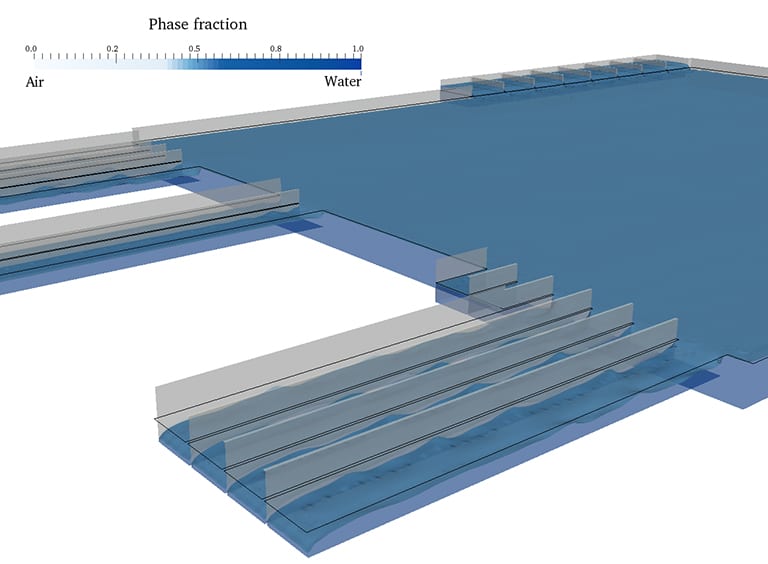

The engineers at Sogea Maroc needed to investigate the design of a water treatment facility basin and check for any possible disturbance phenomena as well as determine the overflow of the structure based on the provided operating conditions (inlet flows and maximum outlets) with the filling of the basin.

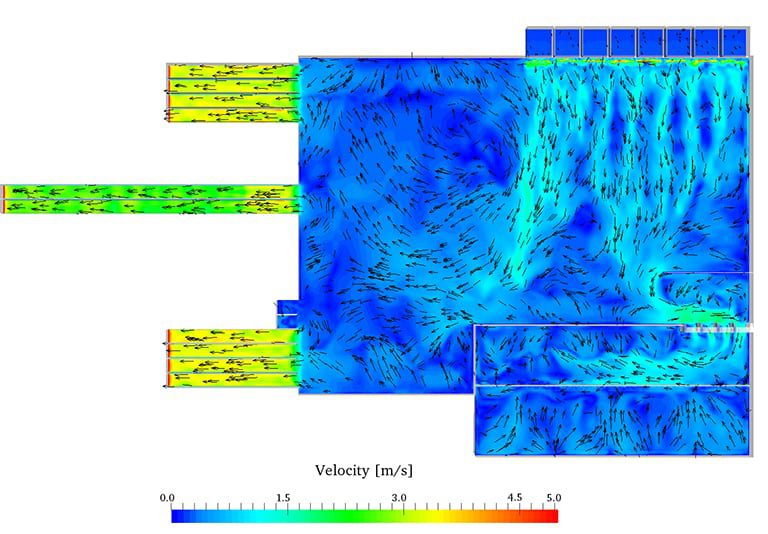

The main goal in using a CFD simulation, more precisely free-surface multiphase flow modeling, was to determine the flow topology at the outlets of the basin.

SimScale has allowed us to have a very fine knowledge not only in terms of flow type and flow regime but also flow velocities, flow distribution and turbulence phenomena that occur at the same time on the inlets and outlets of the projected water storage basin, both in the case of maximum flow operation and in the case of low flows. This allowed us to optimize the design and dimensioning of the structure and to provide the necessary equipment and facilities to put in place both in the working and the final project phase.

Fadili Tarik

CFD Engineer

Sogea Maroc’s engineering team decided to go with the SimScale cloud-based CAE platform and simulated a pre-filled basin configuration with multiple inlets and several free and suction outlets. In order to be able to assess the free-surface contour at different times, showing the water level and the height with reference to the basin floor, Fadili Ham, CFD engineer at Sogea Maroc, ran a multiphase analysis.

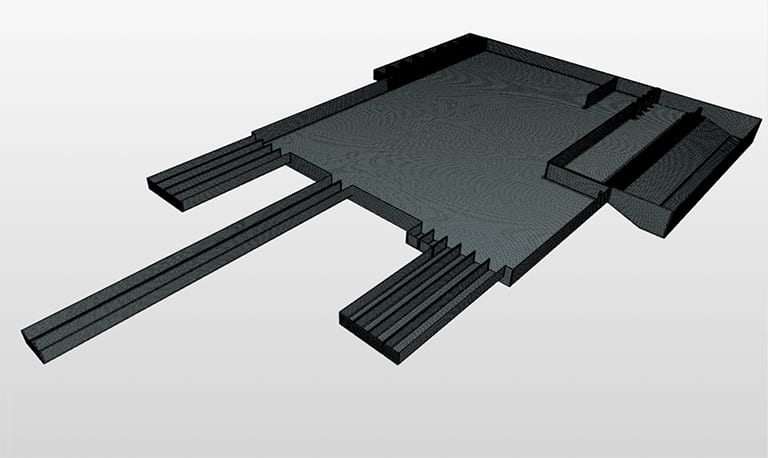

After being uploaded onto the platform, the CAD was meshed using the hex-parametric algorithm with different types of refinement. The result was a 3-million elements mesh as seen above.

“With the SimScale hydraulic model, we were able to highlight our technical solution and satisfy our customer. Thus, we were able to optimize the cost of carrying out the project,” mentioned Fadili Tarik.

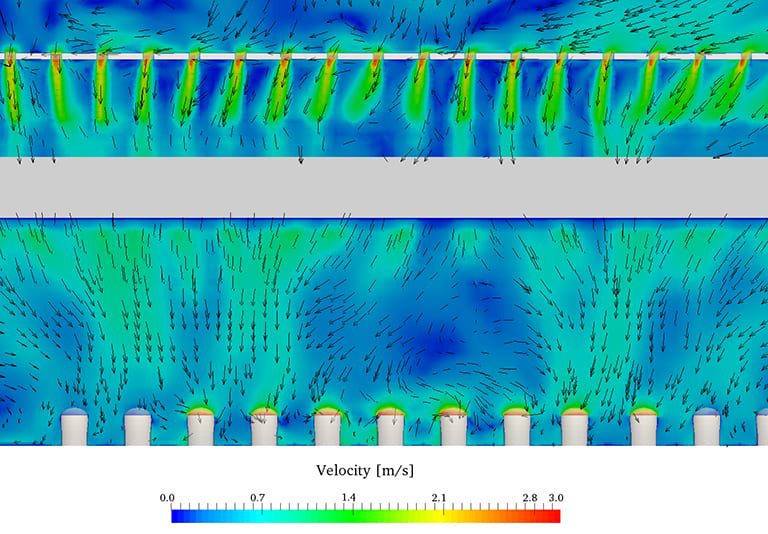

The CFD simulations performed in the cloud with SimScale gave Sogea Maroc’s team valuable insights into the performance of the facility basin. The results shown the flow topology, velocity magnitude, and direction of the flow as it moves within the facility basin.

Recirculation regions could be observed around the suction pipes. Fadili could then assess that these recirculations were present as some of the pumps were not operational during the analysis. Hence the flow was sucked and recirculation regions were formed.

In the end, the simulation results were able to show that for the given flow conditions, no overflow of the basin would happen and the water level drop from the initial pre-filled height would be under control and would not cause operational problems.

Sign up for SimScale

and start simulating now