Documentation

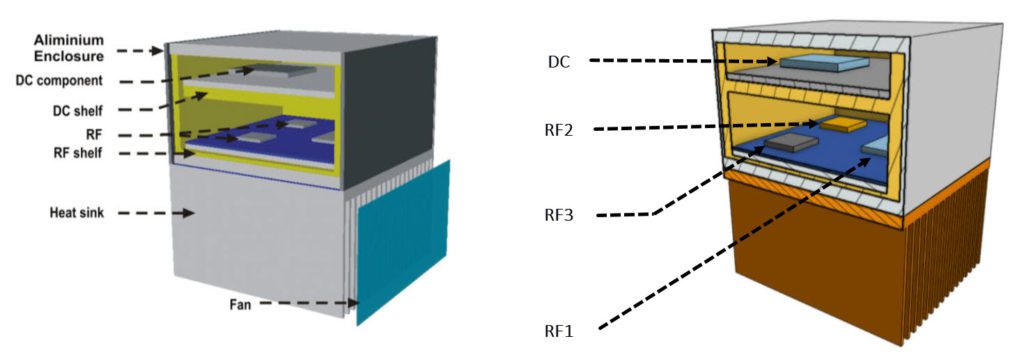

This study aims at validating the CHT v2 and CHT (IBM) solvers. A peer-reviewed publication of R.Boukhanouf\(^1\) focusing on thermal analyses and cooling of a Radio Frequency (RF) electronics package has been used as the basis for this validation case. Reasonable assumptions and approximations have been made to bridge uncertainty in the publication.

The validation study involves qualitative and quantitative comparisons between SimScale and the commercial CFD code FloTHERM involving:

The battery pack was modeled using the CAD tool Onshape. Necessary assumptions were made to overcome missing/inconsistent geometric data:

The model contains the following parts:

Tool Type: OpenFOAMⓇ

Analysis Type: Incompressible, steady-state analysis with the Conjugate Heat Transfer v2 (CHT v2) and Conjugate Heat Transfer (IBM) solvers.

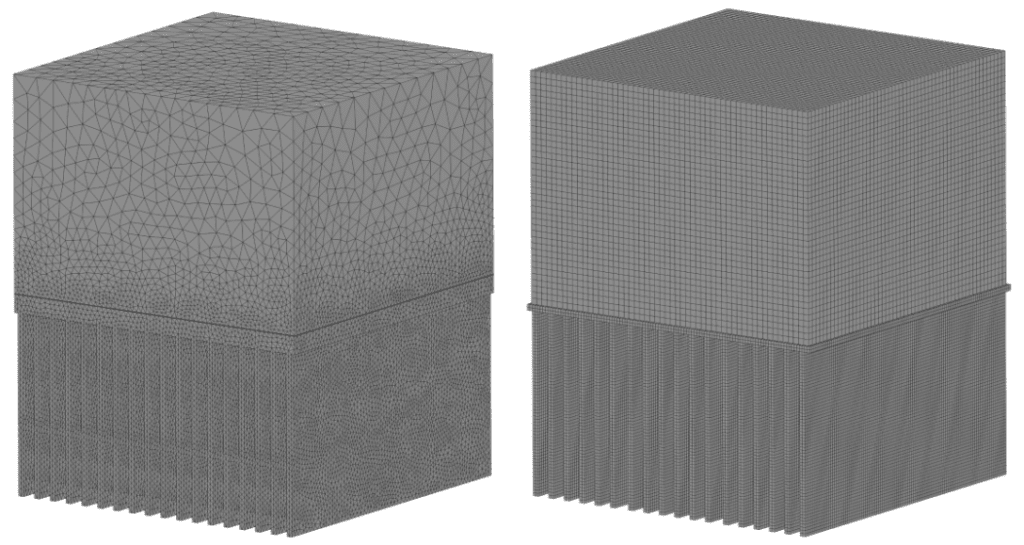

Mesh and Element Types:

The Standard mesher algorithm with tetrahedral and hexahedral cells was used to generate the mesh for the CHTv2 runs. Meanwhile, CHT (IBM) uses cartesian meshes:

