Documentation

This case validates the thermal management inside an LED against the CFD and experimental results obtained in the conference paper, “Thermal Analyses and Measurements of Low-Cost COP Package for High-Power LED”\(^1\), using the Conjugate Heat Transfer v2.0 analysis type in SimScale.

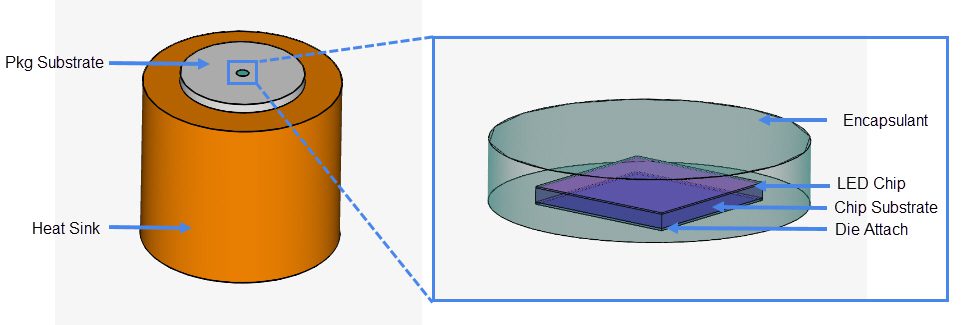

The geometry consists of a cylindrical LED module constructed using the images from the conference paper\(^1\) with certain thickness assumptions for the Silicone encapsulant and the Aluminum Pkg substrate.

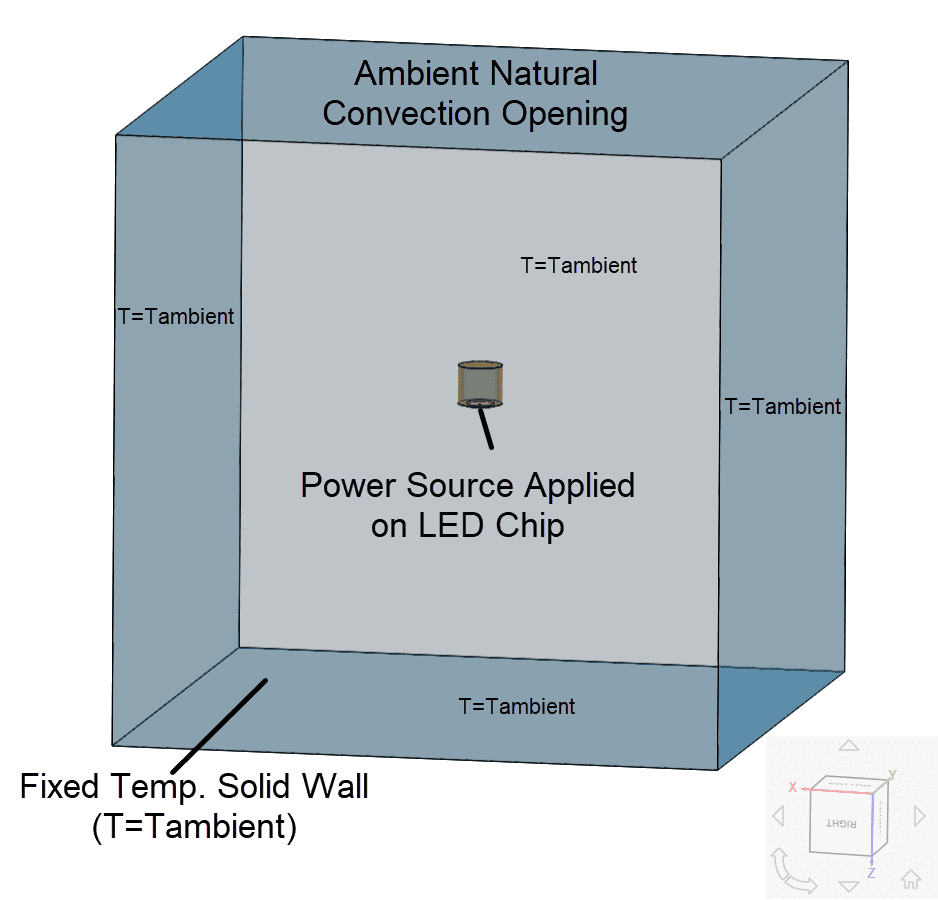

A cubic domain, with seven times the size of the LED module, is also constructed to model the air region surrounding the module in each direction.

