Power Maxed Racing (PMR) is a motorsport engineering team specializing in vehicle engineering, suspension dynamics, and motorsport management. This core expertise has enabled Power Maxed Racing to win multiple races and titles in the last five years. Whether road, track, or race car, from basic setup to fully built race winners, PMR’s experienced team have diverse skills from racing drivers, engineers, management, and now simulation. PMR has designed, built, and successfully campaigned numerous cars in multiple championships. The design and build of the current next-generation touring car (NGTC) technical specification from the British Touring Car Championship (BTCC) Vauxhall Astras were all carried out under the roof of PMR’s Warwickshire-based Race Shop in the UK.

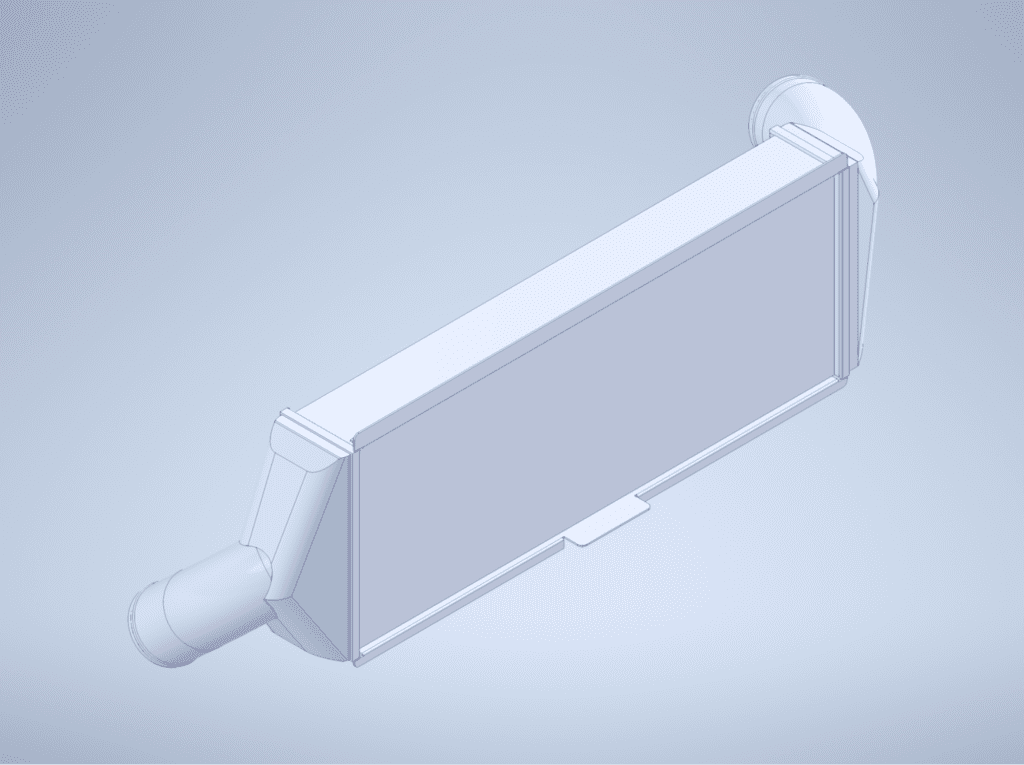

Dan Rathmill has worked at Power Maxed Racing for over six years as a design engineer, designing components for the next-generation Vauxhall Astra touring car used in the championships. Utilizing the latest CAD and simulation software, including SimScale, the highly experienced design team works alongside clients to ensure that not only does their idea take shape as a competitive chassis but that everything around it, from suspension to air ducting, is digitally verified before moving to prototype and production. PMR uses cloud-native engineering simulation to design & develop specialist cooling systems, including radiators & intercoolers, maximizing the intake temperatures & airflow using computational fluid dynamics (CFD) and then verifying the performance of these components before costly in-house fabrication.

Dan, a mechanical engineer, is the simulation specialist at PMR. PMR had legacy CFD software for many years and needed help with its rigid license type, lack of collaboration tools, and the fact that the software was fixed onto one computer. SimScale offered similar simulation features without the upfront capital cost of software and the need for expensive hardware. As a cloud-native engineering simulation tool, SimScale is accessible on any device by a simple login on a web browser. This makes it far easier for a touring team like PMR to have access to simulation continuously. The licensing can be scaled faster than desktop software, and additional users and product updates are as simple as one click.

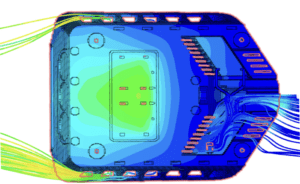

Before using simulation, PMR designed parts for their high-performing race cars but could only predict performance once they got to the prototype stage. Often, they would make many prototypes of the most likely design candidates, based on their experience, who were likely to succeed. PMR uses SimScale to model internal flows through radiators and intercoolers to maximize the air-cooled race car. Many aspects of the touring vehicle are fixed and, according to strict BTCC guidelines, cannot be altered. This means PMR must be extra creative in solving problems with high constraints, such as the design of the air intake to intercooler ducting and the flow of incoming air over the radiators. This is the current project Dan and his team is working on at the moment to optimize the design and development of cooling components for next year’s racing season. The simulation stage is critical to verifying the performance of their parts before they move on to costly 3D prototyping and manufacturing. Using SimScale, the potential number of component design candidates that will be prototyped drops from 5 to 1-2, significantly reducing costs. Ensuring PMR uses the radiators’ total capacity by encouraging incoming air to flow over a wider heat exchanger surface area will provide more cooling capacity and uniform distribution of cooling over the radiator. The water-air radiator can perform at a higher efficiency leading to better-performing engines and cars.

