Documentation

A linear elastic material is a mathematical model used to analyze the deformation of solid bodies. It is useful to compute the relation between the forces applied on the object and the corresponding change in shape. In other terms, it relates the stresses and the strains in the material.

For a deformation process to be considered linear and elastic, the following conditions must be met:

A linear elastic material can be seen as the generalization of Hooke’s law for a spring:

$$ F = Ku \tag{1}$$

where:

In order to get rid of the geometry dependency of the stiffness, for the sake of generalization, the relation between force and deformation is expressed in terms of stress and strain:

$$ \sigma = \frac{F}{A} \tag{2}$$

$$ \varepsilon = \frac{u}{L} \tag{3}$$

where:

By using these terms, the one-dimensional linear elastic relation can be expressed as:

$$ \sigma = E \varepsilon \tag{4}$$

where \(E\) is Young’s modulus of the material, the proportional relation between stress and strain:

In the general case of a solid object subject to loads in multiple directions in space, the one-dimensional relation presented above is no longer sufficient to describe the deformations. In three dimensions, stress and strain are expressed as tensor quantities:

$$ \sigma = \begin{bmatrix} \sigma_{xx} & \tau_{xy} & \tau_{xz} \\ \tau_{yx} & \sigma_{yy} & \tau_{yz} \\ \tau_{zx}& \tau_{zy} & \sigma_{zz} \end{bmatrix} \tag{5} $$

$$ \varepsilon = \begin{bmatrix} \varepsilon_{xx} & \frac{1}{2}\gamma_{xy} & \frac{1}{2}\gamma_{xy} \\ \frac{1}{2}\gamma_{yx} & \varepsilon_{yy} & \frac{1}{2}\gamma_{yz} \\ \frac{1}{2}\gamma_{zx} & \frac{1}{2}\gamma_{zy} & \varepsilon_{yy} \end{bmatrix} = \frac{1}{2}(\nabla_X u + \nabla_X u^T) \tag{6} $$

Where \(\nabla_X\) is the gradient operator computed in the undeformed configuration and \(u\) is the vector of deformations in the material:

$$ u = \begin{bmatrix} u_x \\ u_y \\ u_z \end{bmatrix} \tag{7} $$

The general form of the stress-strain relation can be written as:

$$ \sigma = \frac{E}{1+\nu} \Big( \varepsilon + \frac{\nu}{1 – 2\nu} Tr(\varepsilon) I \Big) \tag{8}$$

Or solved for the strain:

$$ \varepsilon = \frac{1 + \nu}{E} \Big( \sigma – \frac{\nu}{1 + \nu} Tr(\sigma) I \Big) \tag{9}$$

where \(\nu\) is the Poisson’s ratio, which relates normal stresses with deformations in the perpendicular directions. Here, it is assumed that the material is isotropic and homogeneous, which means that the material properties such as \(E\) and \(\nu\) are constants with respect to position and orientation.

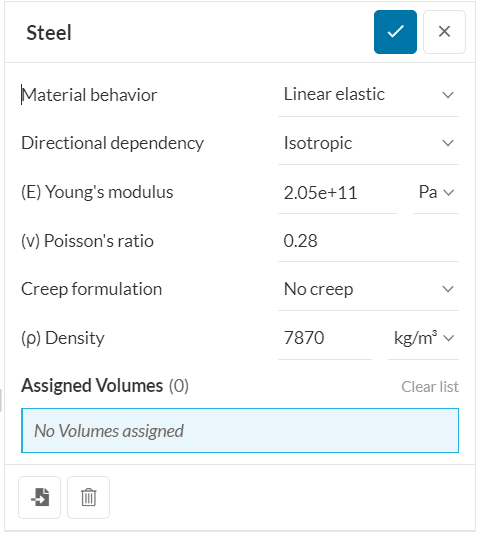

For the application of a linear elastic material in a structural simulation, the following set of parameters must be specified:

In the Workbench, go to Materials, confirm the Material behavior to Linear Elastic, set the successive parameters and assign them to a volume:

Beyond Linear Elastic Materials

For most of the structural analysis involving metals such as steel and aluminum, if the stresses are below yield strength, linear elastic material model shall be used. However, this model is incapable of truly describing the material behaviour, if the objective of the analysis is to study plasticity. In that case, use Elasto-plastic material model for the analysis. Additionally, there are also materials such as rubbers and elastomers for which the relationship between stress and strain is nonlinear while deforming elastically. For such materials, Hyperelastic material model is the most appropriate choice.

Last updated: December 28th, 2023

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now