Tool Type: OpenFOAM®

Analysis Type: Incompressible, steady state Conjugate Heat Transfer v2.0,

Turbulence Model: Laminar flow

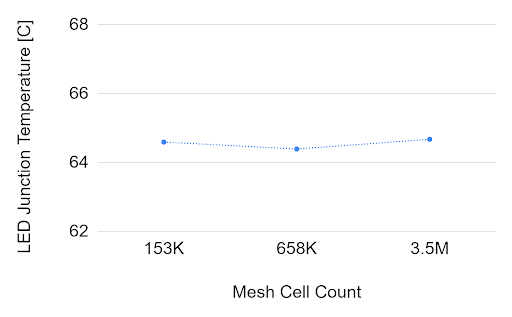

Mesh and Element Types: The mesh is generated using the standard meshing algorithm in SimScale.

| Mesh | Number of cells | Element type |

| F0 (Coarse) | 153000 | Tetrahedral and hexahedral |

| F5 (Moderate) | 658000 | Tetrahedral and hexahedral |

| F8 (Fine) | 3500000 | Tetrahedral and hexahedral |

Solid: The materials constituting the LED are tabulated with their properties as follows:

| Materials | Thermal conductivity \([W/m\ °C]\) | Mass density \([kg/m^3]\) | Specific heat \([J/kg\ °C]\) |

| Silicone (Encapsulant) | 0.3 | 1200 | 2000 |

| LED Chip | 42 | 2330 | 712 |

| Sapphire (Chip substrate) | 35 | 3980 | 761 |

| Ag epoxy (die attach) | 8 | 2300 | 671 |

| Aluminum (Pkg substrate) | 220 | 2702 | 910 |

| Thermal Grease | 3.6 | 1180 | 1044 |

| Copper (Heat sink) | 380 | 8800 | 380 |

Fluid: Air

As in the reference paper, all the faces of the LED module are modeled as no-slip walls with the temperature being zero-gradient. All the faces of the air domain are also modeled as no-slip walls with a fixed temperature value of 24 \(°C\) except for the top face which is open for natural convection.

The LED module is placed in the air domain such that the Silicone encapsulant faces the direction in which gravity is modeled (+z axis).

The experiments mentioned in the conference paper\(^1\) were performed at three different input powers: 0.96 \(W\), 1.22 \(W\), and 1.47 \(W\). The paper assumes that only 78% of the input power is transferred into heat, which is uniformly distributed over the entire chip volume. Thus, the LED Chip is modeled as an absolute power source with the values of 0.749 \(W\), 0.952 \(W\), and 1.147 \(W\) respective to the power inputs used in the experiment\(^1\).

You can read more about power sources in SimScale in the following documentation:

