Documentation

Vibration analysis is a diagnostic process used to detect, monitor, and prevent mechanical failures in machinery. Engineers perform vibration analysis to examine the vibration signal patterns in a system and find anomalies or changes. They spot any irregularities that may signal upcoming problems, especially for heavy-duty machinery like motors, compressors, and gears [1].

By examining these vibrations, one can learn more about the condition of the machine or structure and decide what maintenance is necessary. Stress, displacement, velocity, eigenmodes, and more can all be calculated and visualized using vibration analysis tools like SimScale, a cloud-native solution that offers seamless workflow integration, handling multiple physics simulations directly in your browser, particularly Finite Element Analysis (FEA), the numerical solution for analyzing vibration.

Thanks to vibration analysis, the lifespan of the machine or structure can be increased. And according to rules set forth by international standardization bodies, a lot of products are required to pass physical vibration testing before they can be approved for safe use. Thus, vibration analysis using SimScale FEA helps reduce the risk of structural failure during the actual vibration testing by providing accurate virtual testing and minimizing the need for physical vibration testing.

Vibration may be caused by various factors, including but not restricted to recurring forces, imbalance, and misaligned machine parts. Displacement, velocity, and acceleration are the three primary vibration measurement variables. These are measured in terms of their magnitudes (or amplitudes), where displacement magnitude is usually measured in millimeters or micrometers, velocity magnitude in millimeters per second, and acceleration magnitude in meters per second squared (or in g’s).

There are primarily two categories of vibrations:

There are many different sources of excitation force for equipment, like roll imbalance, where the center of mass is not aligned with the axis of rotation. Nonlinear processes like vibration suppression and deterministic chaos have also been studied [3]. A versatile instrument, vibration analysis is essential for quality assurance, maintenance, and diagnostics.

Physical vibration analysis involves a systematic process to monitor and identify faults in machinery. The steps include [1]:

In engineering design, while physical testing is vital, it can be quite costly and time-consuming, especially when multiple tests for different variables are required. This is where engineering simulation plays a significant role.

With SimScale’s cloud-native simulation, engineers can run multiple simulations in parallel, setting up varying real-world scenarios of vibration. This enables them to minimize the testing time significantly while maintaining high-quality data analysis using FEA solvers. As a result, the steps for vibration analysis in a simulation environment would take the following shape:

A variety of techniques can be utilized to analyze vibration data. These can be defined as the following:

SimScale is a powerful vibration analysis tool for engineers as it offers structural mechanics simulation capabilities reinforced with cloud computing. This allows for cloud-native simulation capabilities that enable:

One of the many capabilities of SimScale is to analyze vibration patterns and find irregularities in mechanical systems. SimScale’s FEA modal (frequency) analysis, powered by the Code Aster solver, enables the computation of natural frequencies of a structure and the corresponding oscillation mode shapes. It can help identify the eigenfrequencies (eigenvalues) and eigenmodes (mode shapes) of a structure under vibration. Furthermore, SimScale’s adaptability isn’t restricted to simple shapes; it also includes support for a variety of CAD file types and validation in typical engineering settings, such as the random vibration response of cantilever beams. For more information about why we need vibration analysis and why SimScale is the appropriate tool for that, check out our application page on Vibration Analysis Simulations.

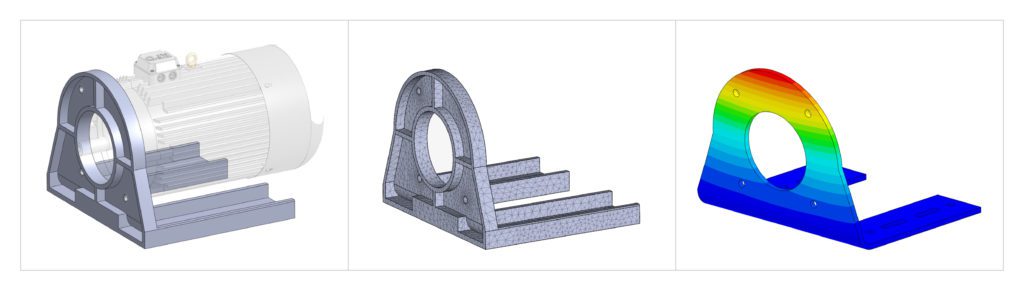

SimScale enables vibration analysis across various industries and application areas, including automotive, aerospace, consumer products, and machinery and industrial equipment. One example from the automotive industry is the vibration analysis simulation of an electric motor bracket using SimScale. Here, it is important to examine the bracket’s structural characteristics in order to confirm that its critical response frequencies fall within the designated operational range.

This simulation study’s design objective is to enhance the electric motor support bracket such that its natural frequencies stay outside of the motors’ running speeds, preventing potential part damage, bolt loosening, reduction in clearances between parts, and unwelcome noise. Through this examination, engineers can make sure that the electric motor bracket is stable and efficient for the duration of its operational life.

Figure 3 below shows the simulation workflow from CAD geometry to post-processed simulation results. Upon simulation, numerous statistical data would be available to further examine the bracket’s eigenmode number, eigenfrequency, Modal Effective Mass (MEM), Normalized Modal Effective Mass, and cumulative Normalized Modal Effective Mass (CNME). Furthermore, multiple CAD variants of the bracket can be visualized and simulated in SimScale simultaneously to find the optimal geometry that enables the furthest eigenfrequency value from the speed of the rotating shaft, thus minimizing the risk of possible failure due to vibration.

Vibration can be measured, analyzed, and controlled with the appropriate set of tools. Vibration analysis simulation can now be used as a predictive tool in your engineering toolbox for optimized designs, better structural integrity, and more efficient operation thanks to structural analysis tools in SimScale.

SimScale provides a user-friendly interface and a cloud-based architecture in addition to its extensive toolkit, enabling real-time collaboration and fast upgrades. It’s more than simply a platform; it’s an ecosystem that regularly develops and updates to match the needs of a technological environment that is rapidly changing.

References

Last updated: August 28th, 2024

We appreciate and value your feedback.

What's Next

What Is Heat Transfer?Sign up for SimScale

and start simulating now