Documentation

This validation case belongs to solid mechanics. The aim of this test case is to validate the following parameters:

The simulation results of SimScale were compared to the results derived from [Treloar]\(^1\).

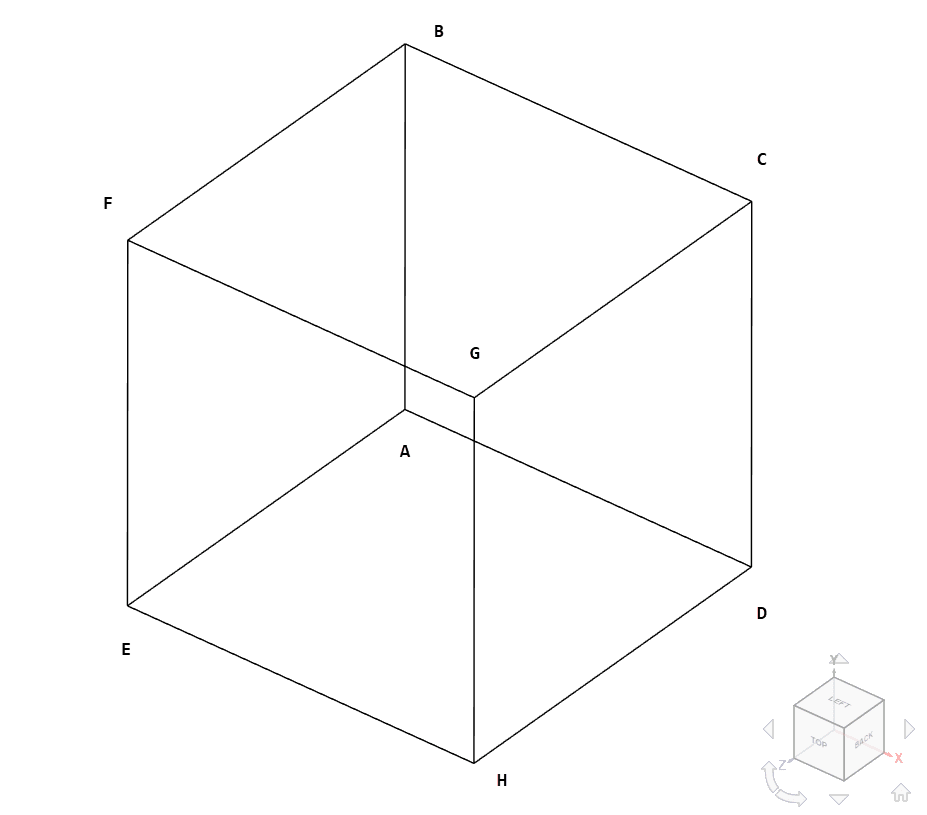

The geometry used for the case is as follows:

The cube has an edge length of 1 \(m\).

Tool Type: Code_Aster

Analysis Type: Static Non-Linear

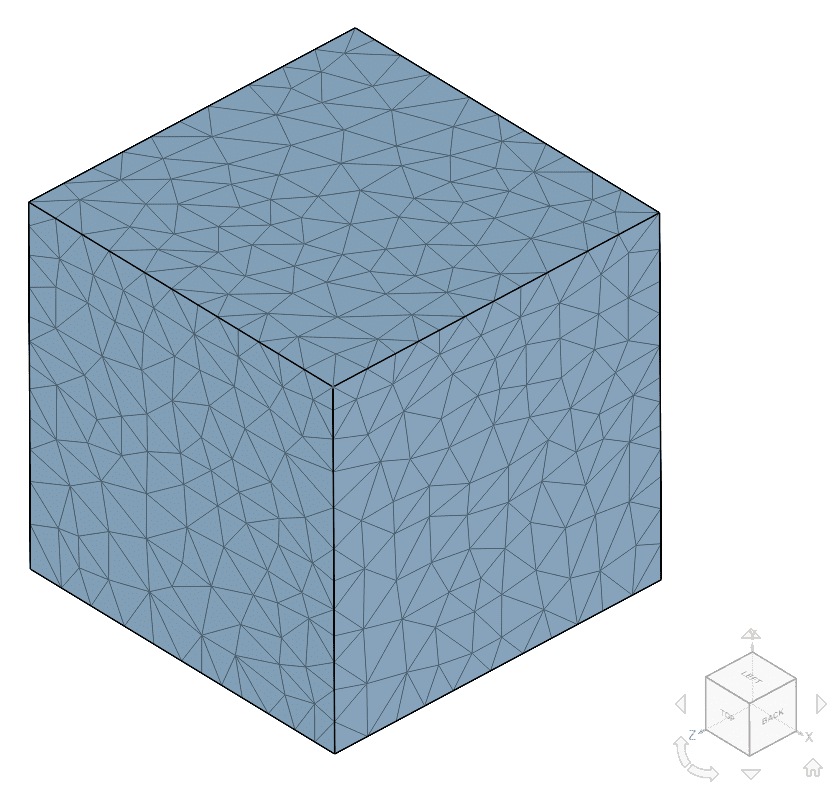

Mesh and Element Types:

