Smartlouvre Technology Ltd. (Smartlouvre) are manufacturers of high-quality louvred metal fabrics. Their MicroLouvre™ solar shading screens are the result of decades of extensive and exhaustive international research and development. They are probably the most efficient modern method of solar shading in the world. Smartlouvre is focused on the construction specification market, working with architects, building consultants, and engineers on improving building performance and energy consumption in controlled temperature environments.

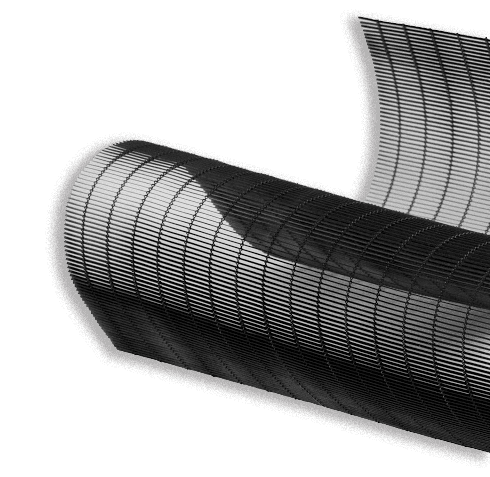

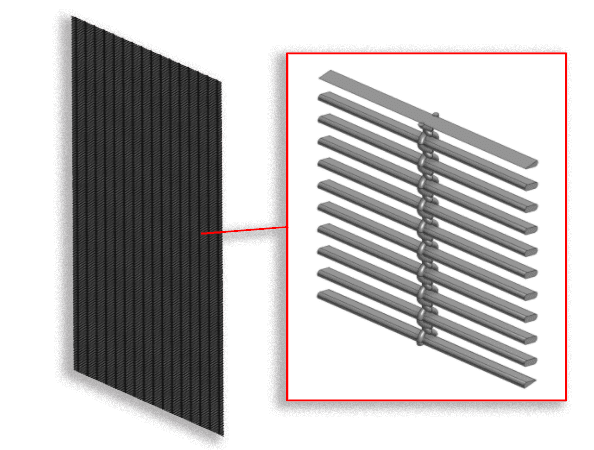

The Smartlouvre MicroLouvre™ is a woven fabric /mesh of paper-thin bronze louvres used to enhance the performance of any glazing or building facade. It is commonly attached to external windows and acts as a natural ventilation and solar shading device. The metal fabric has exceptional performance properties. Its glare control capabilities and strength, combined with its lightweight property, fire, and heat resistance, make it uniquely versatile. It has been used in limitless shapes, sizes, and colors for all types of window coverings, lighting design and control, exhibition displays, and for managing natural ventilation and solar gains in buildings.

There is no other product like MicroLouvre fabric. It is totally unique with a wider combination of thermal, environmental, and comfort performance characteristics. Due to the many variables which underpin the overall performance of MicroLouvre Screens, it is necessary to be able to correctly replicate its performance in building modelling and simulation studies. Building simulation is used widely in the construction industry to design, specify, and approve in accordance with building regulation standards. Building simulation tools are used by architects, engineers, and sustainability consultants to optimize the energy and environmental performance of a building design, and in turn use this as evidence to pass through the planning and approvals process. Only then can a new building or refurbishment/refit go ahead as planned.

Previously, the building simulation community was not aware of how to model the multiple performance characteristics of Smartlouvre’s MicroLouvre Screen. This meant that it was difficult to incorporate MicroLouvre Screens into building designs as well as include it within standard specifications. Extensive testing at Fraunhofer ISE and LBNL California was commissioned to verify its performance for certain aspects like solar shading and thermal performance. These data sets, which proved the high performance of MicroLouvre were then made available, but not in a form needed for building design.

The project with SimScale was completed in several stages:

Smartlouvre decided to recruit the expertise of SimScale GmbH because SimScale recognized the unique nature of the product and the fact that its performance was complex and challenging to simulate. SimScale's expertise in the architecture, engineering, and construction sector meant they had a clear appreciation of all the challenges with simulating MicroLouvre performance criteria.

Andrew Cooper

Managing Director at Smartlouvre Technology Ltd.

