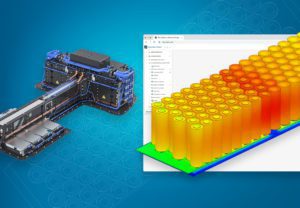

As a large organization with multiple distributed engineering teams, Kichler is moving towards adopting an entirely cloud-based engineering software stack. This will improve both top-line and bottom-line results, including faster product innovation and lower hardware and software costs. Kichler engineers working on product design and testing have benefitted from embedding early-stage simulation into their workflows. This includes a significant reduction in physical prototyping costs, time-saving from seamless CAD to simulation setup, and a fuller design space exploration leveraging parametric modeling capabilities. An upstream cloud CAD tool, Onshape, allows for fast integration with SimScale and both have excellent collaboration features. Kichler has been partnered with Onshape for more than five years and its main purpose has been to help us work continuously with globally distributed teams and share updated files and data. It also allows Kichler to be flexible with their international supplier base by easily updating documentation without significant manual file sharing.

Josh Levine, Lead Engineer in the value engineering department at Kichler, is tasked with continuously identifying cost savings. Josh and his team were tasked with optimizing an LED heat sink design by reducing component material mass whilst maintaining thermal performance.

The total material cost saving was 44%. We eliminated testing and prototype costs on this project entirely. It usually takes 1-3 weeks of prototyping time and another 1-3 weeks for all the testing normally done. Overall this project was successful and it helped achieve our goal of reducing cost and keeping within the project timeline.

