Luke Roberts (short LR), founded in 2014 in Vienna, is an innovative smart lighting company that combines advanced technology with modern design to improve the lighting experience in homes and offices. The Austrian team of tech and design enthusiasts introduced the “Luvo,” a Matrix LED lamp that lets users control the light’s direction and adjust brightness and color dynamically through a few taps on their iOS and Android app. This patented technology enables independent control of the lamp’s upper and lower LEDs, allowing for customizable lighting whether over a dining table, a reading couch, or for ambient relaxation. The lamp also learns the user’s lighting preferences and automatically adjusts to preferred settings for maximum convenience.

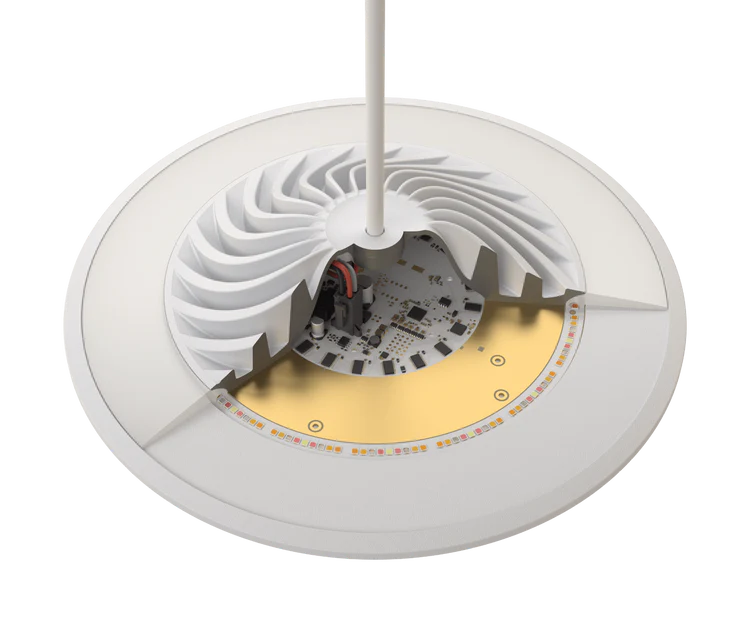

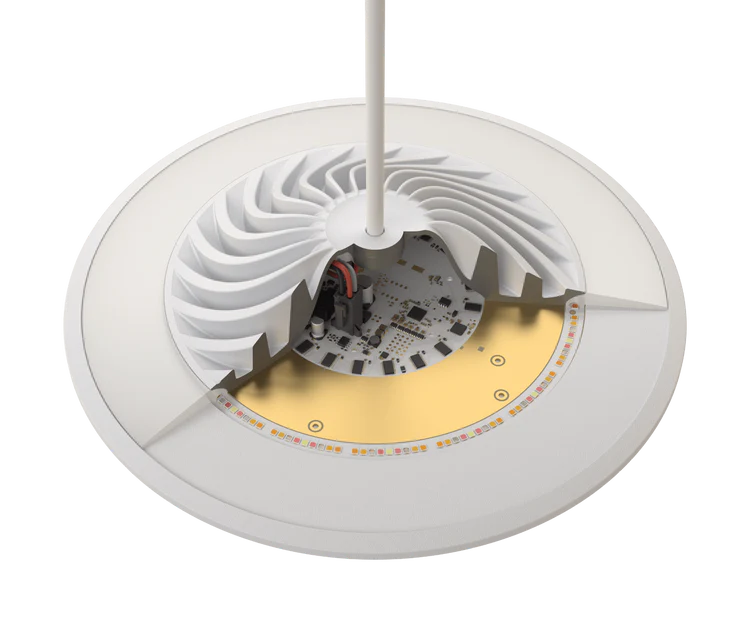

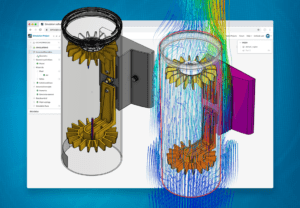

The Luvo pendant lamp was developed using a fully cloud-native design stack including Onshape and SimScale. With Luvo, users no longer just turn the light on and off. The user can decide exactly where it should shine, how bright, warm, or colorful. This brings ultimate flexibility to lighting and the right light for every mood and space. The Luvo lamp’s main function is a smart LED lamp with over 300 multi-colored LEDs giving 4400 lumens at a color temperature of 2700 – 4000 Kelvin that directs light in any direction.

One of the best features of SimScale is the ability to quickly import Onshape CAD geometry. We now have a fully cloud-based design software stack that has increased our R&D engineering efficiency and workflow.

Omid Javanmardi

Design Engineer at Luke Roberts Lighting

By leveraging advanced simulation tools like SimScale, LR can evaluate potential improvements in LED performance and longevity through optimized heat sink designs, emphasizing the importance of effective thermal management in LED lamps.

