The team at Raycore Lights had been developing a new product for overhead lighting applications. Though they already had a pretty good idea of the prototype process based on their existing products, the team wanted to ultimately shorten the design and prototype lifecycle.

Being familiar with CAE products available on the market, Raycore wanted to incorporate a CAE tool that would add value but not pose a high financial barrier. For previous products, Raycore Lights had contracted some of the thermal analysis needed to an outside company, because they did not have the necessary resources at the time.

In this past case, the solution that the team ended up with met their design criteria but was costly in financial resources and time. Because of this experience, Raycore set out to find a new CAE tool that would allow them to have full control of the design process while also controlling cost. They came across SimScale from searching for a suitable option online that fit their criteria.

For the team at Raycore, the main consideration was cost. Commercial FEA and fluid dynamics software are typically very expensive and require large overhead and hardware investments required to operate them. SimScale’s subscription-based simulation software solution provided access on more of an as-needed basis and met the needs of the Raycore team.

SimScale provides businesses the opportunity to access high-end resources that would typically only be available to well-established companies. The subscription service/cloud computing approach has allowed us to improve our design process and the end products that we provide to our customers without overextending financially, a big win for us!

Mark Williams

VP Operations and Engineering

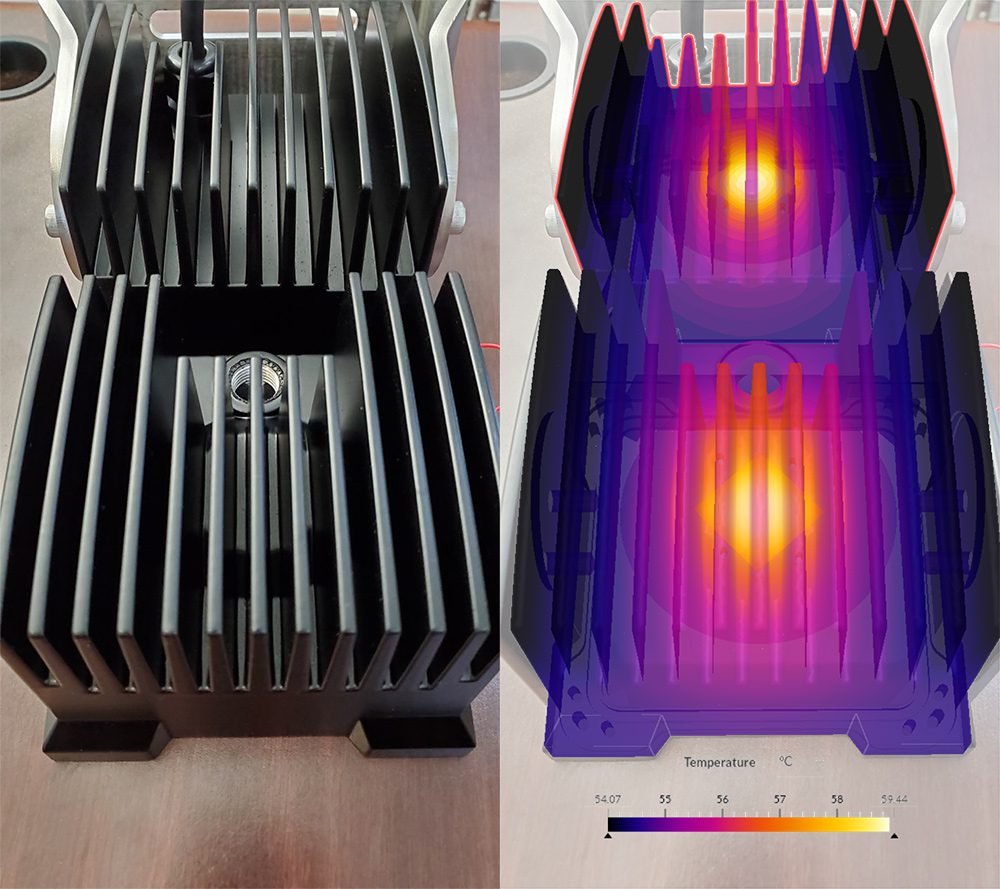

The team started by performing simple thermal analysis, setting up multiple spreadsheets to calculate the heat transfer coefficient for some of their existing products, and then used that coefficient to validate empirical results. The first couple of validation analyses went very well and the results were solid.

