Documentation

Physical (or “nonlinear”) contacts enable you to calculate realistic contact interaction between two parts of the assembly. Also, it allows calculating the self-contact between different faces of the same part. Unlike linear contacts, those faces are not just connected via linear relations but the actual contact forces are computed.

To enable a nonlinear interaction, you have to define contact pairs of faces or face sets. For those faces the distance between each other is tested during the simulation, and, in the case that a face pair gets in contact, the interaction forces are taken into account, preventing those faces from interpenetrating each other. As those forces only occur in the case of contact the interaction is a nonlinear phenomenon and thus only applies for nonlinear analyses.

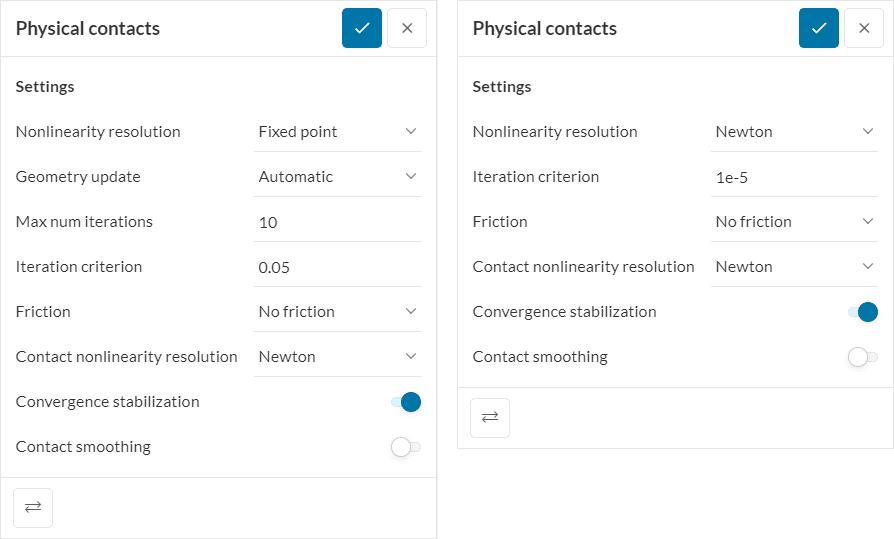

The Physical contacts settings panel offers the following choices:

The physical contact solution algorithm works by performing two independent steps:

Contact Pressure Field

The contact pressure field can be queried to the solver under Result Control Item > Solution fields > Contact type > Pressure. This field will only be non-zero on the slave assignment of the contact pairs.

Heat Transfer

In Thermomechanical Analysis , the physical contacts do not transfer heat. If you would like to add heat transfer, you need to create an additional bonded contact with heat transfer only option. Of course, this scenario considers the faces to be in perfect thermal contact, even if they are not mechanically in contact.

The following general parameters are available for the global physical contact algorithm:

For each contact pair definition, click on ‘+’ next to Physical contacts and the following parameters are available:

To learn more about this physical contact setting and prediction of the coefficients, please check this article.

| Case | Initial State | Fictitious Clearance | Final State |

| 1 | 2 \(mm\) GAP | 1 \(mm\) | 2 \(mm\) GAP (no contact active) |

| 2 | 2 \(mm\) GAP | -1 \(mm\) | 2 \(mm\) GAP (no contact active) |

| 3 | 2 \(mm\) GAP | 3 \(mm\) | 3 \(mm\) GAP (contact active) |

| 4 | 2 \(mm\) OVERLAP | 1 \(mm\) | 1 \(mm\) GAP (contact active) |

| 5 | 2 \(mm\) OVERLAP | -1 \(mm\) | 1 \(mm\) OVERLAP (contact active) |

| 6 | 2 \(mm\) OVERLAP | 3 \(mm\) | 2 \(mm\) OVERLAP (contact inactive) |

In a penalty contact solution method the contact interaction between the bodies is handled via spring elements that model the stiffness of the contact. Hence, in a penalty approach, the faces in contact may penetrate each other slightly depending on the defined contact stiffness that couples the interpenetration with the consequential reaction forces.

It is called the Penalty method because the interpenetration creates forces that act to prevent further intersection, penalizing this behavior.

The Contact stiffness is defined by the coefficient of the linear penetration model. The higher the penalty coefficient, the stiffer the contact gets, which is desired in most cases, as bodies usually are not intended to penetrate at all.

There are four options for contact stiffness: low, moderate, high, and custom. The larger the contact stiffness, the less interpenetration is observed. However, convergence becomes increasingly more difficult for larger penalty coefficients. A trade-off between realistic behavior and optimization for convergence needs to be found.

When using a low contact stiffness, the penalty coefficient receives a value 50 times larger than the Young’s Modulus of the softest material that takes part in a given contact. With a moderate and high contact stiffness, the penalty coefficient receives a value 200 and 1000 times larger than the Young’s Modulus of the softest material, respectively.

