Driven by the power of uncompromising innovation, Paris HVAC is a young dynamic company providing expertise in designing and improving HVAC systems. They are based in Paris center, and operate only in the Paris region. Their clients are professional HVAC installers, HVAC maintenance specialists, architects, manufacturers, and contractors.

Currently a one-man-operation, Paris HVAC owner and founder Benoît Mallet began using SimScale in 2018 when he found himself with an interesting case at hand. Benoît, an expert in all things HVAC, had the challenge of ensuring safety standards could be maintained in a particular kind of laboratory room housing an exhaust cupboard.

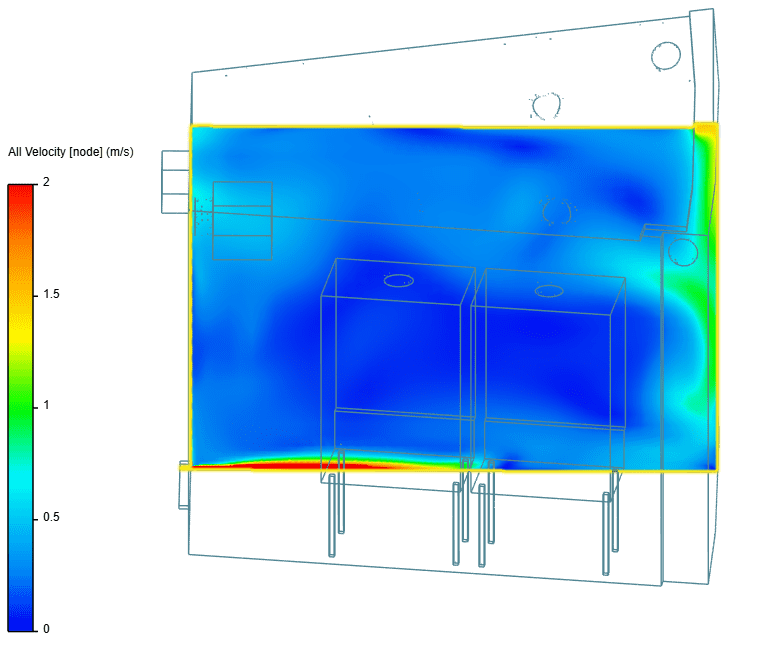

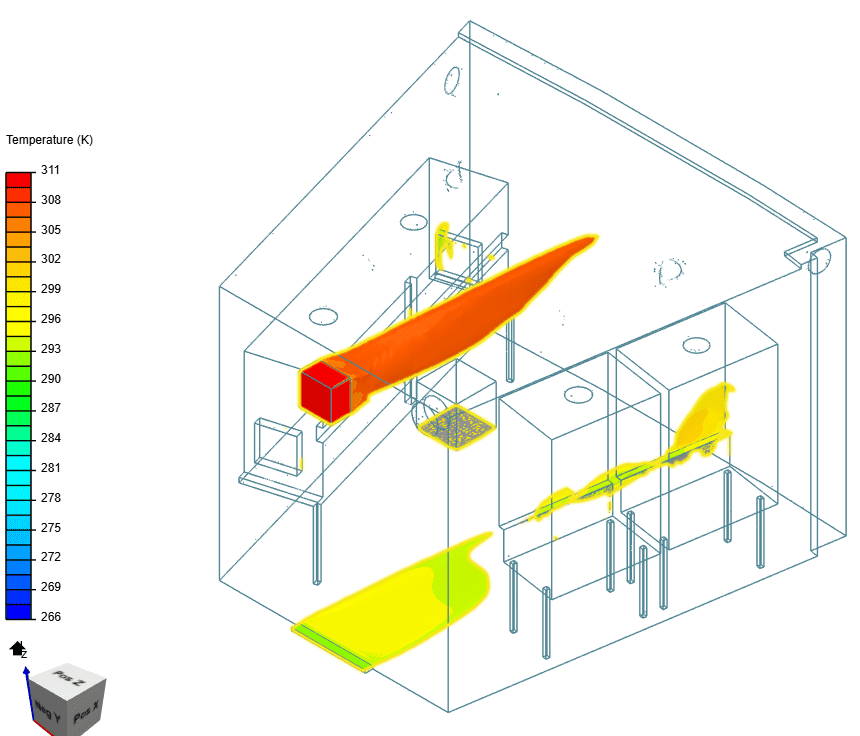

The nature of the room was to test and validate products involving dangerous chemicals that could be hazardous if inhaled, therefore ensuring proper ventilation of the fumes was imperative. The project, and ultimately, the HVAC unit devised needed to account for a variety of use cases while guaranteeing a constant low negative pressure within the fume hood itself. More challenging still, turbulence near the entry of the fume hood needed to be minimized in order to avoid a dangerous backwash of harmful fumes.

