Description:

Overview

Snap fit joints are one of the simplest ways to join two bodies together. They can be designed to undergo many assembly-disassembly cycles without any adverse effects to the body. They are easy to manufacture, and come in a wide variety of shapes and sizes. The one common design aspect that all snap fit assemblies have is the presence of a protruding part which deflects briefly upon the introduction of the incoming mating part, and which then snaps back into place.

Input Data

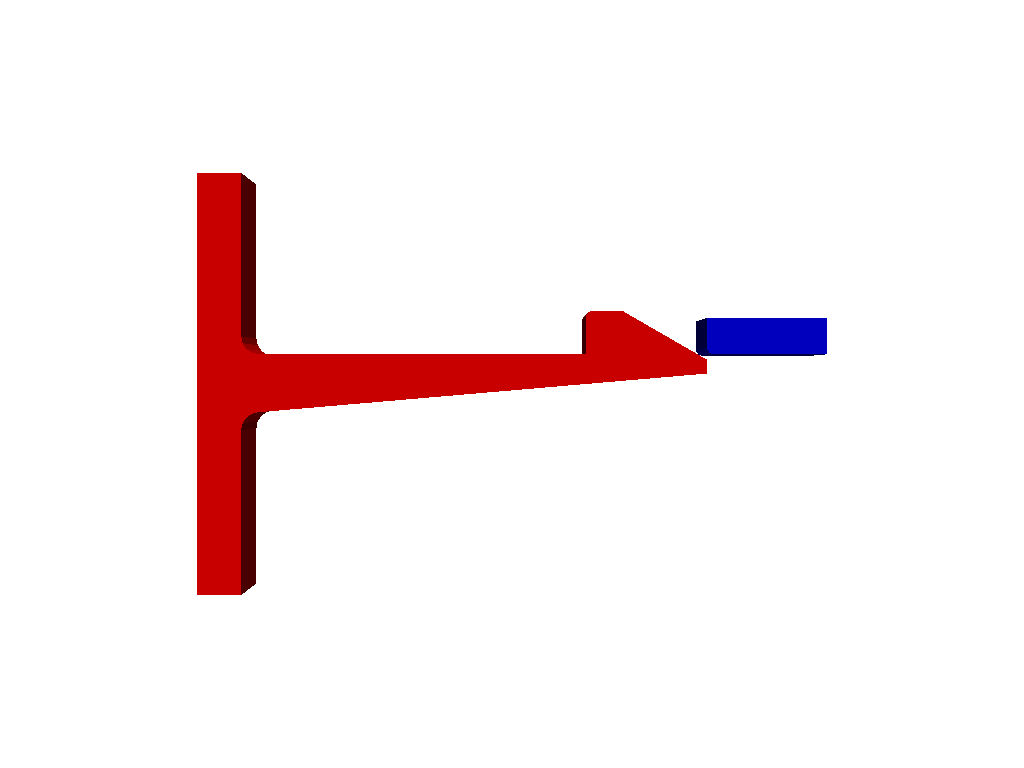

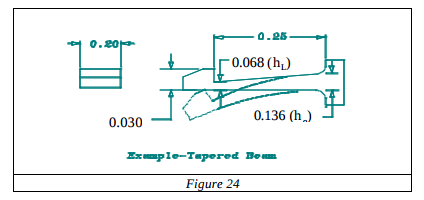

The model can be created using the geometry dimensions provided on page 16 (Fig: 24) in [1]:

Geometry description from [1]; for more details, please refer to the paper.

Purpose

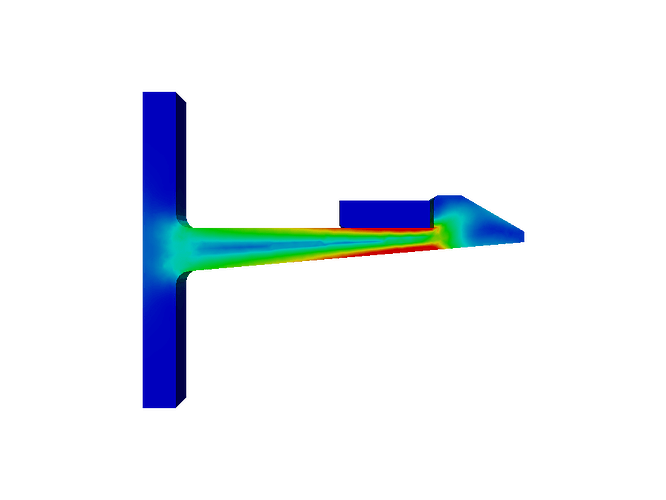

The purpose of this study is to validate the solver for snap-fit simulations by comparing it to the experimental data presented in the paper. The mating force and the maximum deflection of the snap seen in the simulation has to match the experimental values given in the paper.

Key Words

Finite Element Methods (FEM), Finite Element Analysis (FEA), Snap fit, Snap mechanism

Literature & Sources

[1] Tim Spahr. SNAP-FITS FOR ASSEMBLY AND DISASSEMBLY; November 1991

[2] BAYER Material Science, Snap Fit Joints for Plastics

[3] James Low; 3D Hub; How to design snap-fit joints for 3D Printing

Status

Finished by @ojagtap January 20th, 2018.