PHIX offers assembly services and contract manufacturing for photonic integrated circuits (PICs) and MEMS. They build optoelectronic modules based on all major PIC technology platforms, such as Indium Phosphide, Silicon Photonics, Silicon Nitride, and Planar Lightwave Circuits, specializing in chip-to-chip hybrid integration, coupling to fiber arrays, and interfacing of DC and RF electrical signals. By offering their expert knowledge already at the chip design stage, they can ensure ease of scale-up for volume manufacturing. PHIX uses engineering simulation to optimize the design performance of its electrical devices using heat transfer simulation and computational fluid dynamics (CFD).

Photonic integrated circuits (PICs), or application-specific photonic integrated circuits (ASPICs), are advanced data and energy transmission devices utilizing photonics. They surpass traditional electronic ICs in miniaturization, processing speed, and power efficiency. PICs find extensive applications in diverse domains such as LIDAR in autonomous vehicles, medical imaging, and quantum computing. Despite their compact functionality, PICs require integration into photonics-enabled modules for operational utility. This necessitates connections to optical fibers, additional PICs, cooling systems, and electronic components. PHIX specializes in the design and fabrication of these packages, a process distinct from conventional semiconductor packaging. This involves intricate micro-assembly to incorporate thermal management, optical fiber, and electronic connections, resulting in modules with both optical and electrical interfaces.

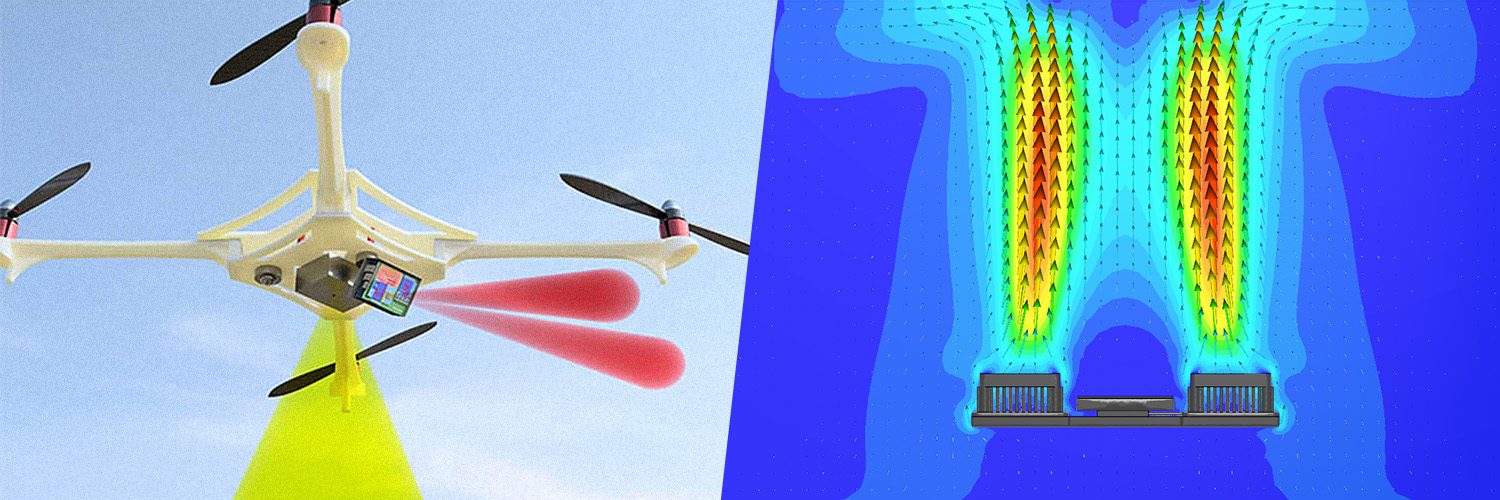

The TERAWAY European H2020 5GPPP Phase III project, in which PHIX collaborates with a consortium of 12 partners from six EU countries, aims to revolutionize transceiver modules using integrated photonics. The project aspires to develop prototypes for ultra-high-frequency (near 322 GHz) wireless data transmission, targeting speeds up to 241 Gb/s and ranges over 400 meters in the THz band. A notable application is the deployment of these transceivers on UAV drones for high-bandwidth communication and crowd monitoring in large outdoor events.