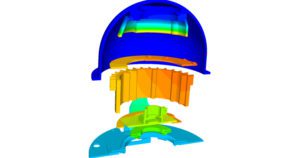

When Mark and the team proceeded to do an analysis on the new product, they realized that they had been making a lot of assumptions due to the drastic changes in geometry. Several application engineers at SimScale jumped on the project and provided support, so that Raycore could set up a CHT analysis of the new product which effectively calculated the heat transfer coefficient, eliminating many of the assumptions that were previously made.

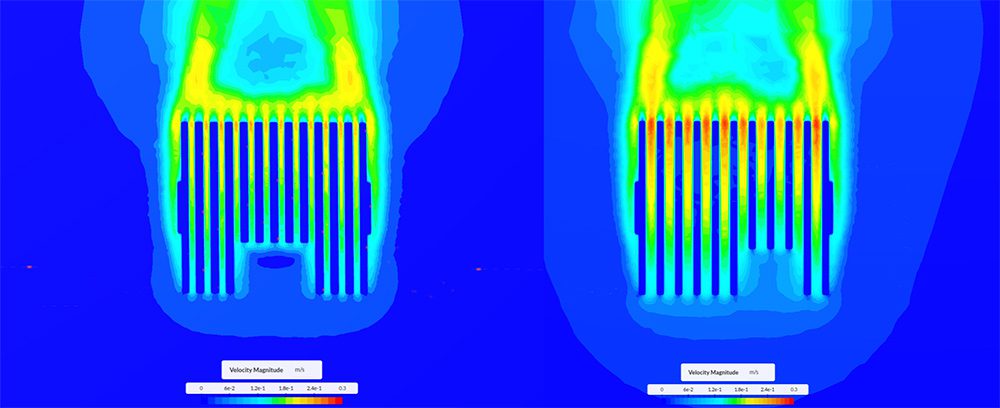

For this project, Raycore was in the prototype phase, so finding a geometry that maximized heat transfer while minimizing weight was most important. They began by creating a generic heatsink in their CAD software, which was parametric and could be quickly updated.

They began with a higher quantity of fins based on hand calculations, and presumptions of what the fin count should be. They then created a series of models that reduced the number of fins on the heat sink by a few at a time. Once they had a thermal model that provided good results, they were able to queue up multiple thermal models for each of the iterations produced in CAD. The beauty of this approach is that the team was able to run them all at the same time. Each analysis took about five hours to complete, instead of tying up local resources for 80 hours, and they were able to run all simulations in the same time it would take to complete one simulation. After the simulation runs were finished, they could simply review the results and choose the analysis that provided the results that met the design criteria.

Within the SimScale platform, the team used the following features:

After Raycore Lights homed in on a working solution for their design, the simulations ran smoothly. They required a couple of additional refinement regions that the team was not previously using as well as a column to help initialize the flow direction. Mark and his team ran seven or eight simulations, each simulation lasting about five hours, and about 450 core hours in total.

The team assumed that the simulation results wouldn’t be a 100% match with the empirical results, but were interested in finding out how the geometry changes would affect each iteration. They found that being able to copy the mesh settings and substitute geometry from one analysis to another was very helpful and time-saving.

On previous projects, Raycore normally went through about five different geometry iterations until arriving at a production model, with not all of those changes being directly related to the thermal performance of the housing. In terms of ROI for this project, the team estimates that SimScale will help limit the physical prototyping needed, therefore saving money.

Since this project, the team has continued using SimScale on an existing product that they are planning to rework. Raycore Lights will continue to iterate on existing projects that already boast good performance while testing new manufacturing techniques to improve performance even further while reducing product weight. Here at SimScale, we look forward to continued collaboration with Raycore Lights!

Sign up for SimScale

and start simulating now