FanMechanics, operating under the registered business name H and R Resources, is a leading expert in designing, simulating, and sizing fans and rotating equipment. As a sole trader, the owner has established a reputation for providing expert software and design services to fan manufacturers. The company’s flagship product, Centrix, is a comprehensive tool that facilitates rapid fan selection, pricing, and drawing production. This case study highlights how FanMechanics utilizes SimScale, a cloud-based simulation software, to enhance its design and simulation processes, specifically focusing on computational fluid dynamics (CFD) applications.

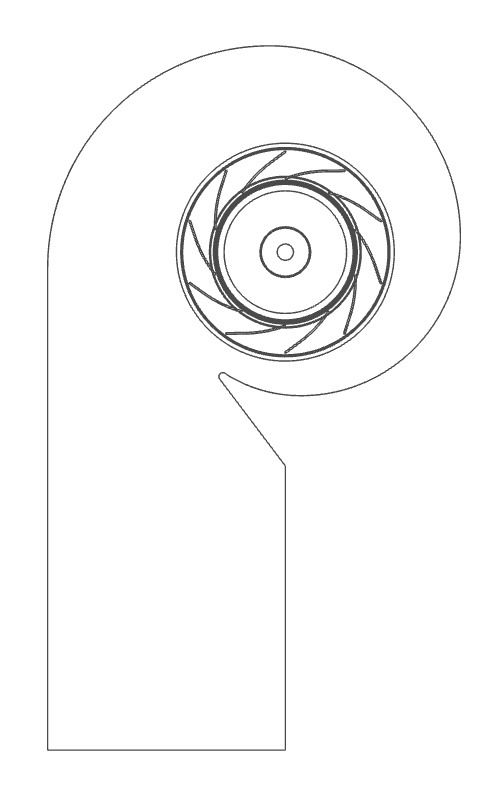

FanMechanics has a long history of centrifugal design and has made significant progress in the fan manufacturing industry. The company’s primary product stream, Centrix, is a robust software solution designed to assist fan manufacturers in quickly selecting fans, generating prices, and producing detailed drawings. The software incorporates various third-party modules for DWG and 3D model creation, making it accessible to a wide range of users.

Centrix, coded entirely by the owner Richard Knighton, is designed to streamline the fan selection process and provides:

Centrix outputs .dwg drawings compatible with most 2D drawing software and can export STEP and IGES files for import into other 3D CAD / CAE tools such as SimScale. Richard started using SimScale for computational fluid dynamics (CFD) simulation support for his established customer base.

The geometry requirements and speed of SimScale’s incompressible analyses are fantastic. I simply could not do these comparisons using TCFD on my AMD Ryzen Threadripper PRO 3975WX in an acceptable time. The difference would be many days instead of hours for SimScale. The Ryzen Threadripper is a dedicated PC for TCFD and Strand7 nonlinear analysis.