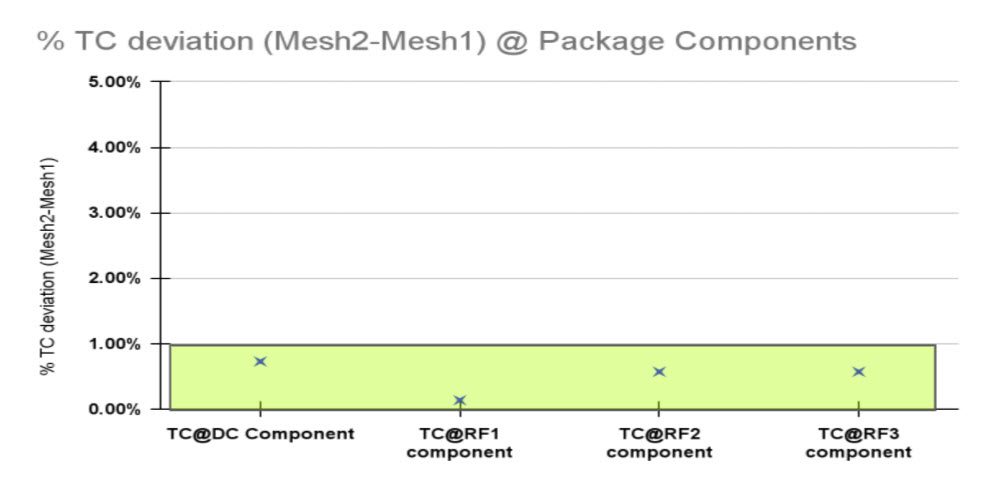

A mesh sensitivity analysis has been carried out to determine the dependence of the CHTv2 solver temperature predictions on the mesh:

| Mesh Count | Mesh Type | TC@DC Component \([°C]\) | TC@RF1 Component \([°C]\) | TC@RF2 Component \([°C]\) | TC@RF3 Component \([°C]\) | |

|---|---|---|---|---|---|---|

| Mesh 1 | 3.4M cells, 1M nodes | Standard | 106.72 | 148.85 | 88.25 | 88.25 |

| Mesh 2 | 4.4M cells, 1.2M nodes | Standard | 105.95 | 148.65 | 87.75 | 87.75 |

| Absolute TC deviation (Mesh2-Mesh1) | 0.77 | 0.2 | 0.5 | 0.5 | ||

| % TC deviation (Mesh2-Mesh1) | 0.73% | 0.13% | 0.57% | 0.57% |

TC stands for the Temperature in Celsius degrees. The values in the table are area-averaged values over the respective components.

It is indicated that the temperature deviation between Mesh 1 and Mesh 2 was found to be within 1% for all the package components:

Fluid Material:

Solid Materials:

The table highlights the materials and thermal conductivity values used for each component of the RF electronics package:

| Component | Material | Thermal conductivity \(W \over \ (m \times \ K) \) |

|---|---|---|

| Enclosure Box | Aluminum | 180 |

| RF & DC shelves | Copper | 385 |

| Solder layer | Tin | 50 |

| Thermal via circuit | (Derived) | 22 (Derived) |

| TIM | Sil Pad® and Gap Pad® | 2 |

| Dielectric Substrate | Dielectric material | 0.6 |

| PCB | Aluminum | 180 |

The RF components have been modeled as using the thermal resistance network and therefore are not assigned any material properties.

The Heat Ratings and Thermal Resistance values used are respectively as follows:

Boundary Conditions:

Convergence below 1e-3 has been achieved. Calculated physical quantities such as inlet pressure, outlet velocity, and cell average temperatures have also been allowed to converge to stable values.