In motorsport timing is critical and simulation saves time.

Dan Rathmill

Design Engineer at PMR

Using the Autodesk Inventor to SimScale workflow, the ducts from the air intake to the intercooler needed improving to optimize airflow over the radiators. The air enters from the front of the car bumper openings, through the ducting, and into the intercooler. PMR evaluated multiple duct designs to guide the air more uniformly by adding different configurations of guide vanes. Key insights from the simulation include flow rate, spread, and uniformity & temperature distribution. The intercooler is far from the bumper air intake and the duct takes a steep incline and a bend to get to it. Flow detachment is of concern.

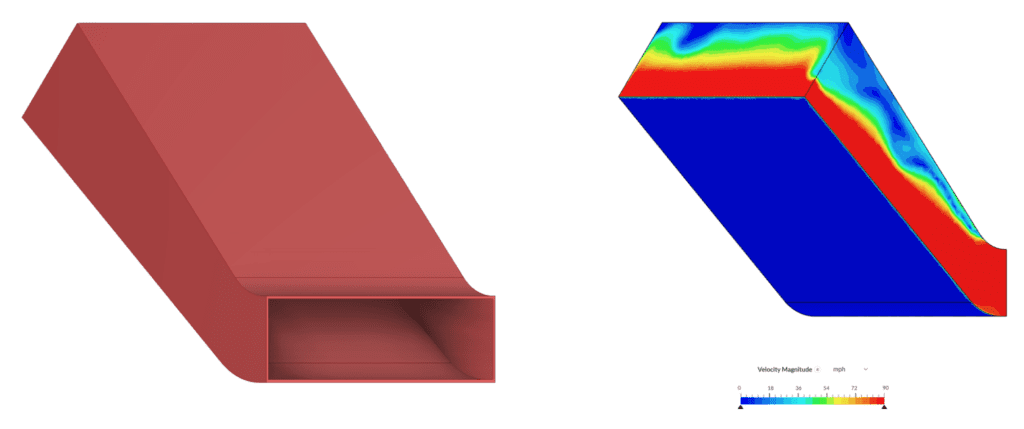

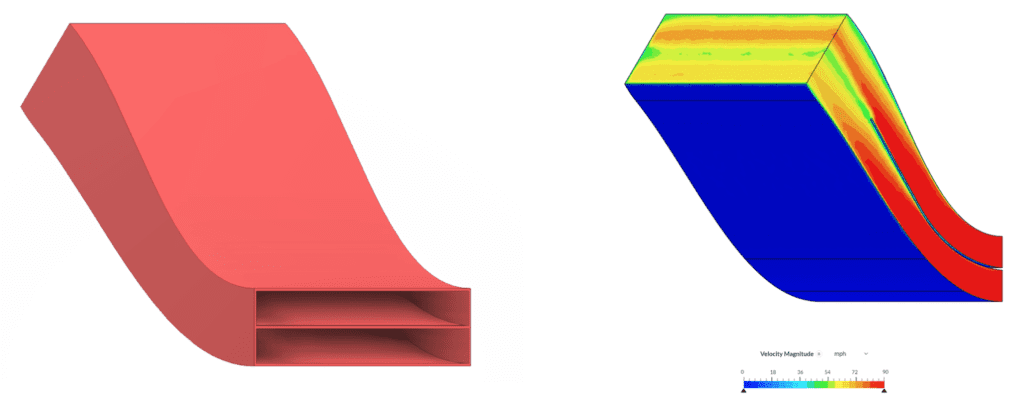

The images below show the original duct design, which gives a non-uniform and turbulent airflow toward the top of the duct where the intercooler sits. The duct exit face is approximately 550×200 mm, which meets flush with the face of the intercooler. The duct depth is only 70 mm, and at duct intake air speeds of 90 mph, the intercooler was only managing to achieve 0-45% airflow coverage over the radiator core, which has a water/chemical mixture as the coolant.

Extensive simulations have shown that this non-uniform flow is subduing the thermal performance of the intercooler and radiators. Improved duct designs deliver a more even and less turbulent airflow through the ducts. The entire design study used the parallel simulation capabilities in SimScale to model dozens of different vane shapes, angles, and sizes inside the duct.

What it (SimScale) does give us is the opportunity to make parts in CAD, then run them in simulation, and then keep repeating this process until we are happy to go forwards and make the actual prototype before going to the racetrack to test our developments.

Dan Rathmill

Design Engineer at PMR

PMR heavily focuses on applying CFD to optimize its current race car for the next racing season (2023). Component upgrades during a live racing season are standard; timing is especially critical in these situations. The team has little capacity to test new components in the car in between races, which is when the advantage of virtually verifying the performance of components using SimScale is essential. The team will expand on using FEA in SimScale to evaluate critical components’ structural integrity and longevity.

Sign up for SimScale

and start simulating now