Richard Knighton

Owner of FanMechanics

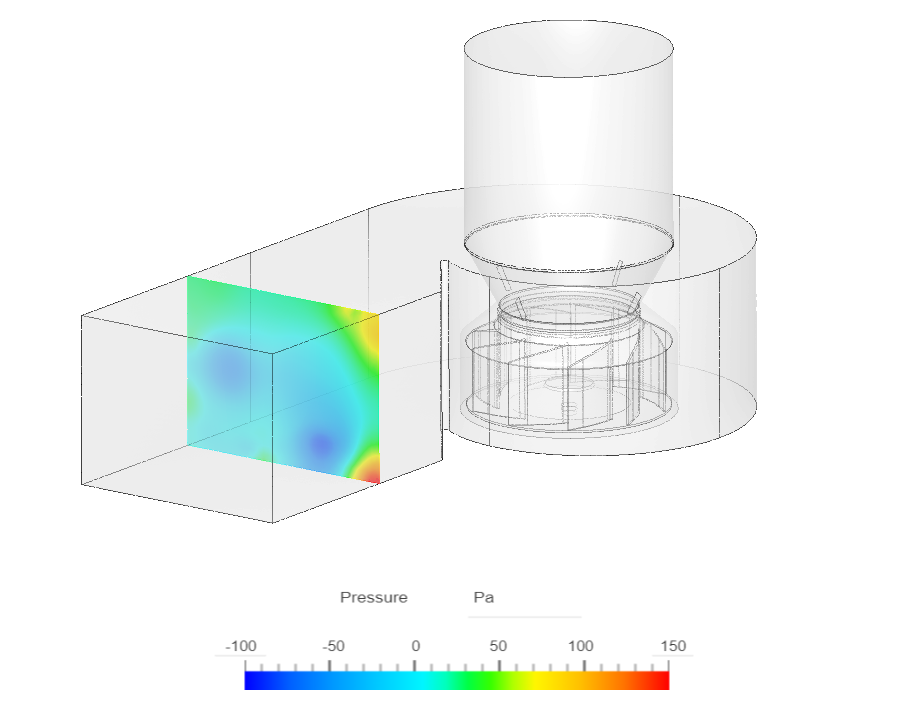

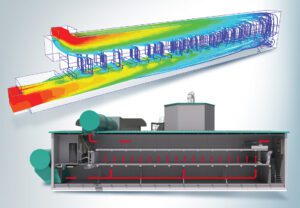

SimScale is a cloud-based simulation platform that offers a wide range of simulation capabilities, including CFD and FEA. FanMechanics primarily uses SimScale for incompressible CFD work, favoring it over other tools due to its efficiency and ease of use.