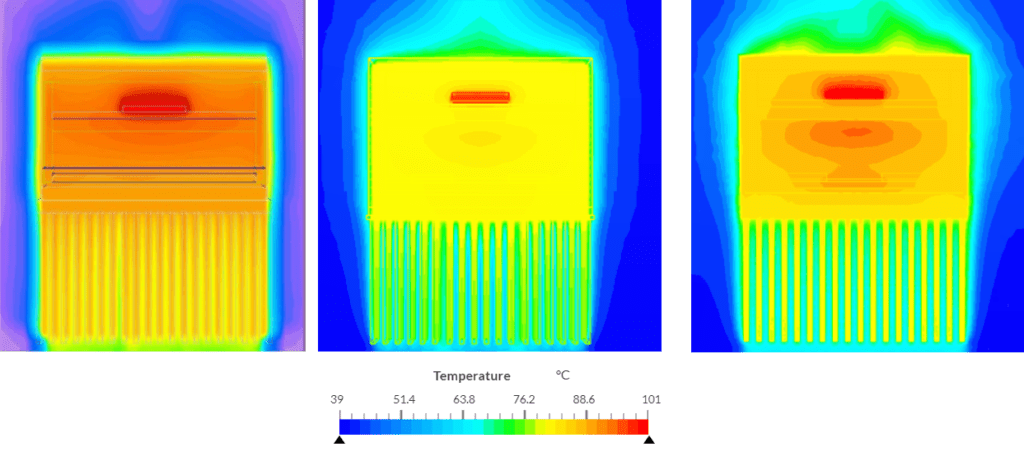

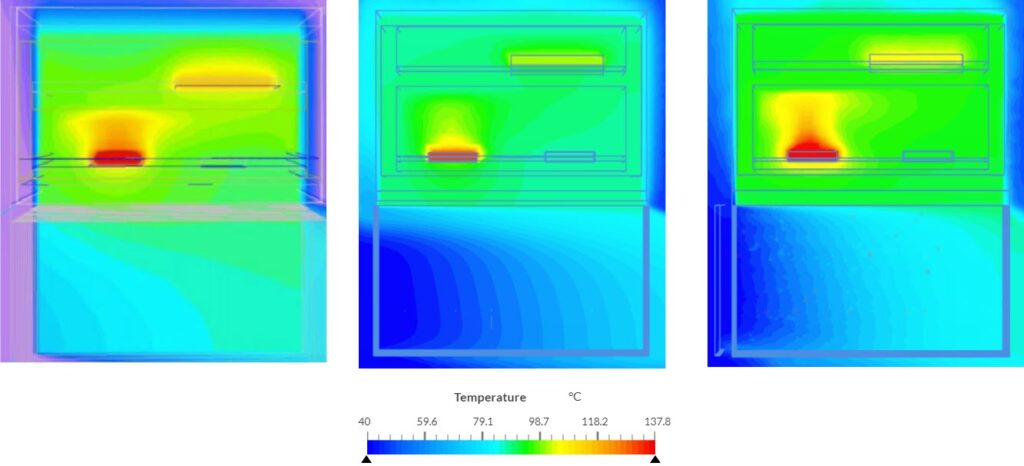

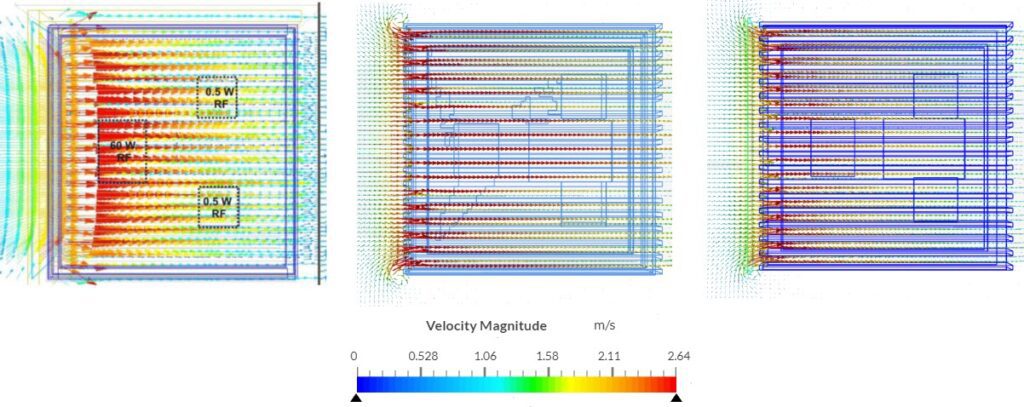

The validation of the SimScale’s CHTv2 has been carried out by qualitatively comparing temperatures and velocities with the reference results\(^1\). The reference results have been produced with the commercial CFD code Flotherm. All post-processing was done in SimScale’s online post-processor:

Another section was compared between the two:

A quantitative comparison of the velocity field shows a good match between the two solvers:

Except from the qualitative comparison, a quantitative study was performed:

| Component | FloTHERM \([°C]\) | CHT (IBM) \([°C]\) | CHT v2 \([°C]\) | TC deviation (CHT IBM – FloTHERM) \([°C]\) | TC deviation (CHTv2 – FloTHERM) \([°C]\) |

|---|---|---|---|---|---|

| TC@DC Component | 101 | 98.46 | 105.95 | -2.54 | 4.95 |

| TC@RF1 Component | 137.85 | 133.77 | 148.65 | -4.08 | 10.8 |

From Table 3 and Figure 7 above, the DC and RF1 component temperatures are within 5% and 8% of the reference FloTHERM results respectively.

This deviation could be traced down to two possible factors:

Overall, The study shows a moderately good agreement between the temperature predictions from the two CFD solvers.

References

Note

If you still encounter problems validating you simulation, then please post the issue on our forum or contact us.

Last updated: September 8th, 2023

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now