“Aqseptence Group is a leading global supplier of specialized products, equipment and system solutions for filtration & separation and water technology for various applications. Aqseptence Group unites some of the most renowned brands of the industry, serving industrial and municipal customers for more than 100 years. Johnson Screens is one of the key brands of Aqseptence Group, and is well-known for developing screens in industrial filters, water wells, and architecture.

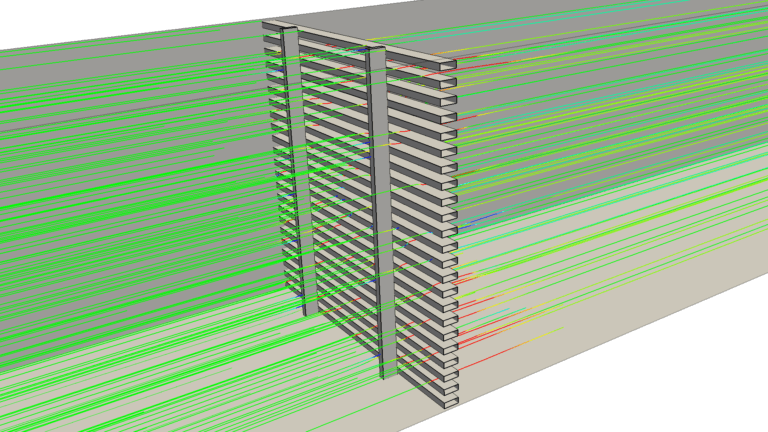

The Research and Development department at Johnson Screens received a project estimator request from the Architecture Sales group for an airflow analysis of their architectural radiator grille product that would be used in a high-profile skyscraper in New York.

Their goal was to make sure that the grille did not induce too much pressure drop into the ventilation system. A high pressure drop would translate to bigger blowers and higher energy consumption. It was important to their customer to keep the energy consumption at a minimal level.

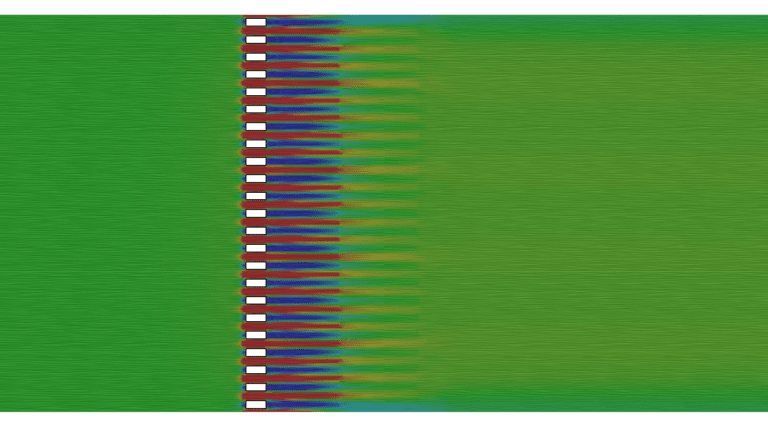

Daryn Bertelson, CAE Engineer in the Research and Development department at Johnson Screens of Aqseptence Group, wanted to visualize the air velocity contours and determine the pressure drop across the grille. This way, he wanted to ensure that the company could offer their customer a modern, clean, and professional looking grille while at the same time helping the customer to conserve energy for the building.

To get the same results with a physical test, it would take us months and would cost anywhere from $7k to $15k, even for this project, which is actually very small in scope. With SimScale, we could just run a virtual test at the office which took only 18 minutes.

Daryn Bertelson

CAE Engineer at Johnson Screens – Aqseptence Group

First of all, it is almost impossible to imagine exactly how the airflow is affected by the grille without a computational fluid dynamics analysis. Using SimScale allowed Johnson Screens of Aqseptence Group to accurately model the airflow and take scientific measurements of air velocities and pressures at precise points in space in the vicinity of the grille.

For this project, Daryn used a fluid dynamics incompressible flow simulation with k-omega SST – steady state turbulence model, on a hex-dominant automatic “wind-tunnel/external flow” coarse mesh with inflated boundary layers. “Although it can be a little tricky to get the mesh right, SimScale offers a good mix of automatic mesh generation with the ability to make custom adjustments with a multitude of settings,” mentioned Daryn.

Daryn was able to use 1 million discretized volumes to make the calculations. SimScale handled this number of calculation volumes without a problem. This particular simulation converged with 220 iterations or “steps” and took only 18 minutes to run.

According to Daryn, “this is incredibly fast for such a large number of calculations.” Daryn ran quite a few simulations, with each configuration only just a little different from the other.

“The nice thing about SimScale is that you can essentially run an unlimited number of simulations simultaneously with no reduction in computational resources, because SimScale opens up each simulation on independent nodes. This is a huge advantage for us, because we are typically under heavy time constraints.”

With the help of SimScale, the Research and Development department at Johnson Screens of Aqseptence Group was able to find an accurate measure of the pressure drop, provide professional flow contour visualizations to their customer, and show that they are leaders in flow analysis technology.

One interesting part of their results was that they found out how much the lower support bars of the radiator grille actually affected the flow distribution. When they initially performed hand calculations, they excluded these effects. However, the simulation showed them that excluding these effects could, in some cases, lead to misleading results.

Daryn estimated that in order to get the same analysis with a physical experiment, his company would need approximately 7-15 thousand dollars and a few months of time.

Aqseptence Group is planning to launch a global training program to expand their CFD/FEA usage to all engineering groups within the company across multiple locations and product lines. As part of this initiative, they are setting up an enterprise framework of SimScale around three primary focus areas: templates for standard configuration products, shared models for global projects, and training where more experienced users can assist new users with the creation of a model even across different locations.

Sign up for SimScale

and start simulating now