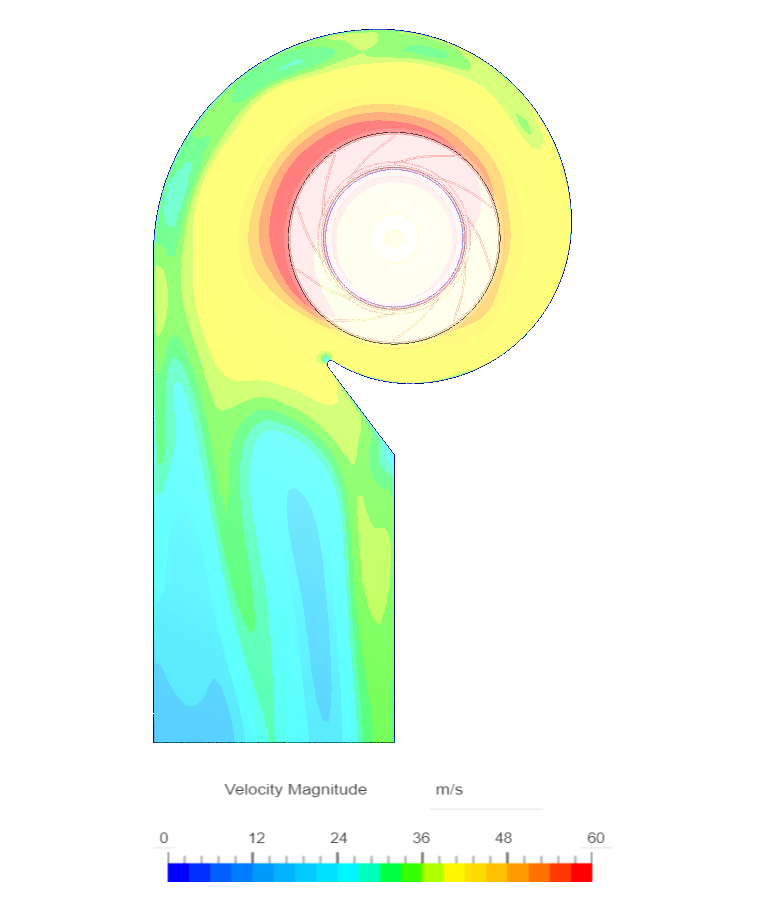

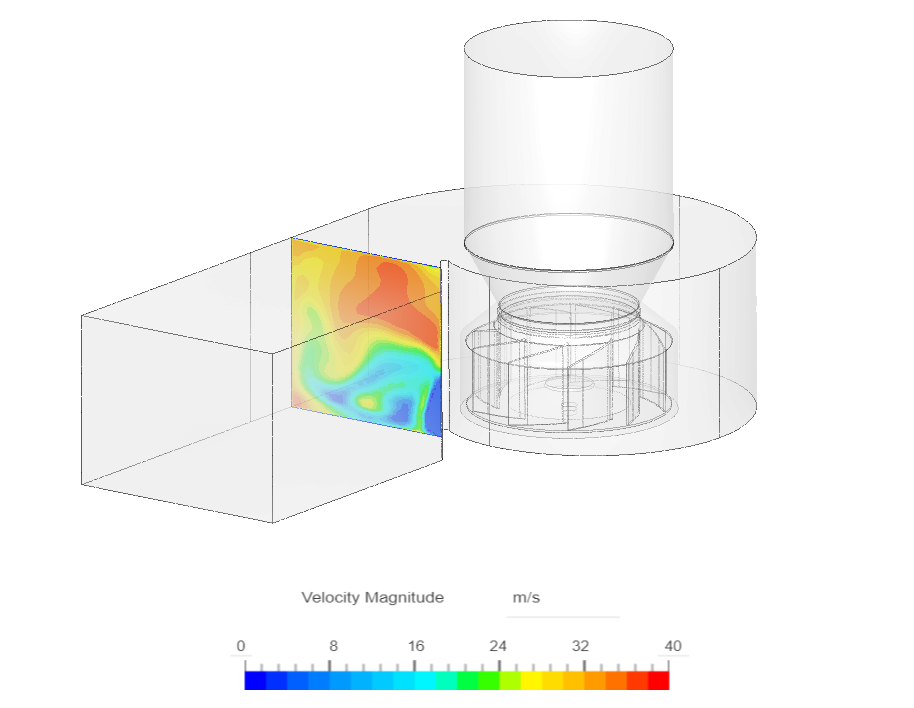

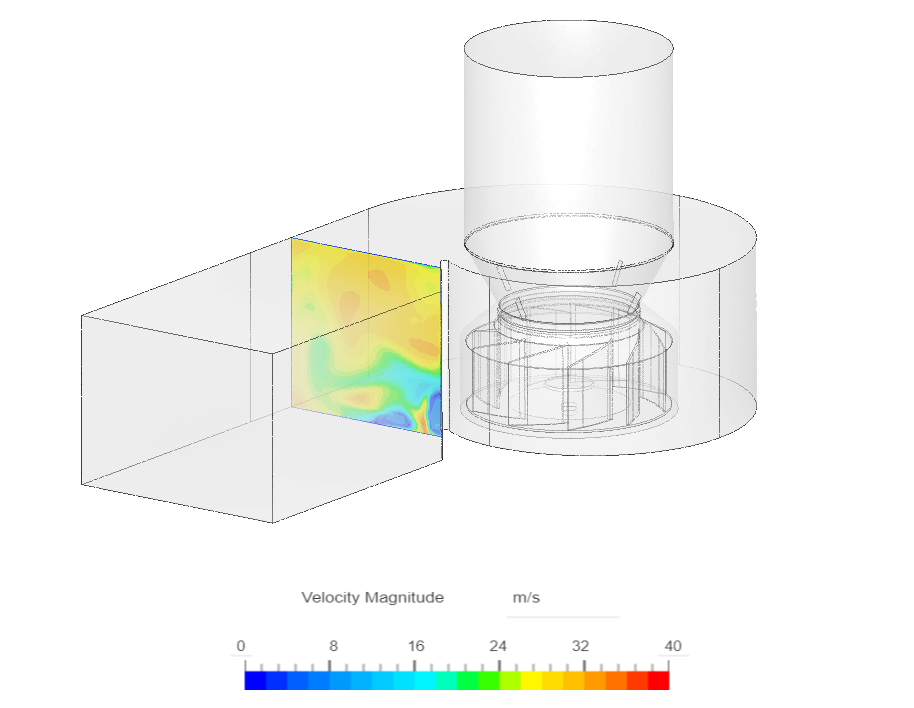

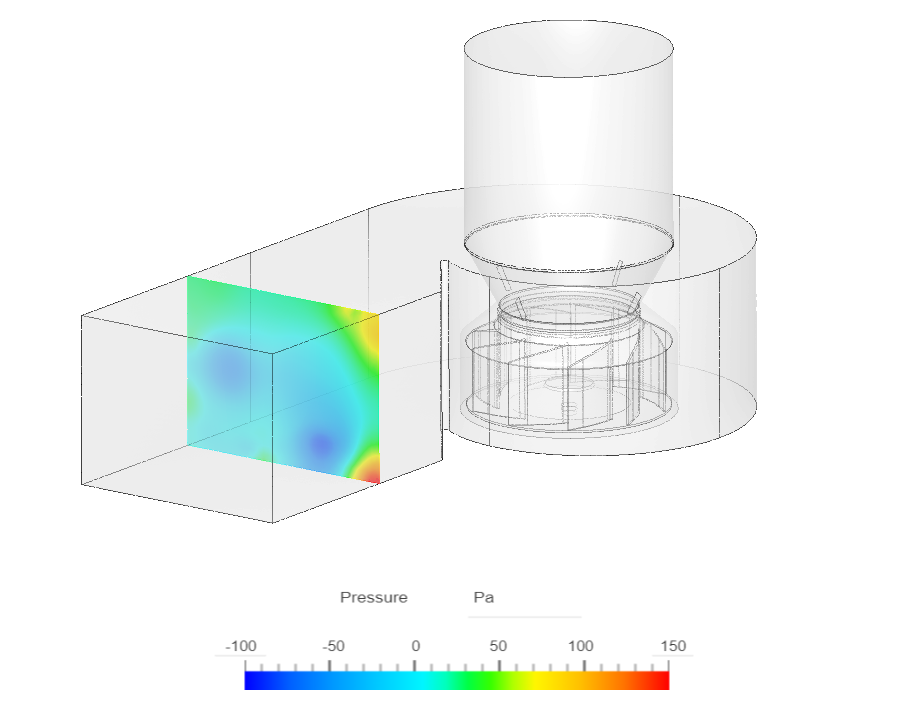

A client approached FanMechanics with the task of replacing an impeller and inlet cone in an existing centrifugal fan casing to improve flow and efficiency while maintaining the fan’s power consumption below 310 kW. The initial installation did not yield the expected improvements, prompting the need for detailed performance comparisons.

SimScale’s ability to simulate multiple CAD variants of a fan design in parallel has been critical in saving time and to quickly arrive at a converged design solution for my client.

Richard Knighton

Owner of FanMechanics

The simulations revealed key insights into the design modifications necessary to achieve the desired improvements. Using SimScale’s incompressible CFD capabilities, FanMechanics was able to:

SimScale’s cloud-based platform offers significant advantages in terms of speed and efficiency. The owner of FanMechanics notes that the geometry requirements and speed of SimScale’s analyses are superior to competitor software. The ability to run simulations in the cloud allows for continuous work on other tasks, streamlining the overall design process.

By utilizing SimScale, FanMechanics avoids the need for costly and time-consuming physical tests. The platform enables rapid iterations and comparisons, making it possible to refine designs based on accurate simulation data.

SimScale’s comprehensive suite of simulation tools supports the development of advanced fan designs. The ability to perform detailed CFD and FEA analysis ensures that designs are optimized for performance and reliability.

FanMechanics, through the innovative use of SimScale, has positioned itself as a leader in fan design and simulation. The cloud-based platform’s efficiency and versatility allow the company to deliver high-quality, data-driven design solutions to its clients. By integrating SimScale into its workflow, FanMechanics enhances its ability to provide rapid, accurate, and cost-effective services, solidifying its reputation in the fan manufacturing industry.

Sign up for SimScale

and start simulating now