Josh Levine

Lead Engineer in Value Engineering Department at Kichler Lighting

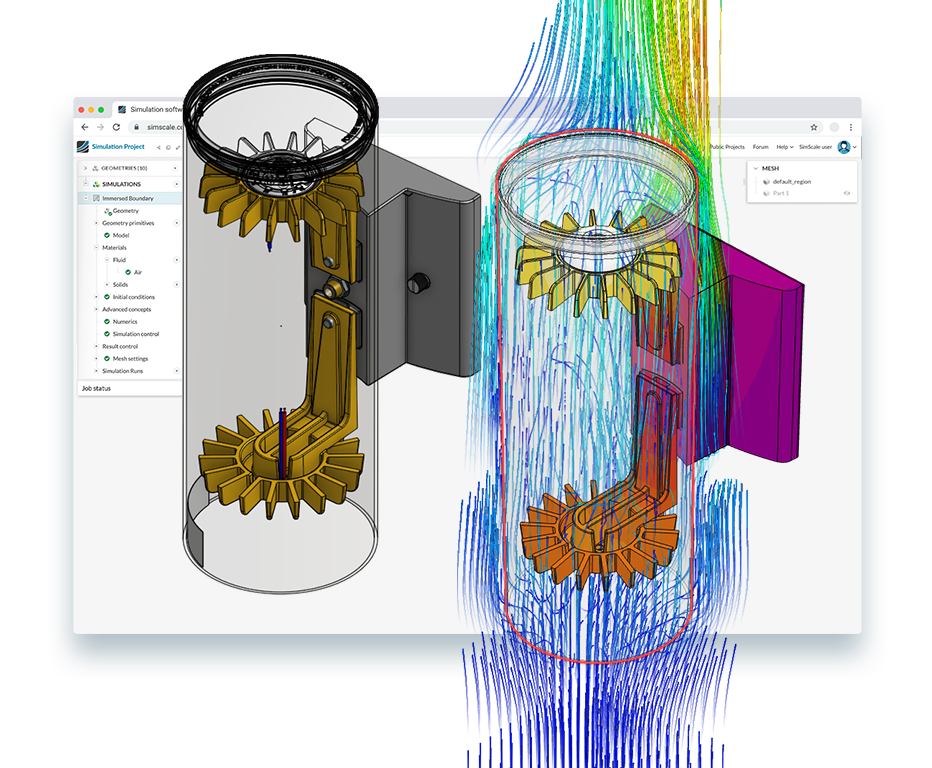

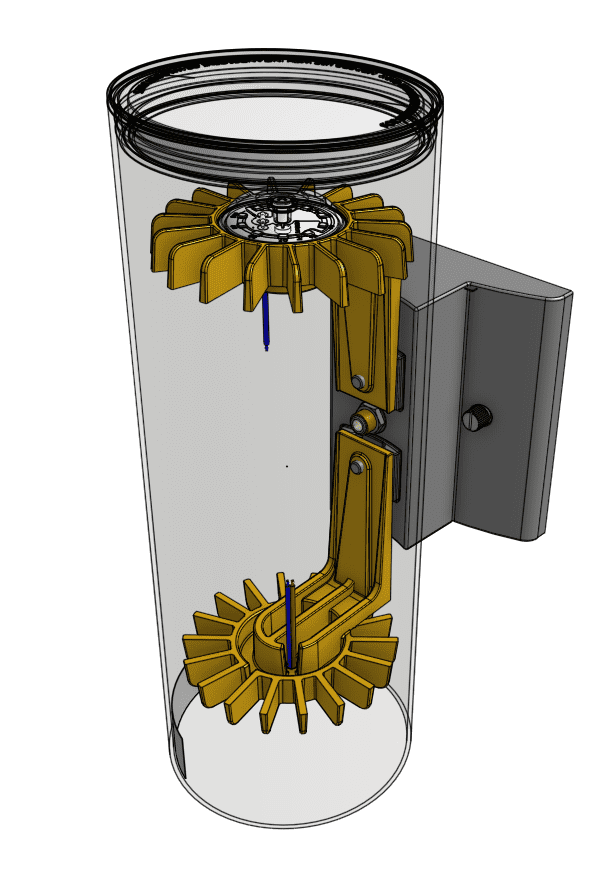

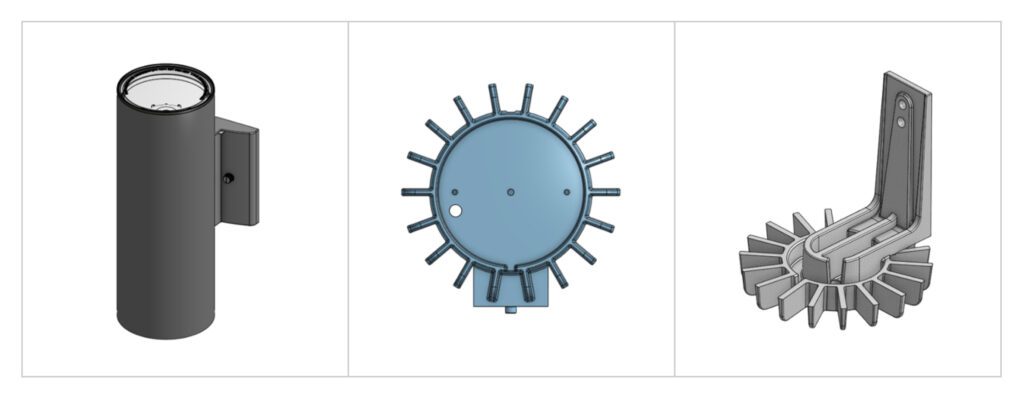

The objective of the study was to reduce the unit cost of each heat sink by reducing its material weight. Due to strict project timelines which don’t allow for prototyping and testing time on significant iterations, reducing development time was also a goal. Using SimScale, Kichler performed various geometric alterations on the heat sink model and used heat transfer and CFD simulations to quantify its thermal performance. The current outdoor LED wall sconce (fixture) in the image below was the product under consideration.

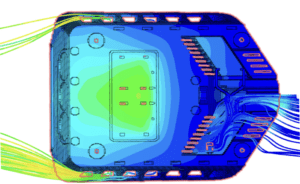

The component parts of the LED model are shown in the table below and the aluminum heat sink is to the right with a volume of 58,000 mm3. One design change that impacted this project was the switch from a DC driver to an AC Onboard driver which caused an increase in module size leading to an increased platform on the heat sink as well as greater heat generation from the driver inside the main cylinder. Two areas of particular concern were inside of the module lens and outside of the module, leading to the canopy/mounting enclosure. Kichler was willing to sacrifice some thermal efficiency from the heat sink as long as it did not compromise other component thermal constraints for this product, including:

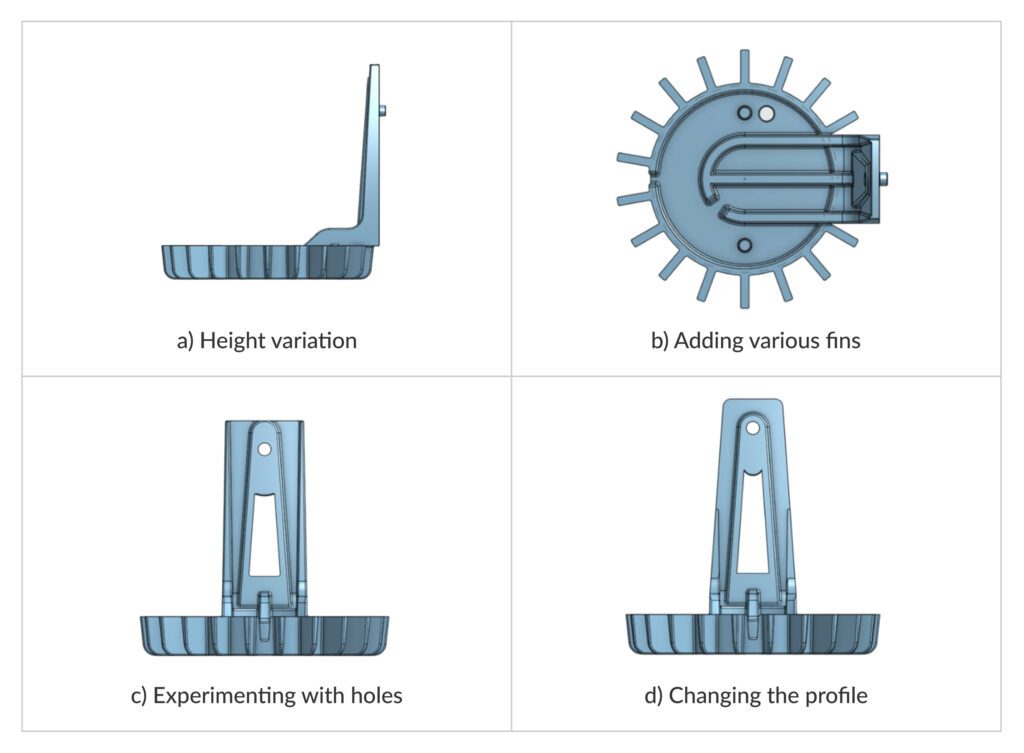

Kichler created a baseline model (control sample) to evaluate relative improvements against. Several variations of heat sink design were proposed including:

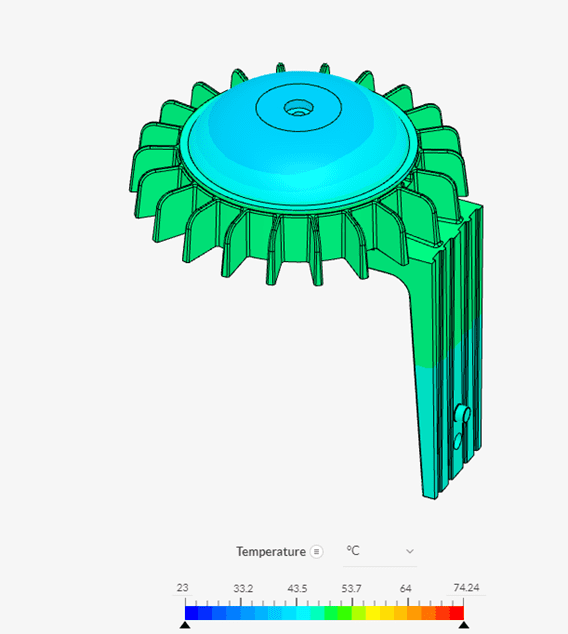

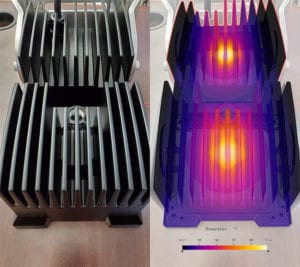

To start this project, Kichler created a baseline prototype of a new design which was used as a control sample. They simulated the prototype and found the simulated temperature readings were within a 6° C tolerance of what they might expect which was considered adequate. This initial prototype was the first design iteration and had a reduced volume of 3,000 mm3 via channels on the back of the heat sink giving a max heat sink temperature of 74.24° C and an outside module temperature of 44.4° C.