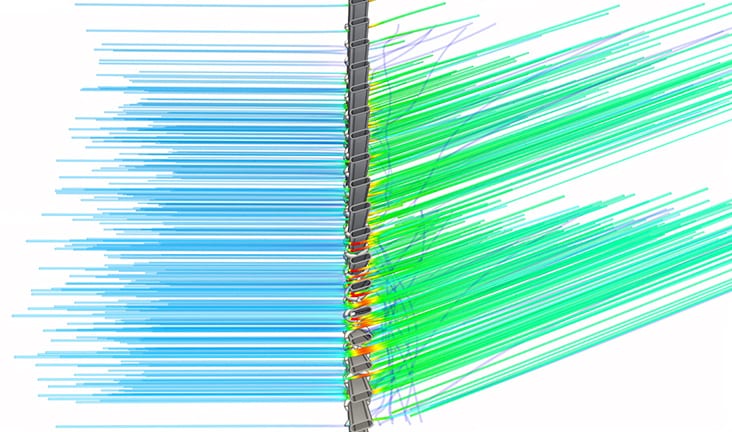

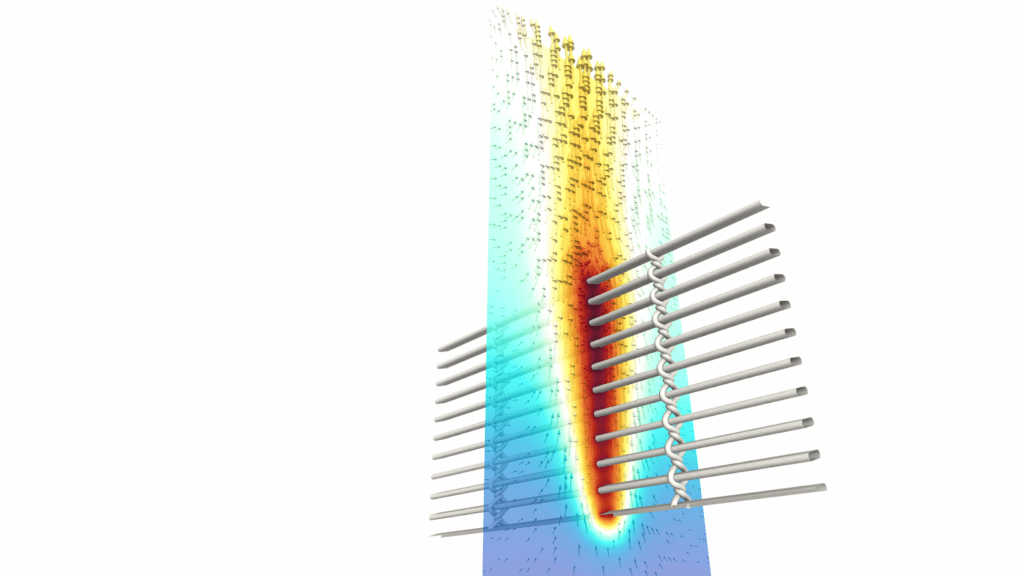

The results from SimScale illustrated to Smartlouvre useful performance characteristics of a MicroLouvre Screen. Its aerodynamic behavior could be visualized, and SimScale was able to assess the pressure-flow characteristics at various wind speeds, flow rates, and wind directions. This insight is useful for understanding the current performance of MicroLouvre, but also allowing a parametric design analysis to further enhance its overall performance by altering louvre angle, thickness, material, etc.

SimScale also showed how the air would enter a room, as the louvre angle was pitched at 17° thereby altering the flow of air. This attenuation is dependent on wind speed and local conditions, and serves to improve the efficacy of the air mixing in the room.

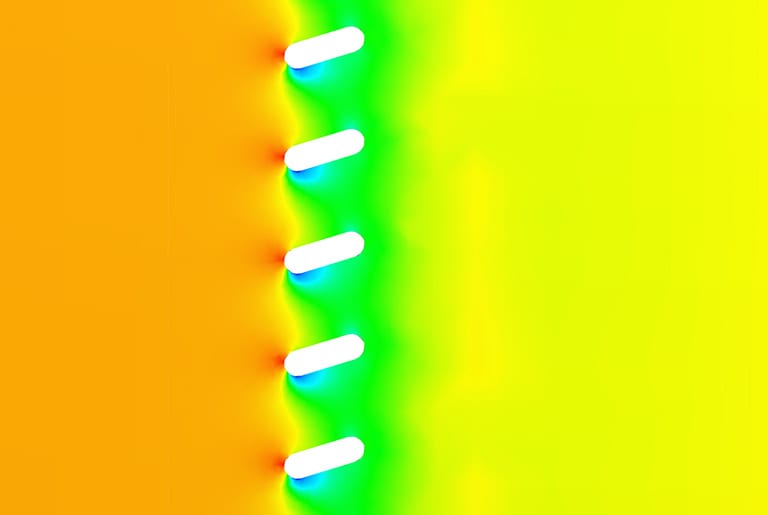

The geometry of a MicroLouvre Screen is complex and very fine. The louvres themselves are only 1.5 mm wide, meaning a 3D model accurately representing the build of the system is a very large file. This becomes prohibitive if engineers try to physically model MicroLouvre in CFD, as the meshing and computational requirements become restrictive. SimScale used the Darcy-Forchheimer model to determine appropriate coefficients and unit vectors to be able to model the complex flow behavior of MicroLouvre using a porous media simplification. The comparison between physically modelling MicroLouvre and using the porous media simplification is almost a 100% match.

Due to the fact that MicroLouvre is a metal fabric made of 90% copper alloy, its thermal conductivity is high. In still or low wind speed conditions a ‘chimney effect’ can be observed where the metal fabric is much warmer (due to incident solar and reflected gains) than the surrounding air, causing air to rise like a column above a MicroLouvre Screen. In certain double-skinned facade systems, this might be a useful property. This observation was also useful to determine a minimum MicroLouvre Screen-Window distance to minimize any unwanted heat gains into a space.

SimScale and Smartlouvre conducted some scenario analyses in various types of buildings to assess the installed impact of MicroLouvre on thermal comfort and energy efficiency. For a three-story healthcare building with typical internal gains, a London climate and thermal performance meeting minimum Part L (Conservation of Fuel and Power 2013) regulations, the following was observed:

Smartlouvre now has two methods to model MicroLouvre Screens in building simulation models for solar shading and the relevant data to represent its performance in natural ventilation models. They are now confident that the construction industry can integrate the unique MicroLouvre system in their building designs and refit plans.

Sign up for SimScale

and start simulating now