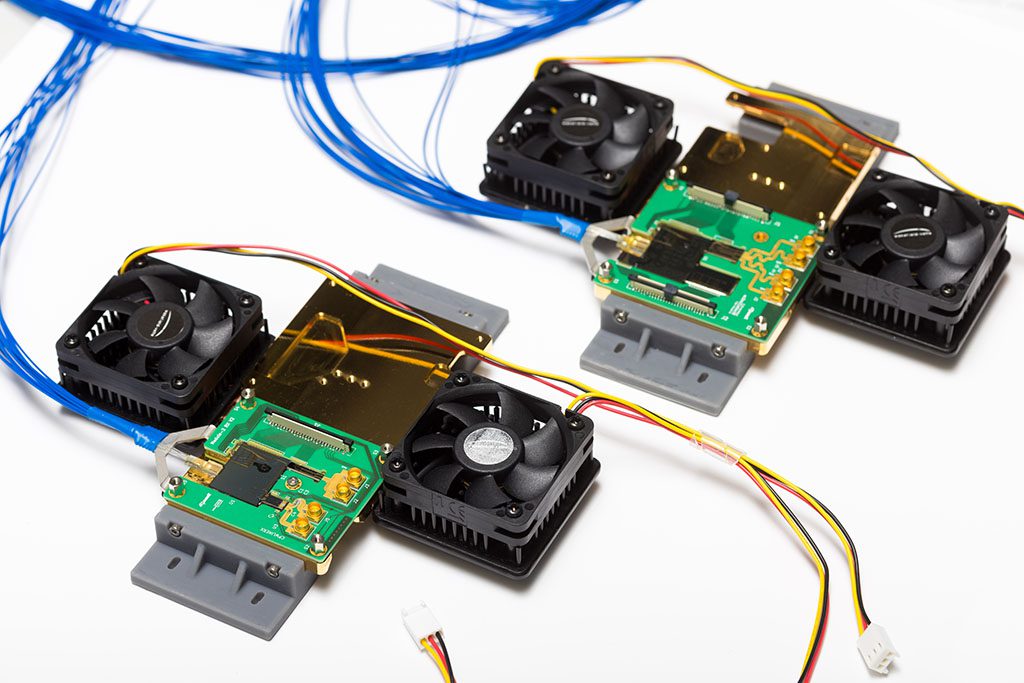

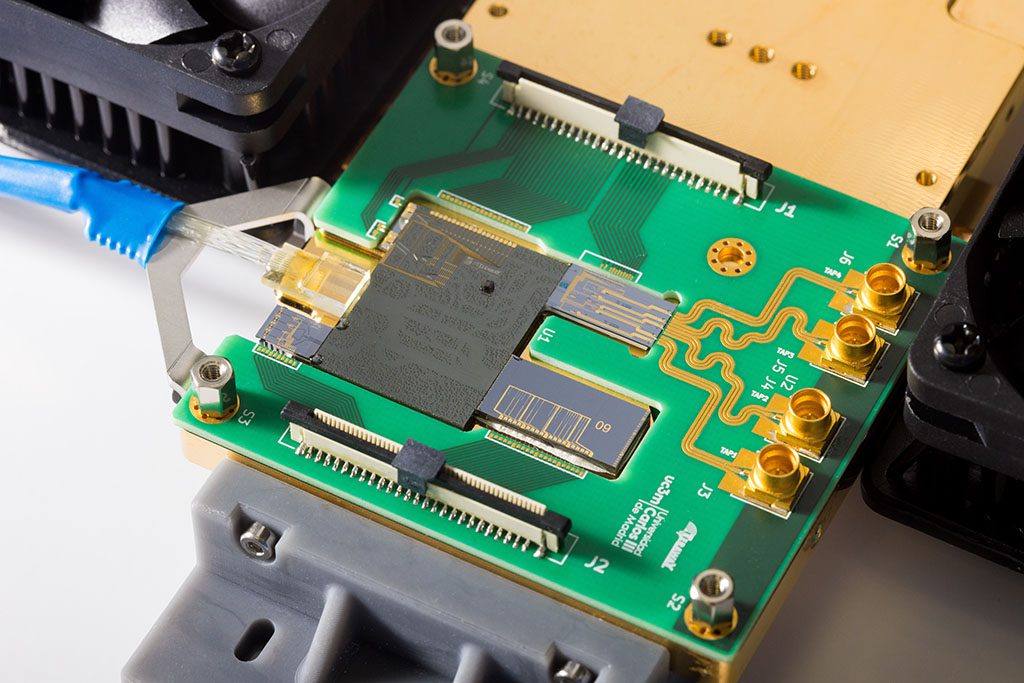

PHIX’s role in TERAWAY focuses on addressing the hybrid integration of diverse photonic components, terahertz antenna integration, and thermal management. The THz transceiver includes both a transmitter and a receiver, utilizing a ‘photonic motherboard’ concept for chip integration. This complex process involves accommodating various technical and practical constraints, like temperature resilience and handling fragile components, such as long silicon antenna rods.

A significant challenge in the project is the thermal management of components with varying heat sensitivities and emissions. For the drone-mounted PICs, the densely integrated design makes it hard to avoid placing thermally sensitive components, in proximity to components generating a lot of heat, like the drivers for phase modulators. Solutions like Peltier thermoelectric coolers (TECs) and copper heat pipes are being explored to address these issues. PHIX’s contribution centers on the intricate packaging of these transceivers, encompassing hybrid photonic integration, precision in attaching silicon antenna rods, and optimizing thermal management strategies within the confined space of the module.

It was my first time using SimScale. I found the customer support was excellent, the software itself was easy to use with a highly intuitive interface. In the European-funded projects, the simulations are helping identify issues with the design before they go into the production stage, which gives a better result in the end!

Nienke Nijenhuis

Engineer at Phix

With such a complex design landscape, ensuring that every component operates optimally is paramount. Enter SimScale, the advanced simulation tool chosen by PHIX for this mission. Nienke Nijenhuis, representing PHIX, harnessed SimScale to its fullest, conducting comprehensive heat transfer simulations on the PIC devices, structural evaluations for stress dynamics, and deformations analysis. The fluid dynamics aspect was also addressed with simulations on SimScale. Using the combination of their own computational data, coupled with supplier data sheets, the precise operating points of the Peltier devices were determined and integrated into SimScale. This was considered a valid approximation to mimic the performance of a Peltier device.