Before CAE and simulation, the methodology used to test a case like this would be through recreating the environment, prototyping, and using simulated smoke trails through tangible resources. Yet, this method can be chastised for using too many resources unnecessarily, as well as being too time-consuming in some cases; i.e., a one-off project such as this.

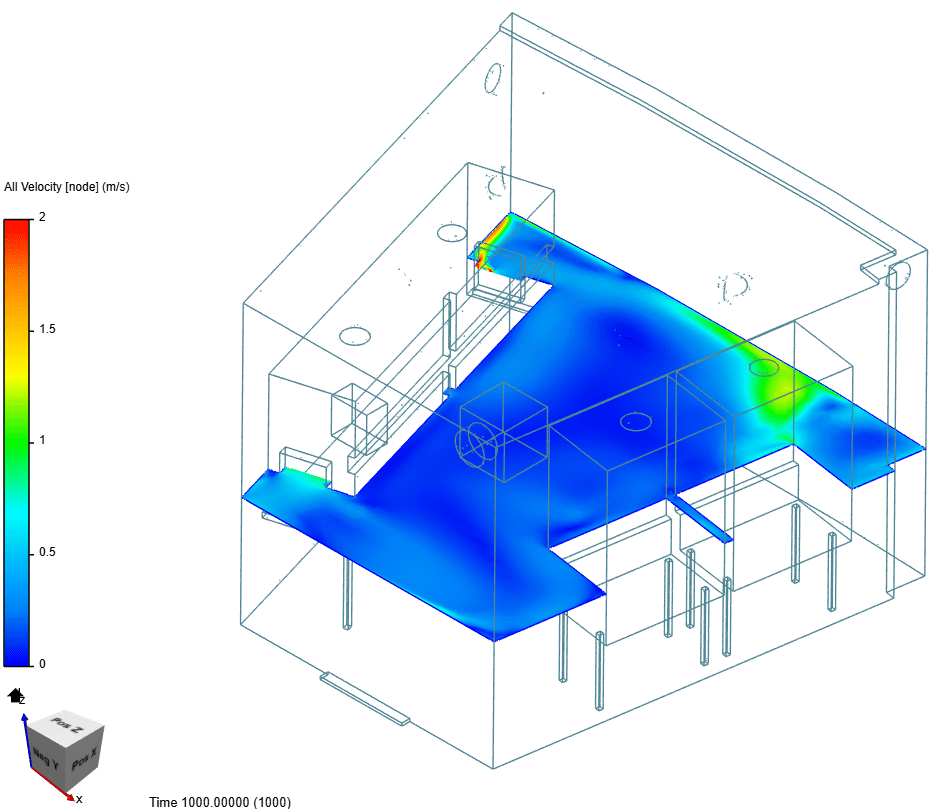

Based on the nature of the assignment, Benoît turned to CAE evaluation to assess all the different air patterns and velocities possible within the respective space. This was especially important, as 0.2 m/s velocity needed to be achieved in any scenario, and if there was too much turbulence or backflows present then the confinement of the fumes would not be achieved.

By considering three different design iterations, Paris HVAC was able to produce the ideal design that ensures lab safety while minimizing associated power costs year on year.

In order to obtain the desired results, Benoît ran convective heat transfer simulations with the incompressible flow. Nearly 1500 core hours were expended across 96 cores over the course of 14 separate simulations run in parallel. In total, Benoît can account for about 73 hours of setup, run time, and result analysis.

The results acquired from SimScale were well received by Benoît, and he planned his next steps as having a technical meeting to ensure the exactitude of the simulated confinement criteria. He was able to confirm to the SimScale engineering team that the simulation results were then validated in the real-life scenario. Benoît also attributed an ROI value in the ballpark of 4K EUR to these simulations when compared to physical testing along with time savings.

More recently, Benoit has been using SimScale more and more on differing HVAC projects. In one case he reported receiving results to that then allowed him to validate a solution sooner than ever possible before. SimScale looks forward to continued collaboration with Paris HVAC. jusqu’à la prochaine fois! (Until next time).

Sign up for SimScale

and start simulating now