Documentation

In a Conjugate Heat Transfer v2.0 (CHT v2.0) analysis, an interface defines the physical behavior between the common boundaries of two regions that are in contact, e.g. solid-solid, or solid-fluid.

Important

In conjugate heat transfer simulations, all the fields at the interfaces are fully constrained by the Interface type. Therefore, defining boundary conditions to faces assigned to interfaces is not allowed. This would result in an overconstrained model.

If an interface is assigned to a boundary condition, the following error message is displayed when the user tries to start a simulation:

To solve this error, the user needs to unassign the interfaces from the boundary conditions.

Additionally, interfaces between two flow regions are not possible and will result in an error when running simulations.

When creating a new CHT v2.0 simulation, all possible interfaces will automatically be detected and populated in the simulation tree. Interfaces will be grouped together and defined as Coupled thermal interface.

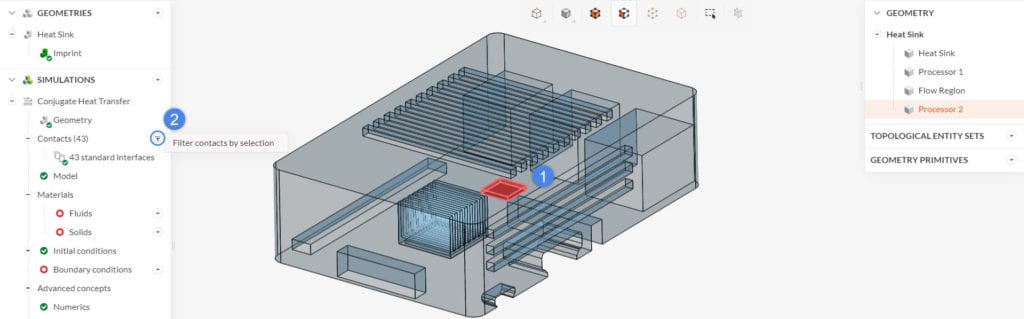

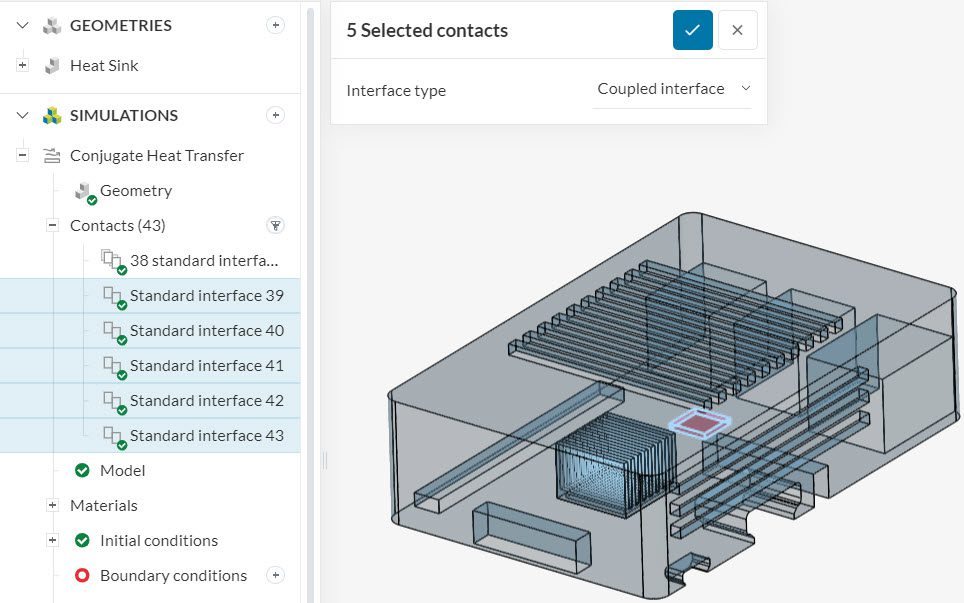

Individual interfaces or a group of interfaces can be filtered via entity selection. Select the entities (faces or volumes) for which you want to select all interfaces that exist between them.

Once you filter the interfaces of interest, a window opens with additional options for the Interface type for the selected contacts.

Interfaces which differ in settings from the standard bulk interfaces group will stay exposed individually in the simulation setup tree.

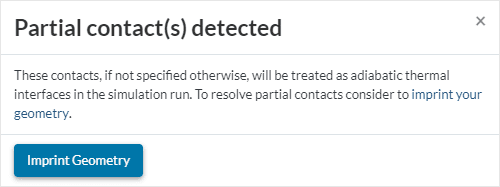

An interface is required to always be defined between two congruent surfaces, meaning that these surfaces must have the same area and overlap completely. After contact detection, the platform will also perform a check for partial contacts. If partial contacts are detected, the platform will show a warning and recommend an imprinting operation.

Imprinting is a single-click operation built into SimScale, which splits existing faces into smaller ones in order to guarantee perfect overlap between contacting faces. It is recommended to perform an imprint operation in order to guarantee accurate heat transition modeling for the simulation.

