OxTS was created in 1998 by two Oxford University graduates who spotted a market opportunity for land-based inertial navigation; from there it expanded to nearly 80 employees across two facilities. Today it is a fast-growing and innovative company which specializes in combining GNSS and INS technology into accurate positioning devices. It sells mainly to automotive companies who wish to perform vehicle dynamics and advanced driver assistance systems (ADAS) testing, which are necessary for modern Euro NCAP standards. OxTS also develops products for the mobile mapping survey market, including the rapidly developing field of LiDAR pointcloud creation.

The products which OxTS produces rely on input from antennae that have access to GPS or GLONASS signals. This requires antennae to be attached to the roof of the respective vehicle, and the position of these antennae with respect to each other and to the RT unit needs to be known to within a centimeter. Historically, these devices could be attached with magnets. However, an increasing number of vehicles have non-ferrous roofs and thereby eliminates this solution. This led to OXTS’need to develop a roof mount that could adapt to any car roof.

This was the first mechanical project that OxTS had started in a long time, while also being the first device to be situated outside of a vehicle. This led to safety and product lifespan concerns, which were difficult to address without suitable FEA software. The business already had a CAD/CAM software package to quickly create designs and move between configurations, but had no computer-aided engineering (CAE) software to simulate varrying conditions.

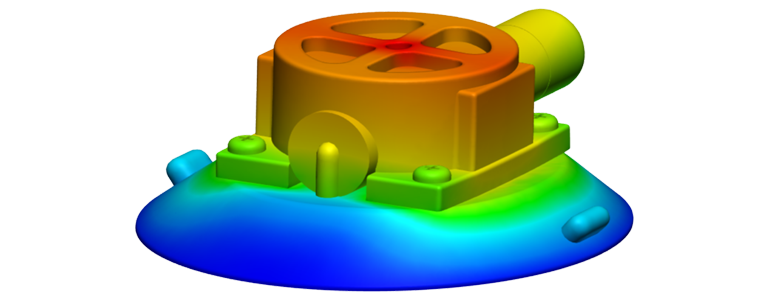

The engineers at OxTS could see a clear need for CAE: being able to reliably simulate bending forces, vibrational effects from the leg mountings, and dynamic loading. CAE would give OxTS a much higher level of confidence in this new product development, which being attached with suction cups, presented a significant risk to vehicle testers. Having spoken to a few companies, the cost of adding a built-in FEA solver was not worthwhile.

Instead, the R&D department looked for alternative packages and asked SimScale for a quotation. They replied very quickly and performed an example study to show how powerful their system could be. SimScale proved to be much more attractive for a variety of reasons:

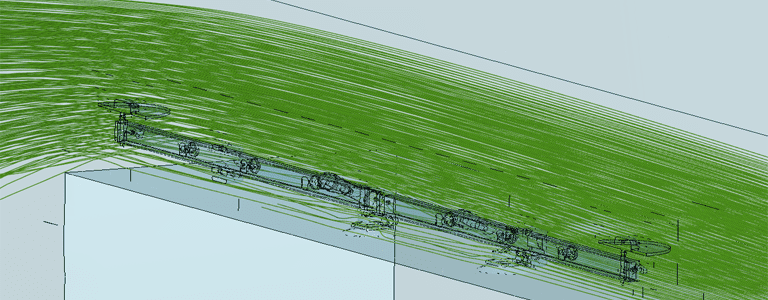

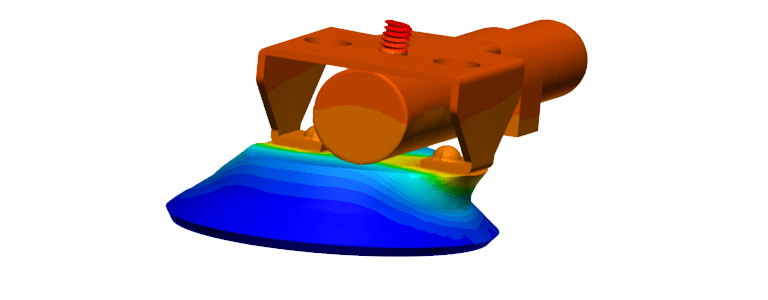

Having access to CFD was a massive bonus for the project, as the nature of the external roof mount would incur a large amount of wind effects.

