Documentation

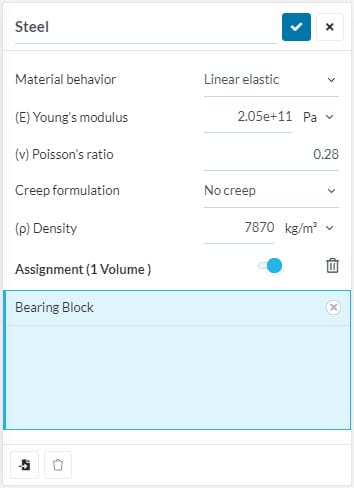

In the materials section, you can define multiple materials and assign volumes to them. To do so, click on the ‘+’ button next to Materials.

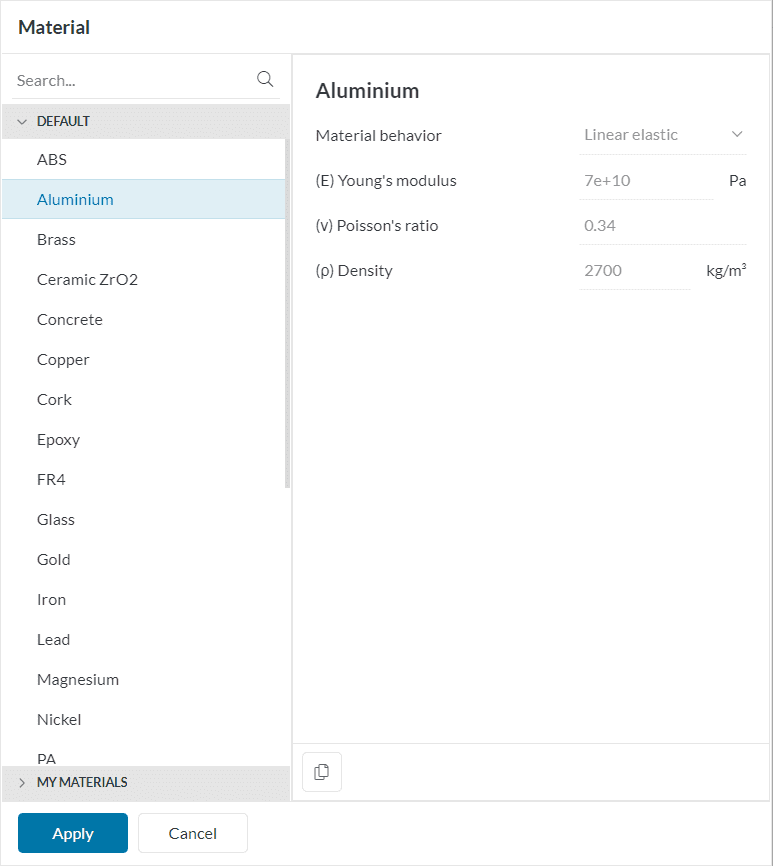

Afterwards, a library of materials appears. Select one material from the list. The specific material parameters to be defined depend on the analysis type of the simulation.

Material parameters can be changed once a material is assigned to a simulation domain. If you will be using the same material again and it’s not in the default list, we recommend you to create a User Material that can be used in any of your simulations.

Materials can also be uploaded and shared amongst all users at your company. This allows all your users to reference the same material data and ensure consistency across simulations. Please reach out to us if you would like to learn more!

For solid mechanics analysis, every volume that belongs to the simulation domain has to be assigned to exactly one material. For example, in the case of a solid mechanics simulation, you have to choose a material law that describes the relationship between the strains and the consequent stresses. Please be aware that the material behavior can be linear or nonlinear (e.g. plastic material) and therefore may affect the numerical effort of the calculation. Solid material properties and behavior are defined by a thermal solid model.

Find below the solid material models available on SimScale:

Linear elastic material deforms elastically throughout the analysis, which means that it will return back to its initial state upon unloading, irrespective of the deformation.

Elasto-plastic material model describes an elastic behavior until the onset of plasticity after which the solid material undergoes irreversible deformation when subjected to loading.

Hyperelastic materials are a special class of materials that tend to respond elastically when they are subjected to very large strains. They show both nonlinear material behavior as well as large shape changes.

Creep is the inelastic, irreversible deformation of structures over a long period of time. It is a life-limiting factor and depends on stress, strain, temperature, and time.

Damping, in dynamic simulations, means energy dissipation out of the system. It can be used to remove unphysical oscillations of the system or to mimic effects such as internal friction of the material.

Definition of Young’s modulus and Poisson’s ratio can be found in the following documents respectively:

All incompressible analysis types require the material density (a constant) to be specified by the user. For compressible simulations, the density is solved as part of the equation of state and does not need to be provided in the material definition. Fluid material properties and behavior are defined by the thermophysical fluid model.

Assigning vacuum as the material medium

Yes! You heard it right! In SimScale it is possible to create a vacuum medium by changing the conductivity of air. Follow the steps:

Warning

In single region simulation types (incompressible, compressible, and convective heat transfer), the material can only be assigned to a fluid region. Assigning a material to topological entity sets or advanced concepts will lead to a warning message preventing you from performing the simulation.

For analysis types that do not include energy/heat, the fluid materials are categorized based on the viscosity model of the fluid. The models generally relate the behavior of viscosity to the strain rate of the fluid. The 2 fundamental types of viscosity models that define any fluid material are as follows:

Newtonian Model

In a Newtonian fluid model, the local stresses due to the viscous forces in the fluid change linearly with the local strain rate. Here, viscosity is then the constant of proportionality. The implemented Newtonian model assumes a constant kinematic viscosity

Non-Newtonian Model

In a non-Newtonian fluid model, the local shear stress and the local shear rate of the fluid are not related linearly. Here, a constant of proportionality cannot be determined and so viscosity is a variable quantity. For these fluids, several non-Newtonian models exist that define the non-linear relation to determine the kinematic viscosity, ν (see link below for details). Some examples of non-Newtonian fluids include common substances like ketchup, custard, toothpaste, corn-starch suspensions, paint, blood, and shampoo.

Last updated: September 14th, 2022

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now