By default, any detected partial contact will be defined as an adiabatic interface, and not participate in heat conduction unless specified otherwise.

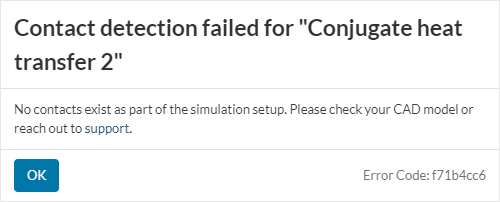

As all possible interfaces are detected automatically, it is no longer possible to manually add an interface or to change the entity assignment for a specific interface. In case no interfaces can be detected automatically, SimScale will show an error message.

In this case, it is not possible to create a mesh or start a simulation run for this simulation. Instead, the CAD model needs to be investigated for potential errors that prevent successful contact detection. Some common causes are:

Some of the fix operations described above can be performed in the CAD mode. You can also reach out to support via email or chat in case you encounter this issue and can not solve it using the above suggestions.

The Interface type options define the heat exchange conditions at the interface. The types available for the interfaces in CHTv2 are reported below:

Attention

In case the Conjugate Heat Transfer v2.0 solver is used with radiation enabled, the contact type options are limited to ‘Coupled’ interface.

The coupled thermal interface models a perfect heat transfer across the interface. This is the default setting, in case an interface is not defined by the user.

The Thin layer resistance allows modeling a layer with thickness

For example, it is possible to model the thermal paste between a chip and a heat sink without needing to resolve it in the geometry. Adding a thin layer to the geometry and meshing it is a problem, considering that the thickness of these layers is two or three orders of magnitude smaller than other components in the assembly.

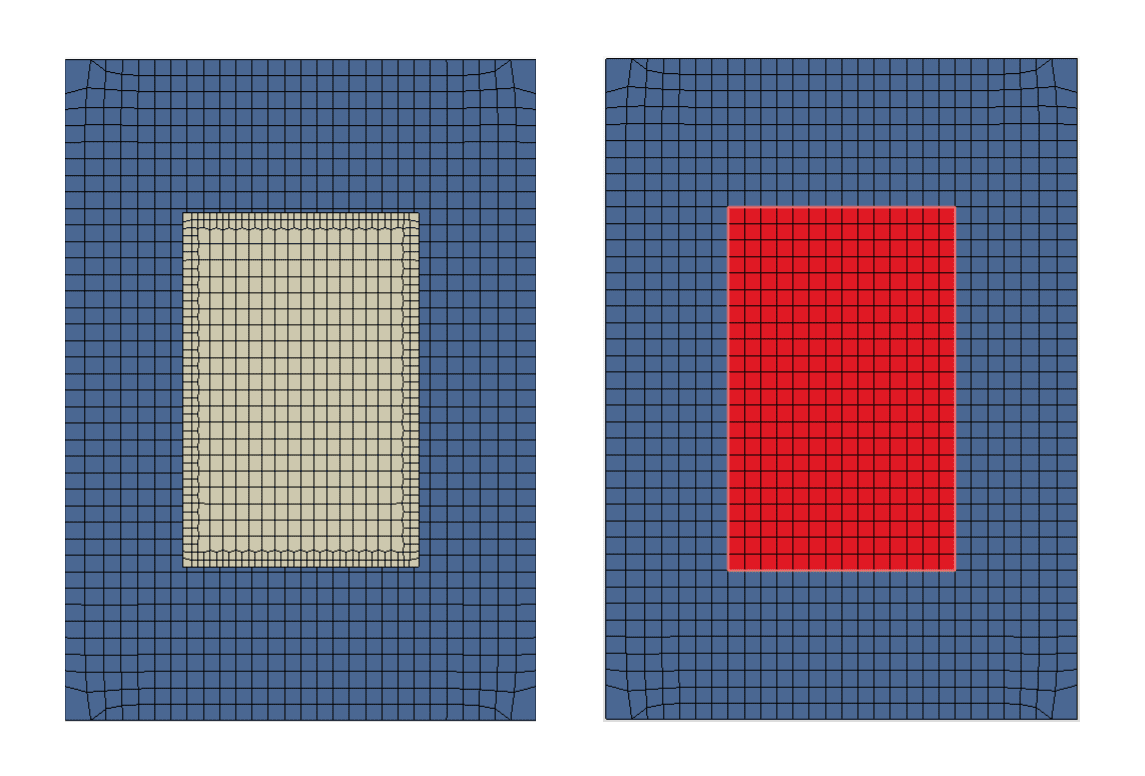

A conjugate heat transfer simulation always requires a multi-region mesh. As far as the mesh is concerned, it is fundamental that the cell size at the interface is similar between the two faces. As a rule of thumb, the cells on one face should be less than 1.5 times the size of the others. The figure below shows an example of this issue. In the left case, the cells at the interface on the inner region are too small with respect to those on the outer body. In the case on the right side, the cells on the interface are approximately the same size.

Last updated: November 13th, 2024

We appreciate and value your feedback.

Sign up for SimScale

and start simulating now