The approach for simulation was to keep the design cycle in the virtual domain as much as possible. Several designs were run online through SimScale’s platform to refine the dimensions. This speeded up development time quite considerably, which was very helpful due to an optimistically-short project timeline.

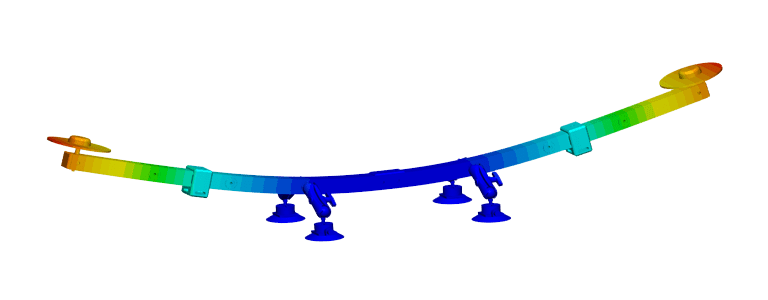

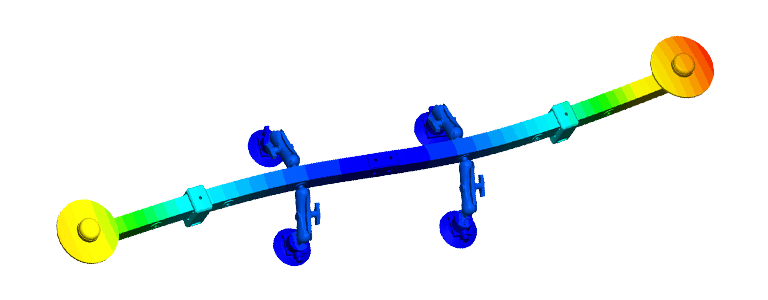

The final run completed with 64 cores in 37 minutes (39.2 core hours). The solution included an eigenfrequency plot and representations of the vibration mode shapes; all and all extremely useful for the project.

The frequency analysis was the trickiest factor to evaluate, but still made simple by SimScale support.

Michael Harris

Application Engineer

The purpose of CAE in this project was to guide the design process, as well as to verify design decisions. This was achieved on multiple occasions. In total, about 30 simulations were run, ranging from a few drag studies on air resistance to about 15 stress analysis studies to find deformation of aluminum parts.

The simulations showed expected patterns in the vibration modes, and the deflections of the bar and restraining components were shown to agree with the hand calculations.

Most of these simulations were less than 30 minutes, thanks to the number of cores allowed. Afterward, the solver fields allowed OxTS to generate computer imagery that showed the variation of deformation and stress throughout a part. This is obviously helpful for an engineer but also proved useful for explaining the project to upper management in the company.

The overall impression from the experience with SimScale was highly positive. The staff were immediately responsive and would take matters into their own hands on multiple occasions, showing their knowledge and enthusiasm.

The benefits of SimScale for the project were chiefly reduced development time and greatly reduced cost. The cost of mechanical testing was highly prohibitive for this project, quotations showing thousands of pounds for prototyping and tens of thousands for a few weeks in a test house. Investing in SimScale removed a few cycles worth of those costs from the roadmap. Future projects will benefit even more heavily from this software, since they will be able to harness simulation at an earlier stage and avoid any unnecessary reverses in the design.

“The value of having so many packages available in a single platform, which is accessible from anywhere and processed remotely by powerful servers, is incredible! The customer support makes these features stress-free and usable by anyone.”

Following the initial cost of SimScale, OxTS has probably saved on at least three physical design iterations. Considering the extra manufacturing, practical testing and loss of sales involved if it wasn’t used, the project probably wouldn’t have been possible without an affordable CAE package like this. The simulation results provide a level of verification and evidence to incorporate into the project report that is crucial from a legal perspective.

Sign up for SimScale

and start simulating now