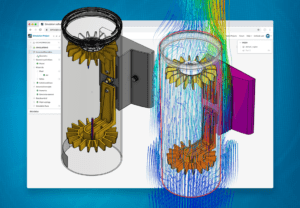

The entire design is verified in a conjugate heat transfer simulation using SimScale. This enables engineers to check if previous assumptions were valid and also to see the effect of, for instance, running the system without forced convection on the heat sinks. It should be noted that in this type of simulation, the TEC cannot be efficiently modeled directly. Instead, it is approximated by internal boundary conditions of fixed temperature and heat flow. The results indicate that leaving the fans off will result in significant overheating of the system due to the large increase in thermal resistance to the ambient environment. However, when the fans are run, we see the system behaving well. In particular, the hot side of the TEC is approximately 48° C, which compares well to the expected value of 43.5° C from the previous calculations.

The outcomes were insightful and revealed the risks associated with passive cooling, indicating the system’s susceptibility to overheating. Various cooling strategies were investigated including different types of heat sinks, natural ventilation, fans, Peltier cooling devices, and heat pipes. However, with the fans active, the system showcased optimal performance, mirroring the expected outcomes derived from initial calculations.

We use SimScale to find solutions in system design, often looking at thermal management of electronic devices. In the Teraway project, for example, we were able to select the correct thermal management system at a much earlier stage of design because of SimScale. Using simulation, we were able to test things that weren’t considered possible, e.g. liquid cooling systems, and thus had a broader cooling solution space to choose from. SimScale helps us with feasibility studies early on which has enormous impacts on the whole project.

Nienke Nijenhuis

Engineer at Phix

Sign up for SimScale

and start simulating now