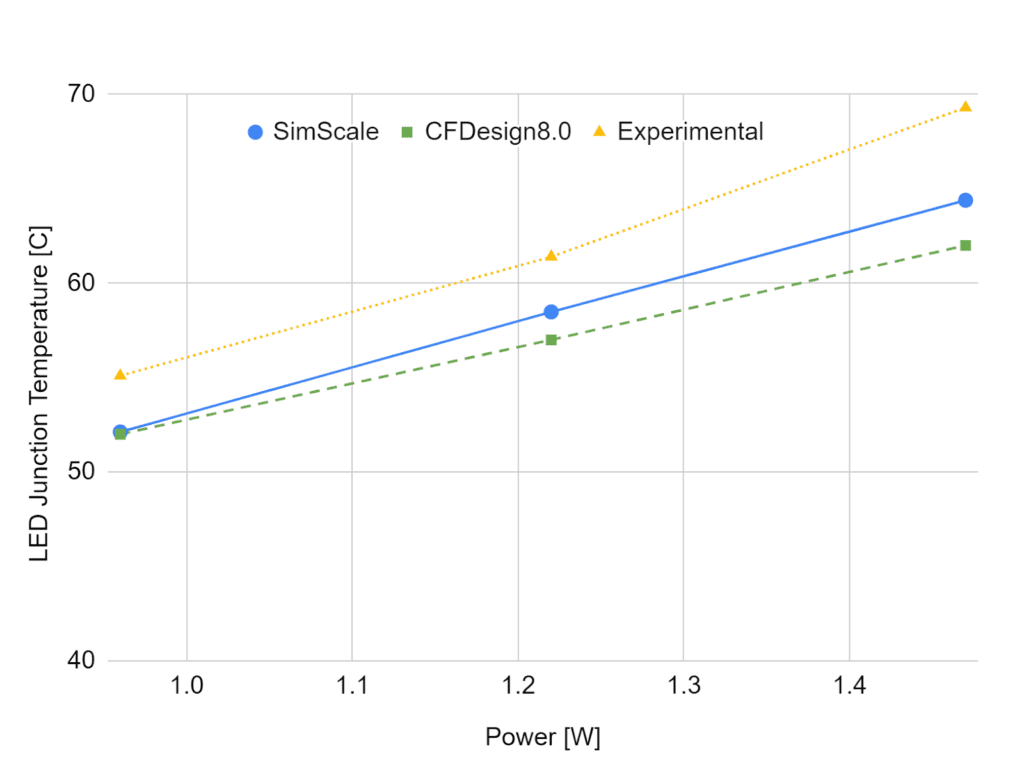

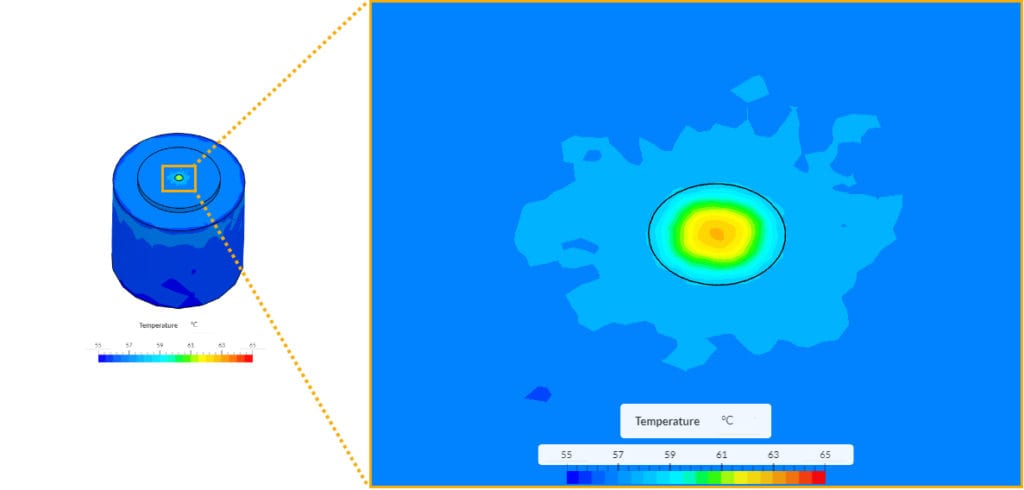

The simulation results from SimScale are compared against the CFD results and experimental results from [1]. The results for the temperature of the surface-junction between LED Chip and Chip Substrate in \(°C\), for various power inputs, are tabulated as follows:

| Power input \([W]\) | SimScale \([°C]\) | CFDesign 8.0 \([°C]\) | Experiment \([°C]\) | % Deviation SimScale | % Deviation CFDesign 8.0 |

| 0.96 | 52.12 | 52 | 55.1 | 5.41 | 5.63 |

| 1.22 | 58.48 | 57 | 61.4 | 4.76 | 7.17 |

| 1.47 | 64.39 | 62 | 69.3 | 7.09 | 10.53 |

For the power input of 1.47 \(W\), a mesh sensitivity study was also performed for meshes with a fineness of 0 (F0), 5 (F5), and 8 (F8). This study is plotted below:

The discrepancy is likely due to the difference between simulation setup and physical testing environment. Unfortunately, full experimental details were not provided in the conference paper.

The following conclusion can be made from this LED performance thermal management validation case:

Last updated: May 5th, 2021

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now