Hey Welcome to the forum!

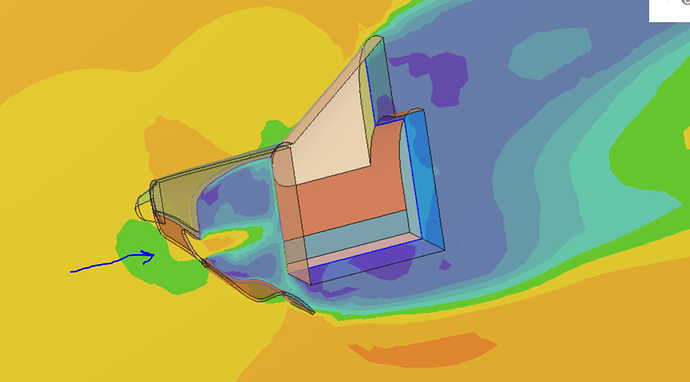

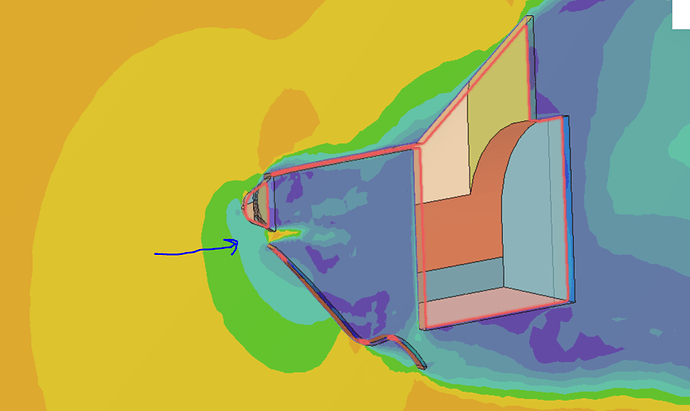

Taking some cutting planes of your geometry it does seem like there is flow entering the two opeinings in the front of the cowl. I assume you were expecting to see flow through the cowl by entering in the front and exiting the rear

X cutting plate at -0.12

X cutting plane at -0.03

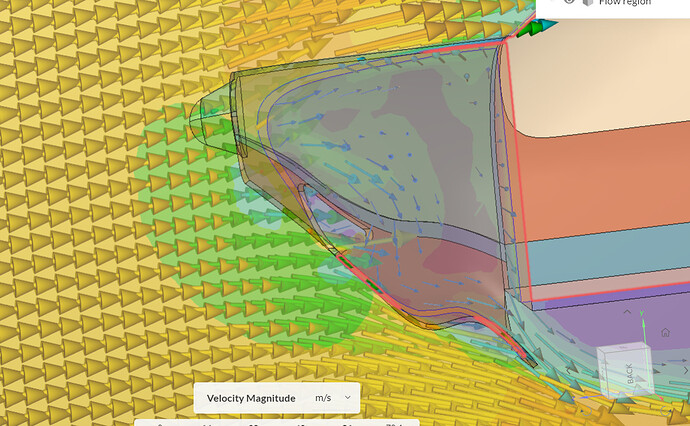

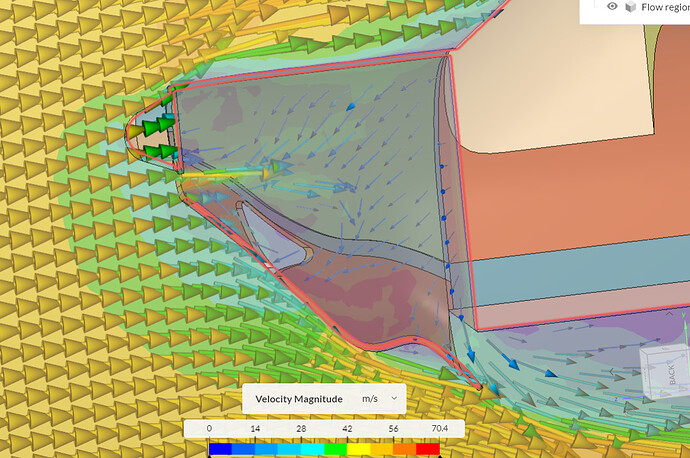

Another useful feature is applying vectors to a cutting plane to get a sense of flow direction. So it does seem like there is flow moving through the openings.

X cutting plate at -0.12

X cutting plane at -0.03 This shows quite a bit of recirculatory flow, possibly effecting how well it exits through the rear

I would also recommend increaseing your bounding box size (enclosure size) as having one too small can effect results. Normally 10x the geometry size is good. So maybe 30m long and 5m tall/wide.

Just post again with any other questions or results

Dan