The team at Katapult Design are industrial designers and product development experts who transform designs into iconic products. They believe that design solutions should be elegant in resolution, innovative in function, and compelling in appearance. Katapult Design is a leading global product design and development consultancy with studios in Melbourne, Sydney, and Byron Bay, Australia. Katapult Design develops products in a broad range of categories including medical, consumer, sports tech, and industrial products by leveraging engineering simulation with SimScale.

Katapult Design offers a comprehensive range of design services, spanning industrial design, mechanical engineering, and product strategy — all underpinned by a robust development process including the use of finite element analysis (FEA) and prototyping.

SimScale’s FEA capabilities have proven invaluable for Katapult’s design outcomes. The team

uses structural analysis simulations to quickly evaluate material selection and design

optimization. By iteratively simulating multiple material and loading scenarios, Katapult gains

insights that drive design decisions. For example, Mani describes a project where they analyzed

glass-filled polymers as an alternative to aluminum parts, reducing weight and improving

efficiency for their end client.

By testing variations in geometries, Katapult refines designs for optimal performance. It is not

uncommon, for example, to have a geometry with multiple design iterations simulated with

multiple materials and loading scenarios. This quickly scales to dozens of simulations, all of

which can be run in parallel in the cloud whilst keeping desktop computing resources free for 3D design — usually a computational resource-heavy CAD software. SimScale’s agility allows them to make data-driven decisions earlier in the design process which improves confidence and results throughout the design process.

We found the workflow intuitive and easy to achieve meaningful results in a short time span, ideal for

the consulting environment we work in.”

Mani Balasubramaniam

Industrial Design Engineer at Katapult Design

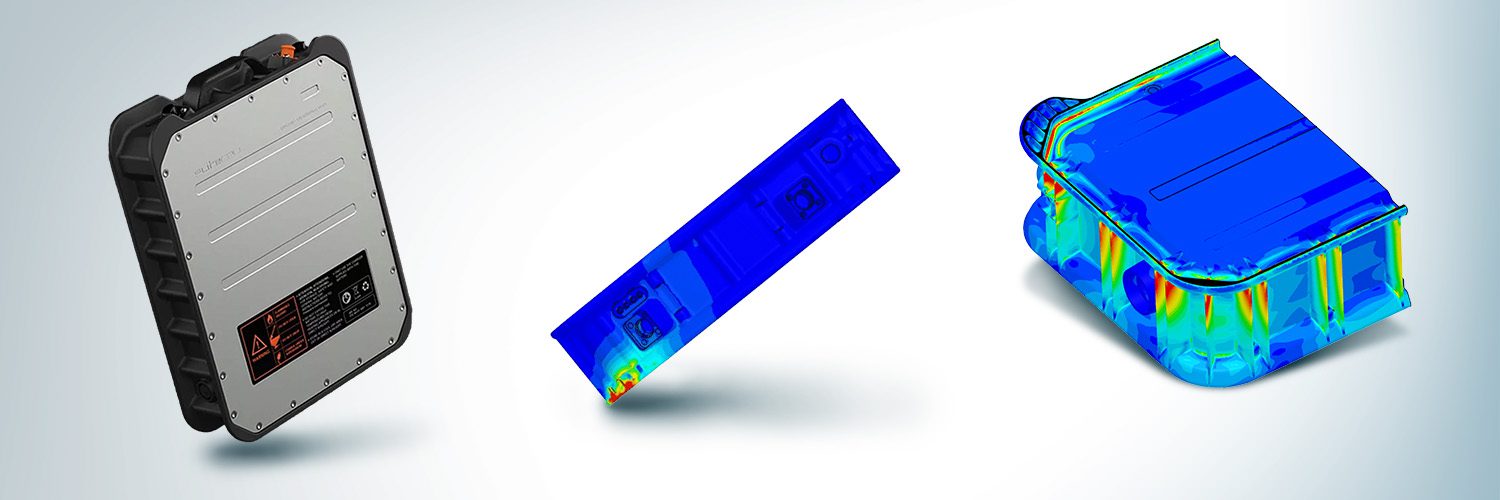

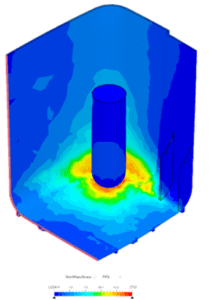

The eFoil hydrofoil surfboard developed by Fliteboard is engineered for high performance, ease of use, and durability. One of the most powerful features is its unique lithium-ion battery that powers the propelled versions of the eFoil.

The Flitecell Nano is the world’s lightest lithium-ion eFoil battery. It has been carefully developed to deliver the right amount of power and endurance whilst being sensitive to the balance and maneuverability required when gliding on the water. It’s designed to be closer to the mast and contributes minimal swing weight for a more stable ride and its design has been refined using simulation at every stage.

The Flitecell Nano technology is a durable portable marine battery that contains Phase Change

Materials (PCM), which absorb and release energy. PCM provides enhanced thermal management, safety, and longevity for the battery system. It contains the same premium quality 21700 cells utilized in high-power applications such as hypercars, providing durable performance. Titanium plates make Flitecell highly corrosion-resistant while increasing impact resistance for structural integrity. The battery unit provides 806 Wh of storage capacity, giving a foil time of 45 minutes.

It would be difficult to have a workstation laptop powerful enough to run FEA simulations concurrently

whilst working with large assembly CAD files. That’s why simulation in the cloud is so useful. We can

run numerous simulations on a design whilst 3D modelling the next iteration we want to simulate in

parallel — the rate of development we can achieve is impressive.

Mani Balasubramaniam

Industrial Design Engineer at Katapult Design

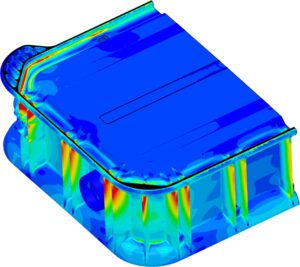

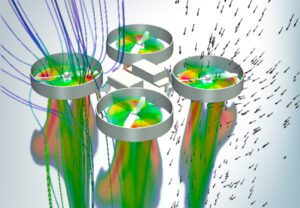

To achieve the unique design and performance requirements for the Flitecell Nano battery, Katapult ran FEA simulations in SimScale. Their main objective of using FEA was to optimize wall sections to reduce the weight of the battery. They also changed from a titanium/plastic sandwich construction of the battery to reduce weight — one of the titanium lids was removed and incorporated into the plastic housing instead. Running simulations gave the designers confidence that these design changes would not compromise the strength of the battery whilst meeting weight and cost reduction requirements. The battery was also required to pass drop impact testing to evaluate its structural integrity. Because of its unique material composition, a physical 3D prototype was unfeasible. Katapult chose to run dynamic simulations instead, using SimScale.

SimScale’s user-friendly interface and intuitive nature have made FEA accessible to our team. Katapult leverages SimScale for cost-effective product design, especially for quick-turn, cost-sensitive projects. The cloud-based access and seamless integration into the design process enhance the team’s efficiency, enabling them to run simulations while working on other demanding tasks.

James Burns

Design Director at Katapult Design

Sign up for SimScale

and start simulating now