Kohler Ronan is a leading, multi-disciplinary engineering consulting firm dedicated to providing exceptional mechanical, electrical, plumbing, fire protection, and technology design. The firm’s diverse team of over 70 professionals also offers energy analysis and commissioning services in-house from offices across the USA. Founded in 1998, the firm is now led by seven partners representing over 200 years of combined industry experience. Together, they collaborate with prominent architectural firms on a wide array of regional and nationally recognized projects. Recent work includes world-renowned museums, fine and performing arts centers, prestigious universities, state-of-the-art educational and healthcare facilities, luxury residences, premier recreation establishments, and modern corporate campuses. Additionally, they have designed specialty systems for landmark sites and historically significant buildings across North America.

In all projects, Kohler Ronan seeks to design sustainable building systems which enhance occupied spaces and are socially and environmentally responsible. The firm is proud of its extensive expertise and innovative approach in the field of sustainable design and is a member of the US Green Building Council (USGBC). Nearly 20 of their engineers are Leadership in Energy and Environmental Design Accredited Professionals (LEED AP), while other relevant professional certifications include Building Energy Modeling Professional Certification (BEMP) and Living Future Accreditation (LFA), as well as Fitwel Ambassador, Well AP, and Certified Passive House Designer (CPHD) designations. The diversity and depth of their expertise which combines building physics, environmental design, and sustainability makes them an invaluable member of any project team.

Kohler Ronan is dedicated to a low-carbon future and is a member of the Carbon Leadership Forum (CLF)’s MEP 2040 Challenge. As a signatory, the firm is committed to “advocate for and achieve” net zero operational and embodied carbon by 2030 and 2040 respectively, across all its projects. Kohler Ronan is an expert in applied building simulation and physics tools which are routinely used to evaluate green building design options for orientation, envelope/fabric, fenestration, shading, and indoor air quality.

Commonly applied energy and thermal modeling (zonal) tools are used to perform annual energy rating assessments and load calculations. They can also offer simplified indoor air temperature predictions that feed into the larger energy model. For more detailed simulations where the airflow inside a space (sub-zonal) data is required, more sophisticated computational fluid dynamics (CFD) software such as SimScale is required. This is especially critical for full-height spaces, those with complex air movements, spaces with a high proportion of glazing, and/or very niche indoor comfort and ventilation requirements. Kohler Ronan turns to SimScale for modeling ventilation, indoor thermal comfort, and thermal stratification analysis in theaters, concert halls, and complex spaces.