The mesh for the cube geometry was computed using SimScale’s Standard meshing algorithm.

| Case | Mesh Type | Number of Nodes | Element Type |

|---|---|---|---|

| All | Standard | 1184 | 1st order tetrahedral |

Material:

Hyperelasticity material, with the following parameters for each type of law:

Boundary Conditions:

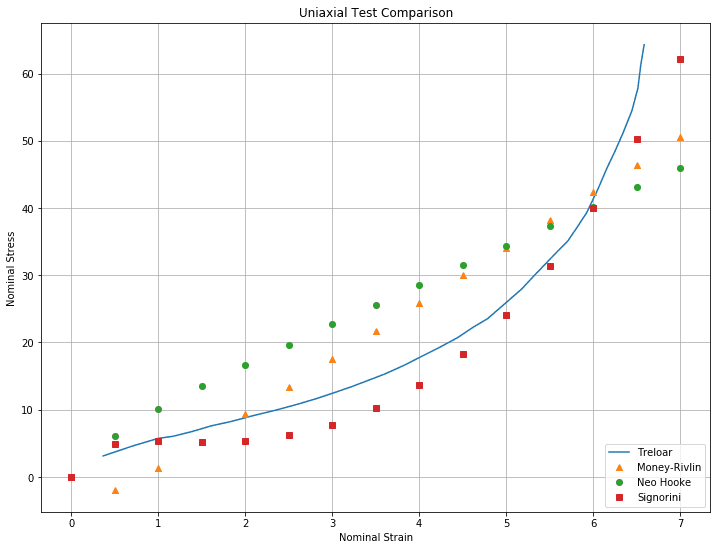

The reference solution is of the experimental type and was extracted from [Treloar]\(^1\). It corresponds with the nominal stress-strain material curve. The values were extracted using WebPlotDigitizer.

Comparison of the nominal stress-strain curves computed from reaction force on the faces with zero displacement, versus the reference data is shown in Figure 3:

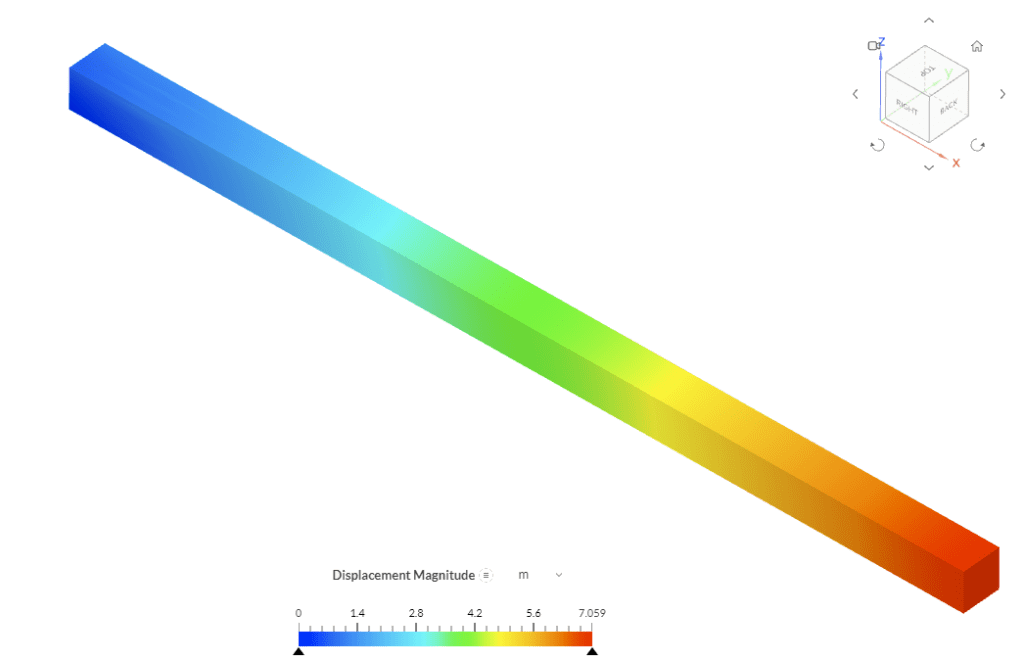

Following is a plot of the final deformed shape from the Signorini case results:

References

Note

If you still encounter problems validating you simulation, then please post the issue on our forum or contact us.

Last updated: July 28th, 2021

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now