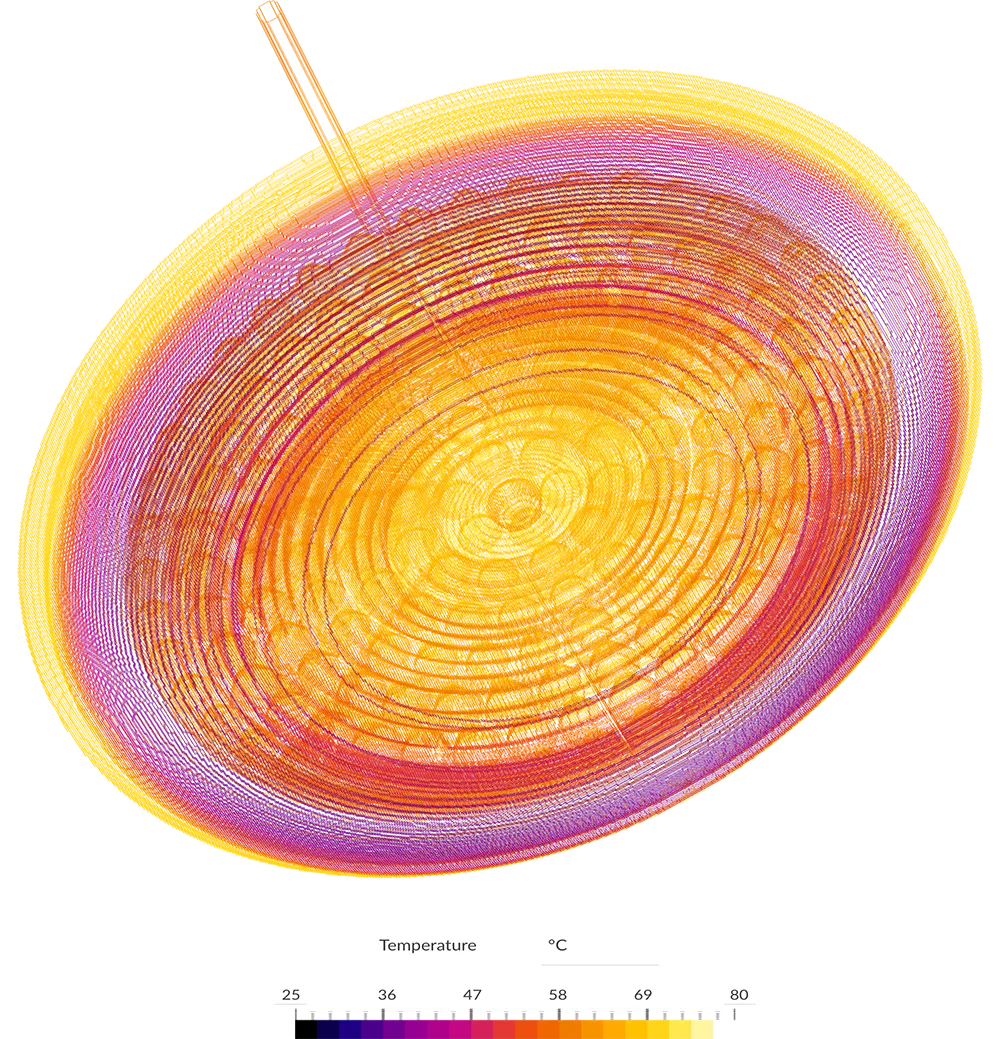

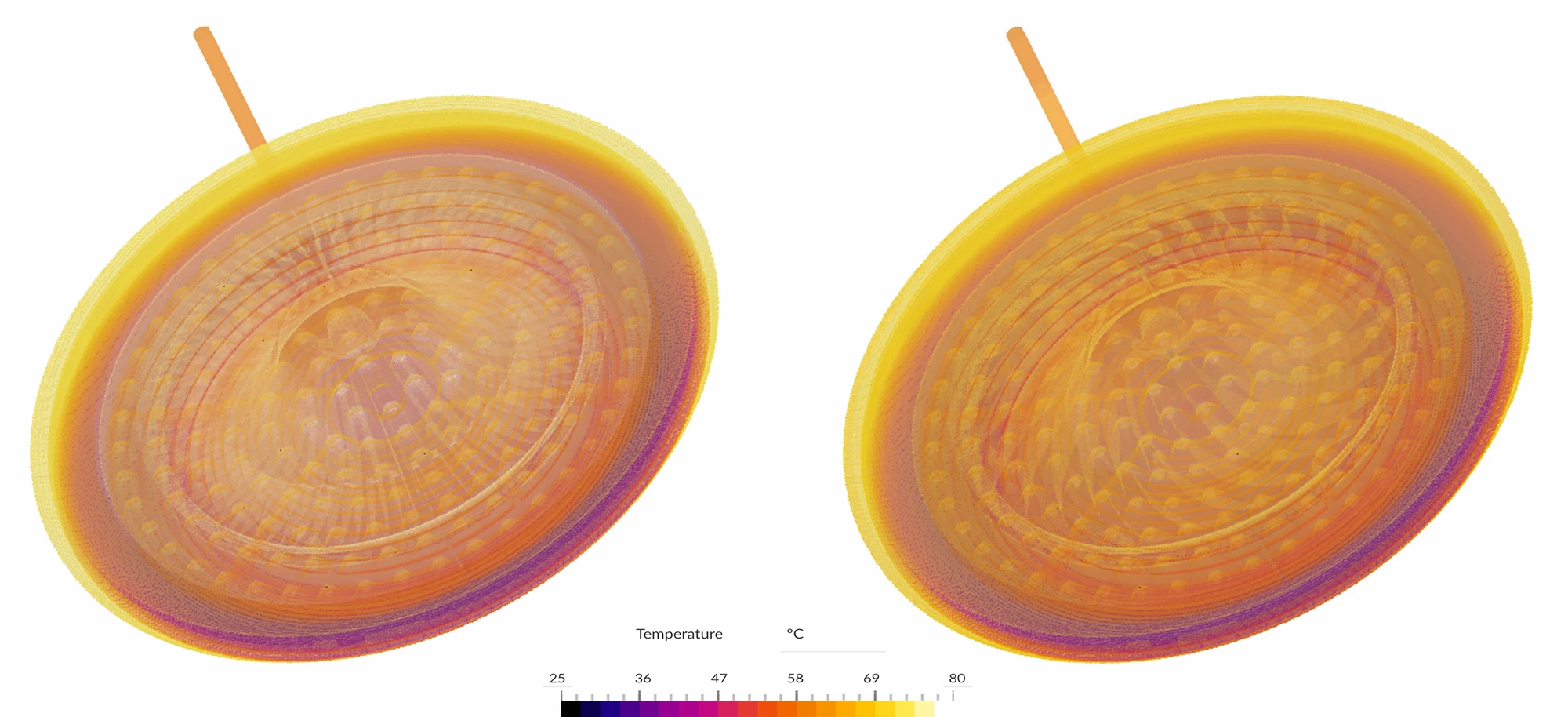

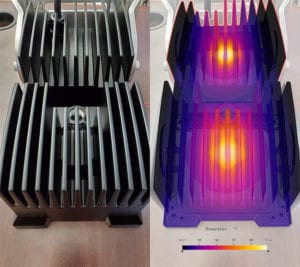

Omid and his team employed thermal analysis and Computational Fluid Dynamics (CFD) simulation using SimScale software to evaluate the performance of two heat sink designs in dissipating heat from the Luvo pendant lamp. The two designs included a heat sink with straight fins and a heat sink with a spiral fin layout, both made from die-cast aluminum. The simulation setup incorporated 84 LEDs as a heat source with a total heat load of 40 watts. The objective was to compare the effectiveness of these heat sinks in reducing the temperature within the LED lamp, which is crucial for maintaining efficiency, extending operational lifetime, and preventing potential failure. The performance and longevity of LEDs are highly dependent on effective thermal management. Inadequate heat dissipation can lead to increased junction temperatures, reduced efficiency and lifespan, and potentially lead to failure.

Two heat sink designs are considered:

Both proprietary designs are constructed from aluminum, a material with excellent thermal conductivity. The comparison aims to determine which design dissipates heat more effectively through natural convection. The CFD simulations are performed using SimScale, a cloud-based engineering simulation platform. The setup includes:

The simulations are used to generate insights into the temperature distribution and heat dissipation rates inside the LED lamp. LR could determine the better design with these simulation results:

The reduced temperature achieved by the spiral heat sink design ensures a more reliable operation of the LEDs. Lower temperatures correlate with higher efficiency, a longer lifespan, and a reduced risk of thermal-induced failures. The aluminum material is further evaluated using the extensive materials library in SimScale to consider alternatives. Reducing the overall weight and amount of aluminum used is important for cost efficiency and also the embodied carbon in the product, something lighting manufacturers including LR are increasingly conscious of.

Using SimScale we can now save weeks or even months in the design and development workflow – from concept over prototyping, testing, redesign, and retesting. The corresponding cost saving can be thousands of Euros for each of the design options for a product in development. The cumulative savings for a whole product pipeline are significant.

Lukas Pilat

Founder of Luke Roberts Lighting

“SimScale has saved our team cost and money as we don’t have to prototype every iteration or do a thermal test. We can simply refine the CAD design and simulate it because we are so confident in the simulation results. We simulate ten designs in parallel which we can do with SimScale being fully cloud-native making it faster and easier to use. Given we don’t need to invest in expensive hardware anymore, we have saved 50% on the cost of deploying a simulation platform in our engineering team and it’s driving our ability to continuously innovate.”

Omid Javanmardi Design Engineer at Luke Roberts Lighting. Omid is the lead mechanical engineer and thermal analysis specialist at Luke Roberts Lighting and was also the production manager for the Luvo pendant lamp.

Sign up for SimScale

and start simulating now