Solero Technologies is a pioneer in designing and manufacturing automotive components, known for its high-performance transmission solenoid valves, engine solenoids, stop-start accumulators, and hydraulic control modules. Recent product development and launches of active suspension and electrification components are diversifying the market for Solero Technologies. For more than 50 years, Solero Technologies has customized engineering and fabrication to keep its solenoid and control products at the forefront of the industry with a reputation for its quality, precision, and safety. The engineering team at Solero Technologies provides full service from design to testing/validation and through to manufacturing, as the company is a top-rated tier 1 supplier to major OEM suppliers in the automotive industry.

High precision, pressure-regulating solenoids help automotive transmissions run smoother, contributing to cleaner and more efficient vehicles, longer vehicle life cycles, and a healthier environment. The valves need to be robust, durable and have a long life. Electro-mechanical solenoid valves and Hydraulic Control Modules (HCM) for planetary, continuously variable transmission (CVT), and hybrid transmission architectures are the main expertise at Solero Technologies, which specializes in the following types of products.

The electromechanical solenoid valves regulate various functions in a vehicle, primarily controlling the flow/pressure of the transmission fluid for clutch control through the engine. Recent innovation development projects include the design of valves of active suspension and electrification components readying for product launch.

This level of precision engineering means there is little to no room for errors in design and manufacturing. Solero Technologies has been using SimScale to optimize the design and performance of its products before they get to the testing and validation stages. The latter is part of a heavily regulated automotive supply chain that places safety, precision performance, and durable products at the heart of a fast-moving automotive industry.

The engineering team at Solero Technologies is powered by computer-aided engineering (CAE) tools that feed into advanced processes, including prototyping, custom engineering, product development, and fabrication. As part of the prototyping process for each customer, the team maps out a testing and validation plan to ensure overall functionality, durability, and performance. Optimizing and thoroughly evaluating design performance at the simulation stage reduces the risk of errors and the high cost of redesign and testing later on. This makes simulation earlier in the development process a critical step at Solero Technologies.

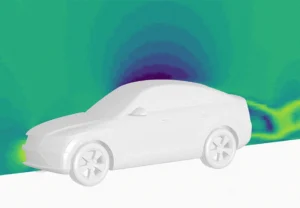

The simulation team at Solero Technologies is led by Chandru Rao, Simulation Manager. The CAE workflow uses STEP files of the valve geometry imported into SimScale to build their simulation models. In one of their recent projects, the team has been using SimScale to optimize flow and pressure to eliminate restrictive flow. Valve performance is highly sensitive to small changes in the flow/pressure field, which requires many precise simulation iterations to decipher marginal gains in performance compared to the cost of prototyping the new design.

The solenoid is effectively an electro-mechanical linear motor driving a rod that moves back and forth to open/close channels for fluid movement. The valve in question has an inlet for the transmission fluid as standard, and a flow diversion to a side-volume is added to moderate the pressure build-up before the outlet (to reduce pressure drop across valves). Simulations are set up to evaluate the pressure distribution inside the valve and to find the optimum length of the valve flow channels. The hole into the side opening needs to be evaluated for optimum size and pressure drop.

We have been using SimScale to modify and develop new solenoid valves. SimScale is one of our reliable computational tools to solve our fluid problems to make sure our solenoid-valves fluid performance is reliable.

Chandru Rao

Manages the simulation needs at Solero Technologies

The above simulations have resulted in proprietary solenoid valve improvements that are moving through the R&D and production process. Using SimScale earlier in the design process has allowed Chandru and his team to evaluate a larger number of CAD designs and disqualify poor-performing geometry variants quicker and more cost-effectively.

Sign up for SimScale

and start simulating now