With a custom contact stiffness, the user can choose any value for the penalty coefficient.

Note

Once the simulation is finished, check the contact faces in the results. If you observe a significant penetration, increase the penalty coefficient and re-run the simulation. Optimally, one would increase the penalty coefficient (for example, by a factor of 10x at a time with a custom definition) until the penetration is insignificant.

In the Augmented Lagrange contact solution method the contact interaction between the bodies is handled via additional Lagrange equations that account for the contact conditions. As opposed to the penalty method, the contact equations are solved exactly and thus no penetration between the contact faces may occur.

Important

Although the Lagrangian contact gives generally more accurate results than the penalty contact, it is not as robust. Also the additional Lagrange equations introduce new DOFs which will increase the system size and thus the solution time.

During nonlinear simulations including physical contacts, you are provided with contact monitoring plots which will keep you in the loop on contact penetration and solution convergence, giving you confidence and control over your result outputs.

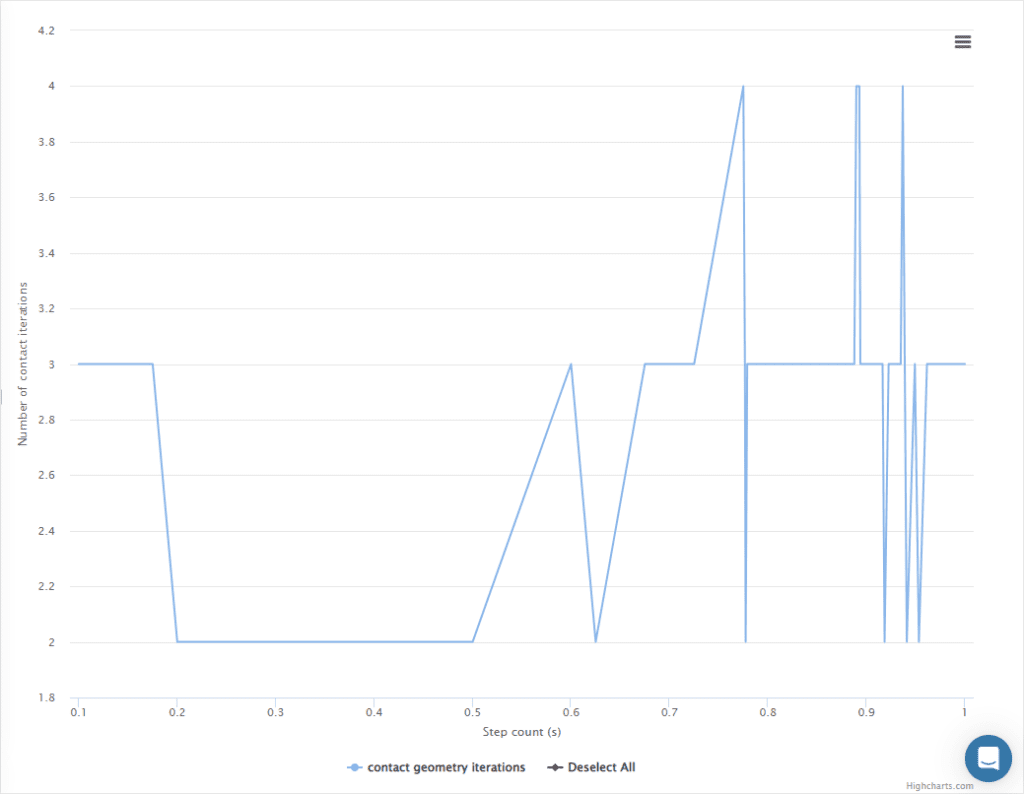

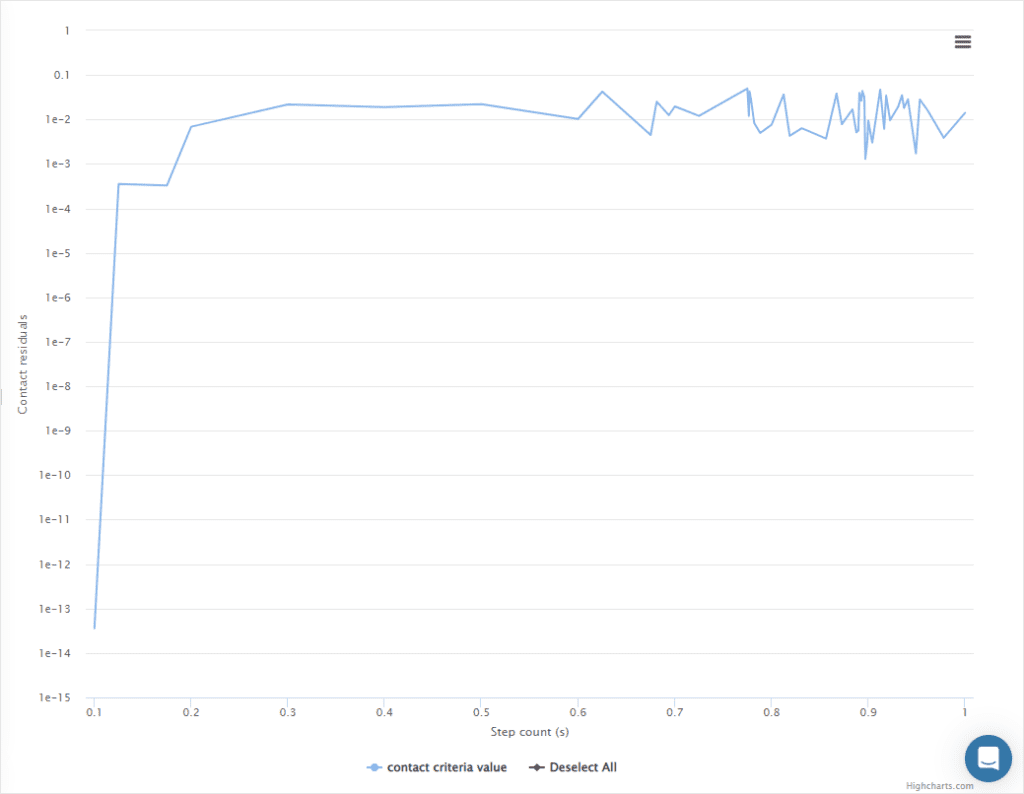

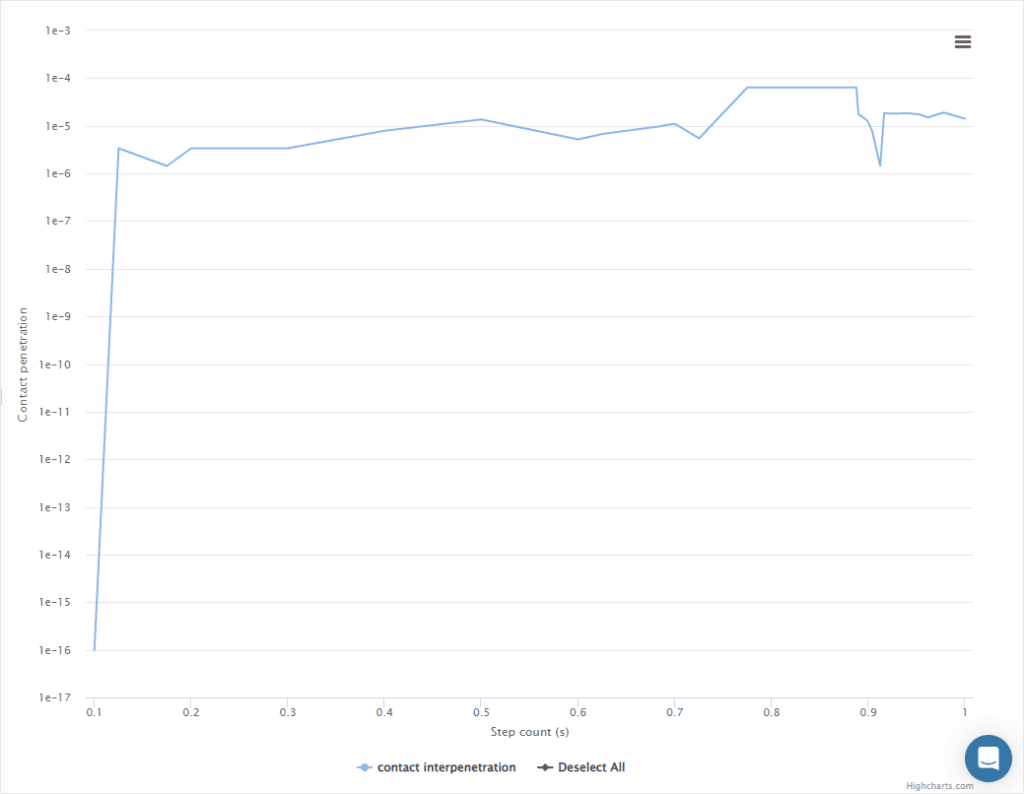

The following plots will be available under the simulation run, and will be updated as the computation advances:

This plot presents the number of fixed point iterations that were performed for convergence to be achieved at each load or time step.

This plot presents the contact residual at the last fixed point iteration of each time or load step when convergence is considered to be achieved according to the iteration criterion.

This plot presents the sum of all penetrations in physical contact pairs, each one measured as the distance between a node in the slave surface and the master surface, in units of length, when the node enters the volume of the master surface.

Last updated: June 24th, 2024

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now