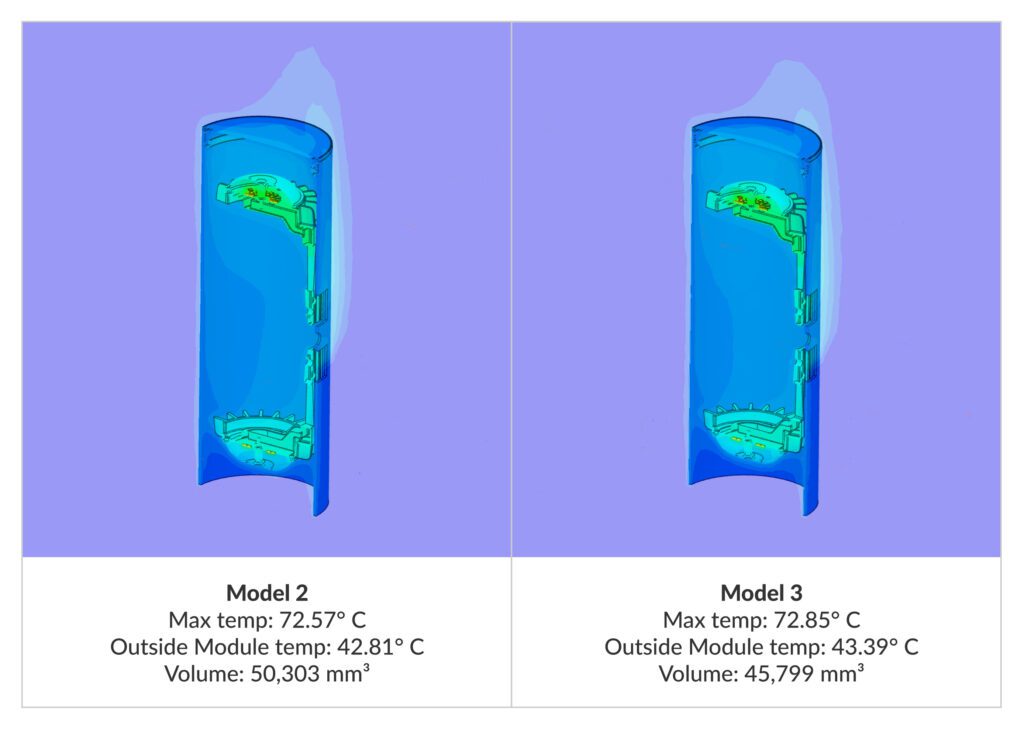

Kichler wanted to reduce the component material weight further and designed more variations. The images below show some of the results from different models. The key takeaways are:

Volume continuously dropped for each model – from 58k to 50k and then to 45,800 mm3

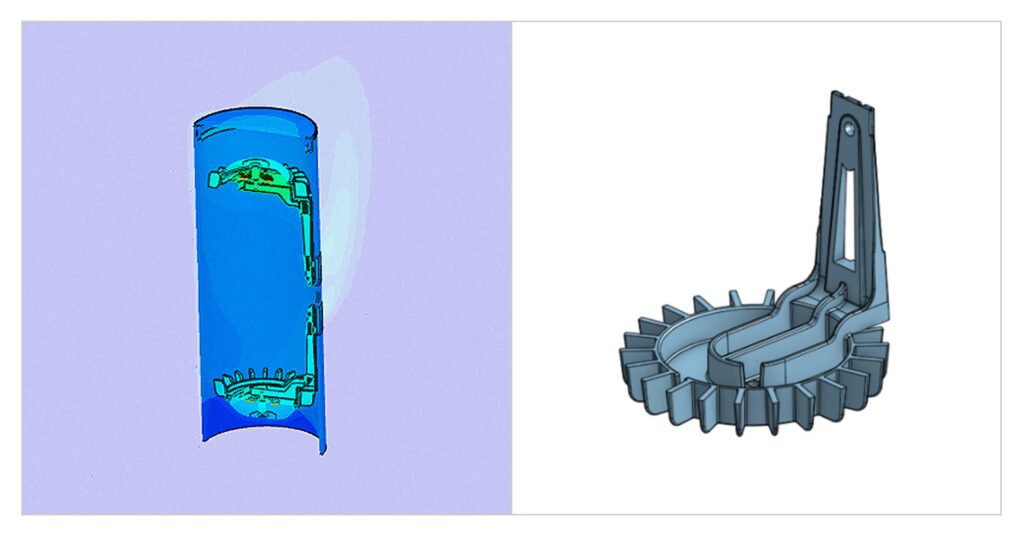

The final model yielded slightly higher temperatures than the control sample but still below the product constraints even when adding back 10-15% for simulation discrepancies. The total volume for the final model was 32,800 mm3 and given that two heat sink components are in each fixture, that adds up to 51,300 mm3 in savings or 139 grams of aluminum per LED fixture. The current final model is being fine-tuned to make it manufacturing-ready.

In summary, a 44% component material saving was achieved through the use of SimScale and the workflow eliminated the numerous prototyping costs entirely, saving up to 3 weeks of time for creating the physical prototypes and another 1-3 weeks in laboratory testing. The next step for Kichler is to deploy the value engineering through a simulation approach across other product lines.

The customer support team is extremely helpful and quick to respond. We’ve been able to speed up our learning curve by communicating heavily with the SimScale team while creating simulations. They review our projects in real time and provide feedback as we make improvements.

Josh Levine

Lead Engineer in Value Engineering Department at Kichler Lighting

Sign up for SimScale

and start simulating now