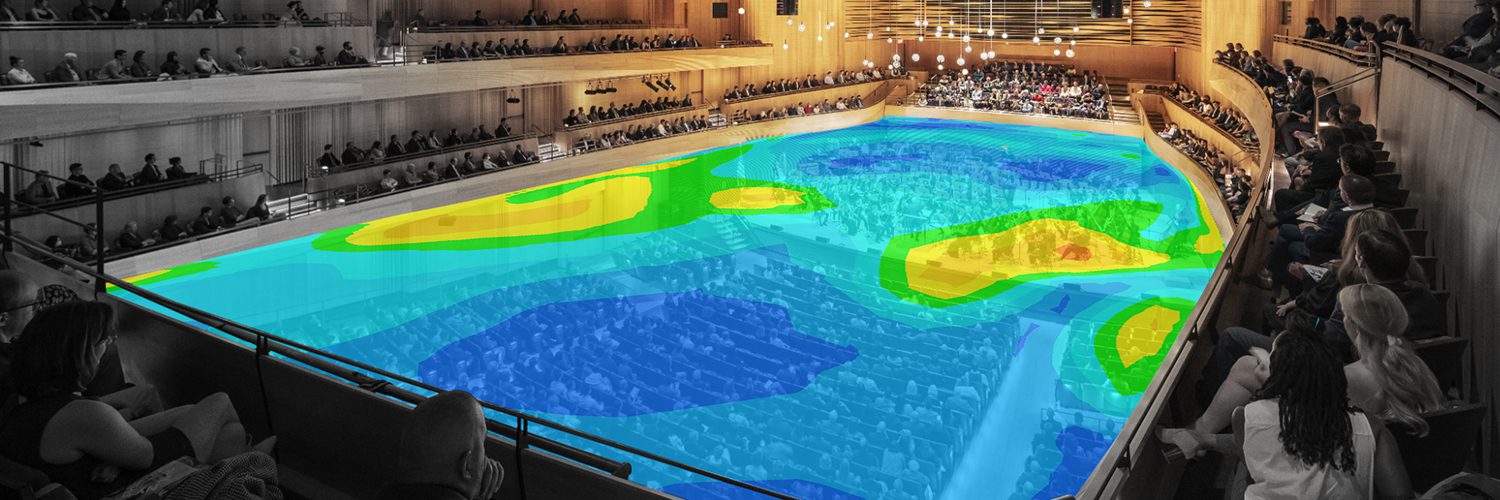

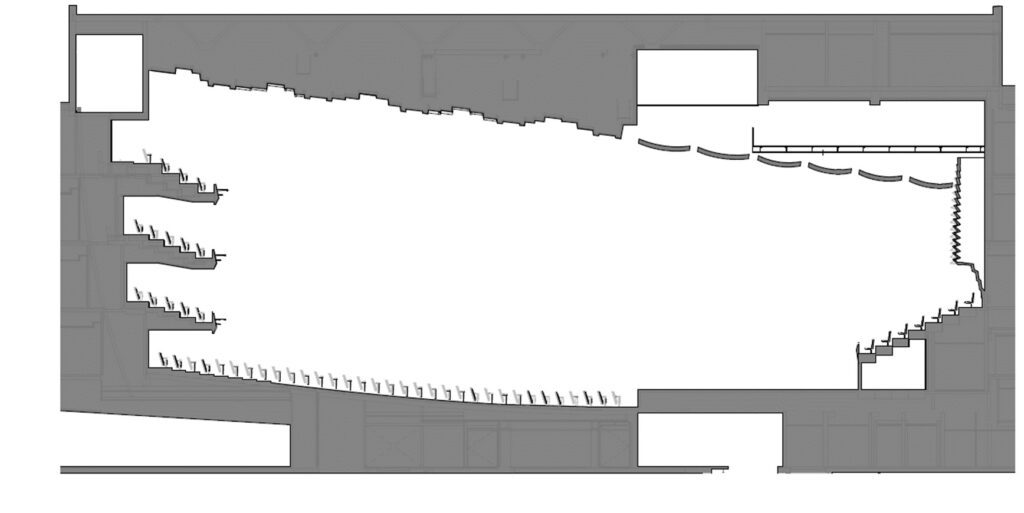

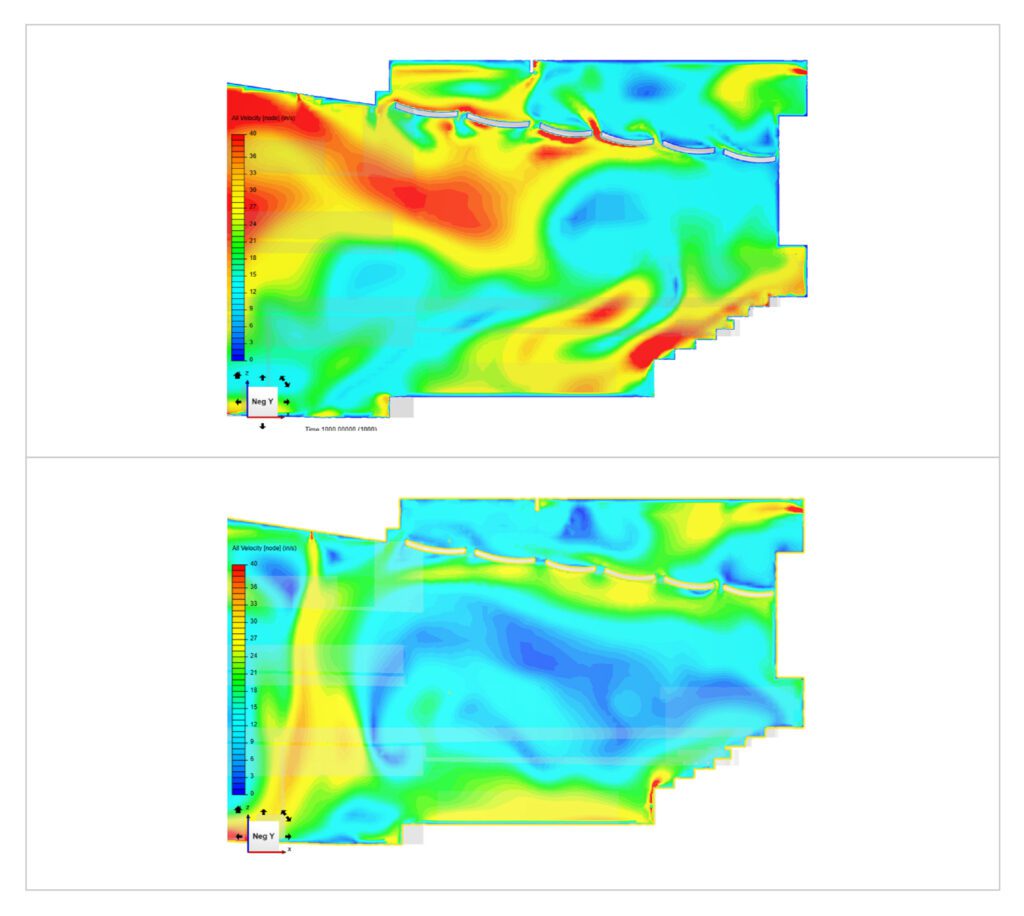

The ventilation & comfort assessment and redesign of David Geffen Hall at Lincoln Center (New York City, USA) stands out as a landmark project. Having long complained about previous cold drafts and poor thermal comfort, as well as suboptimal acoustics in the original building layout, the project owners commissioned Kohler Ronan as M&E consultants. To evaluate these issues in detail, Kohler Ronan used SimScale for internal simulations of airflows and temperatures as an iterative process whilst considering various design options for a new and improved ventilation and acoustic redesign of the hall. The key outputs were temperature and velocity gradients for the different auditorium modes including concert (symphonic), graduation, and stage performances.

