too small ![]() Am I missing something here?

Am I missing something here?

And before putting to much text about post-processing itself, let me just give you one of many workshops we had related to post-processing procedures with our platform as well as the offline version of Paraview: FSAE 2017. Of course you can find several others in the Workshop & Webinars Section of the forum. Hope that helps!

Cheers!

Jousef

@jousefm, any results are decent to me right now, because I have not been able to have much success in getting a simulation to finish!

What is the benefit of Paraview VS the online post processor?

Have a great day,

Morgan McCann

Great @mmccann!

Feel free to add some nice comments to your project like it has been done here: Project Template.

With the online post-processor you can immediately see your results and make fast adaptions to the simulation parameters if necessary without having to download all of the data written during the simulation to your local machine. On the other hand the offline version offers more customizability and post-processing features in general.

Hope that short outline helps a bit for future simulations here on SimScale ![]()

All the best!

Jousef

Hey @jousefm,

I have ran into a strange issue with my mesh. The mesh completed successfully, however when I go to select it for a simulation it will not let me. How can I fix this?

I get an error message saying “Your changes could not be saved. Please try with different settings or input.

Error code cmqen4iu”

Project: R5+ and No Aero

Geometry: R5 Added Side Skirts

Mesh: R5_SideSkrits_Morgans_Mesh

Thanks!

Sorry for the multiple posts, but when I tried to remake the mesh, it allowed me to select the mesh. However, the simulation failed. I googled the error and the posts I found online about it are telling me the machine is running out of memory. Is there a way to increase the memory available to the machine?

Thanks!

Hi @mmccann!

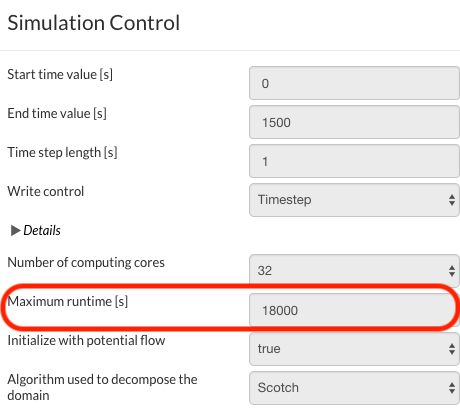

The only simulation I found with a message was one saying: “The specified maximum runtime of the job was exceeded…”. In order to fix this you have to increase the Maximum Runtime in the Simulation Control as depicted in the picture below.

Above the marked field you can define the number of cores. Another issue I found: Your fluid domain is way too small in order to get accurate results for your simulation. Please make sure to increase its size!

All the best!

Jousef

Hello @jousefm, The error I was getting is: “mpirun noticed that process rank 11 with PID 162 on node exited on signal 15 (Terminated).”

That was for the simulation “R5_ChangedInterval” under the project “R5+ and NoAero.”

You will notice that I also expended the size of domain in the mesh.

Thanks for your help!

Hi @mmccann!

There seems to be a big issue with your mesh in the first place with almost 80000 illegal cells which is way too much. On top of that the refinements are too high causing the mesh to load for ages. You can easily go down from 23 million to 10 million cells maybe or even less - at the moment it is just an overkill.

I would fix that first, bring down the number of illegal cells and there should be nothing else in the way to get nice results. Let me know if you have any further question.

Best,

Jousef

How do I lower the illegal cell count?

Decrease the number of cells in each direction?

This mesh is the mesh that the FSAE tutorial showed us how to make.

I really appreciate you helping me out with this! I’m new to CFD and there is a lot to learn. Thank you!

Hi @mmccann!

No worries! First of all make sure that your geometry is watertight as well as avoid overlapping surfaces! I can see some overlap in the front of your car for instance. Decreasing the number of cells was just mentioned as you have way too much cells at the moment (as you noticed it takes very long to load the mesh) - so lowering the refinement levels can definitely help!

Best,

Jousef

Where are you seeing that? In the front wing?

What is a good cell count in each direction?

Hi @mmccann!

Attached a picture that shows an example of overlapping surfaces.

For the number of cells no general statement can be made - that differs from case to case and is not the same approach as in FEM.

In general you perform the simulation on different meshes and look how the solution behaves. You can say that the grid is fine enough, when the difference to the result of a simulation of a finer grid is less than your margin of error.

Other influencing parameters:

The resolution of the boundary layer

Resolution of a free surface

Transition from a dense grid to a coarse grid should be smooth

Hope that helps Morgan! Cheers!

Jousef