Methanex Corporation (Methanex) is the world’s largest producer and supplier of methanol and related products. Based out of Vancouver, Canada, the business has over 1,500 employees across 11 countries and $4.5bn in annual revenue (2023). Methanex’s global operations are supported by an extensive global supply chain of terminals, storage facilities, and the world’s largest fleet of methanol-fueled tankers.

Methanol is essential to everyday life and is a recognized pathway to a low-carbon future. Whether as a key chemical building block or as a fuel—when made from renewable sources— methanol can help society achieve its decarbonization goals. It is used extensively in industrial processes, transport, and many other applications.

Methanex focuses on decarbonizing its plants using alternative fuels (biofuels) and green electricity for production. The most significant costs to a business like Methanex are natural gas feedstocks, hence the desire to move away from conventional fossil fuels. Currently, two production sites in Geismar, Louisiana, produce 2.2 million tons of methanol annually, and a third facility is under construction. Once the new plant is up and running, G3 will be capable of producing 1.8 million tons of methanol annually and have one of the lowest CO₂ emissions intensity profiles in the global methanol industry.

Monitoring had identified a fluid leakage from one of the units at the Geismar facility. Typically, this situation would have required the unit to be shut down for remediation, which would have resulted in the loss of significant production revenue. Jason Deaver, reliability supervisor for the facility, proposed to design and develop a leak containment system the same day the leak was identified. The decision was made to proceed, with Jason opting to test and optimize the performance of his proprietary design concepts within SimScale.

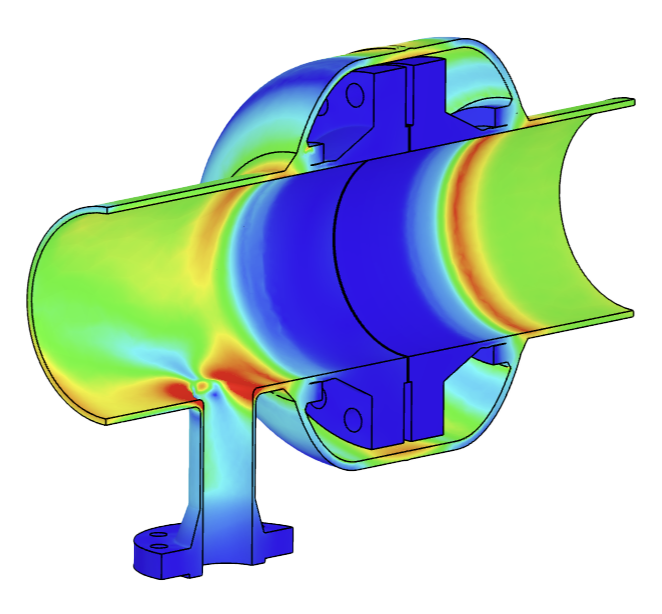

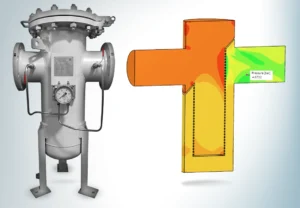

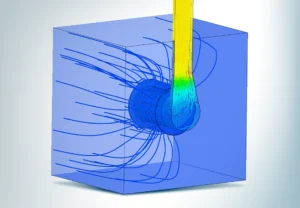

SimScale was used to assess the structural integrity of the leak containment design solution to ensure the risk of further leakage would be mitigated and the solution viable over the long term. A solution was developed and validated within an 8-hour turnaround time due to SimScale’s ease of use, breadth of capability, and rapid cloud computing. As a result, Methanex avoided a shutdown, saving the business an estimated $3.5m worth of plant downtime.

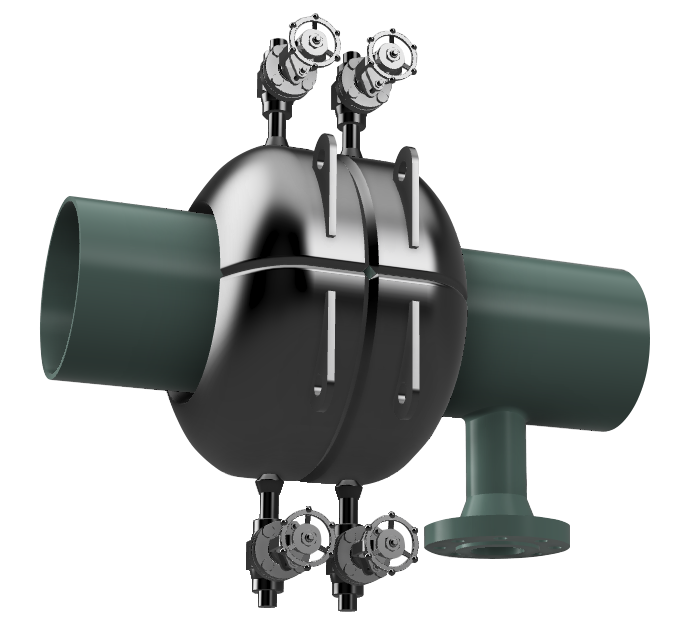

The solution shown in the images is a well enclosure clamp box to contain the leak that had developed in the weld adjacent to a flange. The leak’s location was considered extremely tricky to reach, and the plant operators could not get a traditional leak-stop services company to come out and repair the leak in the desired time.

Jason and his team were able to design a welded enclosure that excluded any gaskets. Using SimScale, the team verified the allowable structural stress for safety and plant operation, and they did this rapidly in one business day. The parallel computing capabilities in SimScale and its cloud-native features enabled this to happen without interruption.

“We have been using SimScale for FEA, CFD, and thermal analysis of our methanol production plants and components. We had a potentially high-risk situation with a leak in one of our plants and were able to use SimScale to turn around a verified solution within one business day. Without SimScale, we would have had to force an outage of the unit, costing time and significant production losses.”

Jason Deaver

Methanex Reliability Supervisor

Sign up for SimScale

and start simulating now