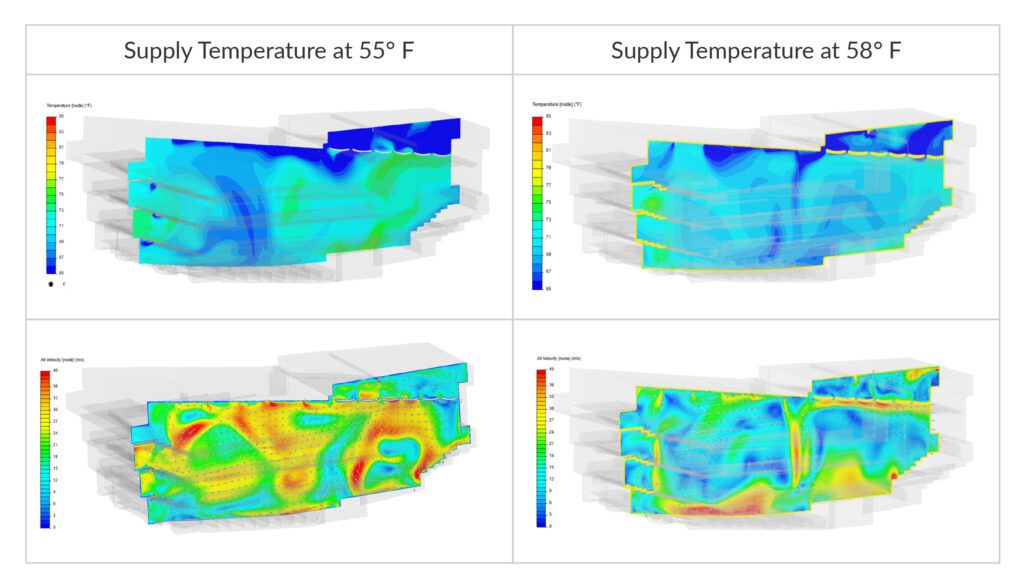

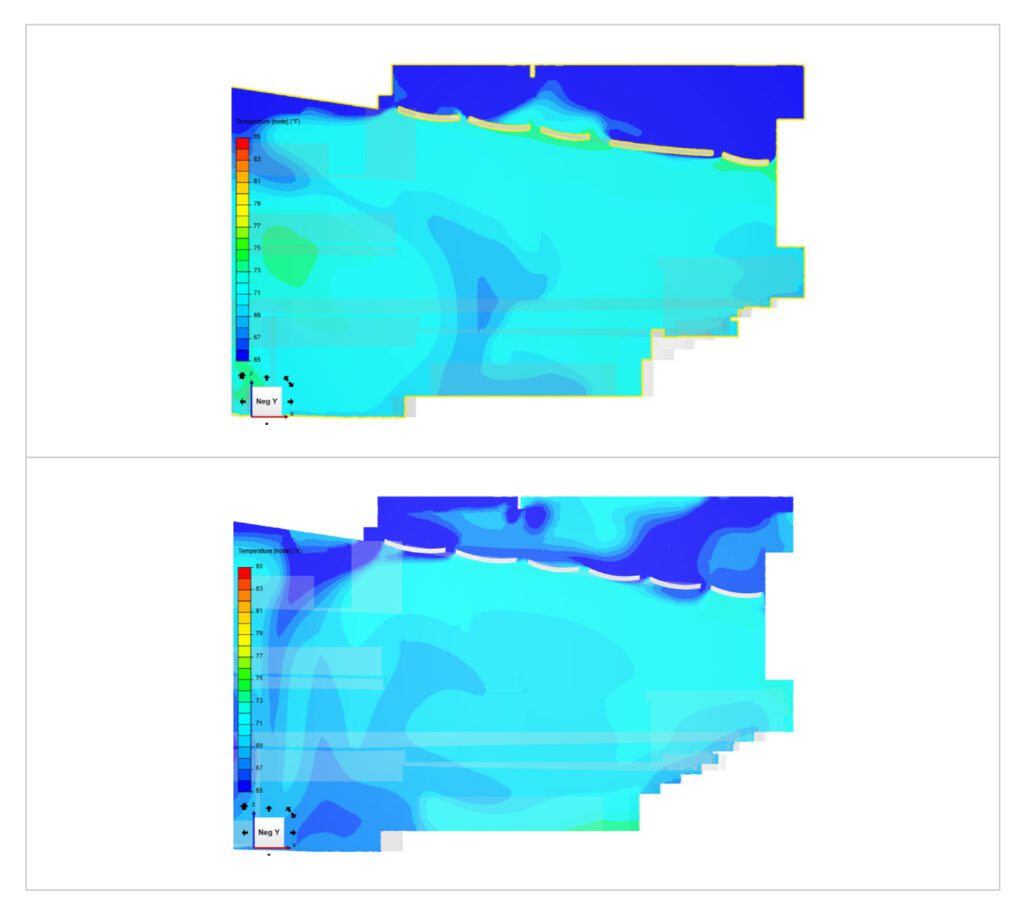

The results of CFD simulations were fed into the load/ventilation sizing calculations for chillers and boilers. As the hall has an extremely large volume, ventilation had to be provided from the top, sides, and floors to meet the required fresh air and ventilation rates, and to ensure adequate thermal mixing for comfort purposes. At a set point supply temperature of 55° F, they observed cold spots and unsatisfactory thermal comfort. For better comfort, the supply temperature was increased slightly to 57-58° F, well mixed, and consistently achieved to provide less stratification and better air mixing. Similar results were recorded for the main stage areas. Velocity gradients, which are expected because of temperature differences and stack effects in large spaces, were minimized by carefully increasing the supply temperature.

The existing building already had pathways for ductwork and supply/extract fans, thus limiting any ventilation strategy to these constraints. Analysis showed that the engineers needed to move the ventilation supply from the front of the theater toward the back to ensure better mixing. This move would also ensure an increased acoustic performance and avoidance of downdraughts. Additional flexibility for multiple-stage configurations was yet another benefit of this change in layout.

On-site measurements were conducted using air velocity and temperature sensors. The comparison shows that the measured results are close to the simulated results. However, the simulation reflects a new design condition and cannot be compared directly to the existing condition. The CFD also does not reflect the roughness of materials and physical objects which would further slow down airflow in the space.

Kohler Ronan was able to come up with key design takeaways from the study that was implemented:

The main benefit of using SimScale is the ability to link advanced computational fluid dynamics in the cloud to energy savings from our thermal modeling and analysis. Optimizing for comfort in sensitive spaces like large theaters with significant structural and acoustic constraints is a difficult task, and having access to the right tools at the right time is critical to ensure building performance.

Madhav Munshi

Mechanical Engineer at Kohler Ronan

Learn more in this webinar with Kohler Ronan and see how computational fluid dynamics (CFD) in the cloud can be used to design for ventilation, air quality, thermal comfort, and other environmental variables in large and complex spaces including.

Sign up for SimScale

and start simulating now