LUMENION GmbH is a high-temperature thermal storage company whose mission is to store low-cost renewable energy and deliver heat to industry, agriculture, and private homes. LUMENION is a decarbonization company offering a solution for zero-carbon industrial-grade process heat. With today’s technology, it is possible to make effective and efficient use of renewable energy anywhere in the world. The high-temperature energy storage system by LUMENION allows wind and solar PV-generated electricity to be used with a highly efficient heat storage solution.

LUMENION offers a high-temperature thermal energy storage system (TES) that stores fluctuating wind and solar PV power as thermal energy at very high efficiency. This thermal energy can be released and used at a later time as process heat or for district heating. The system offers a significant increase in efficiency and lower costs for industrial heating processes that are notoriously difficult to decarbonize. LUMENION has an ambition to play a key role in advancing the energy transition in the heating (and cooling) sector. This is important as up to two-thirds of industrial energy used is for heat, mainly process heat.

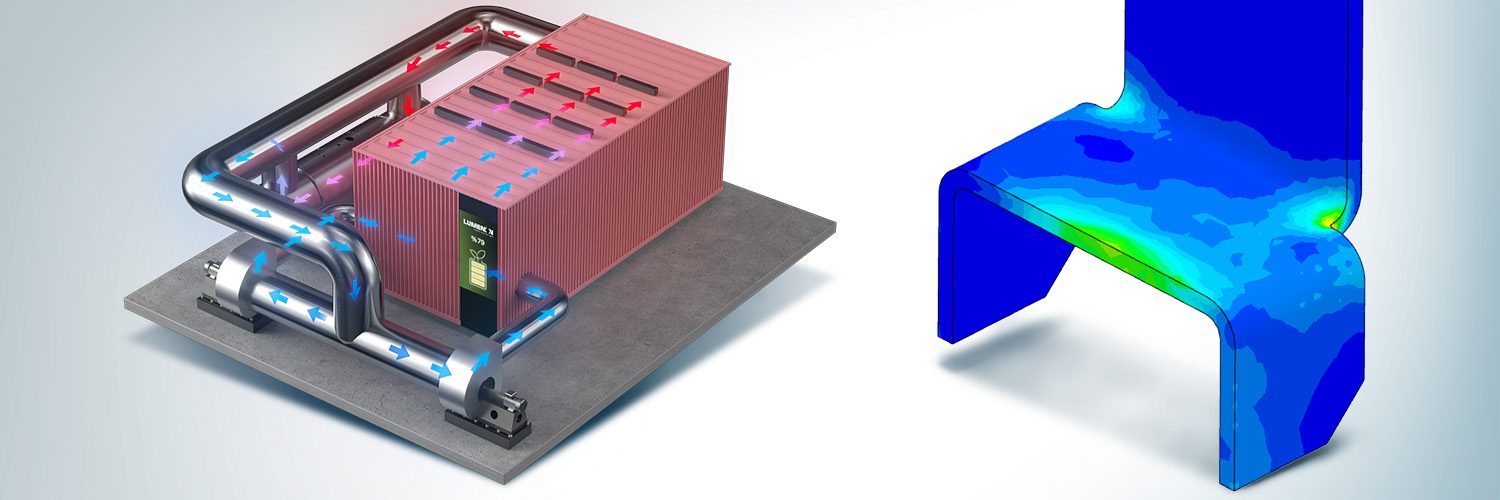

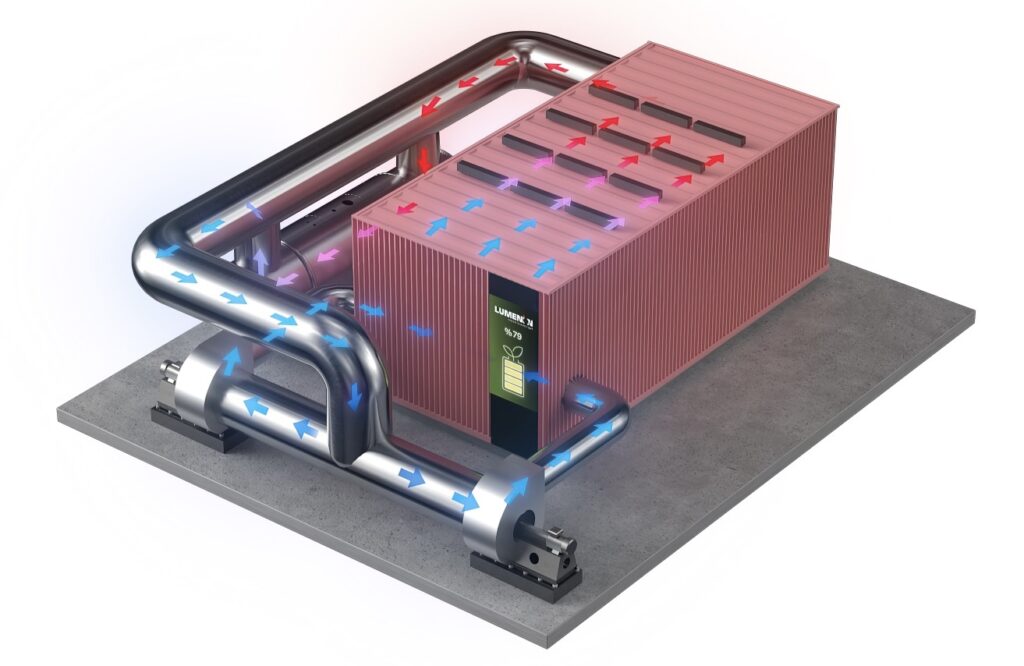

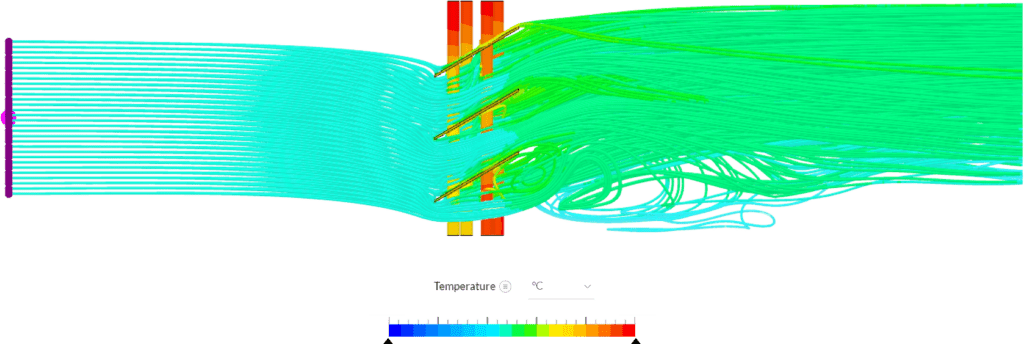

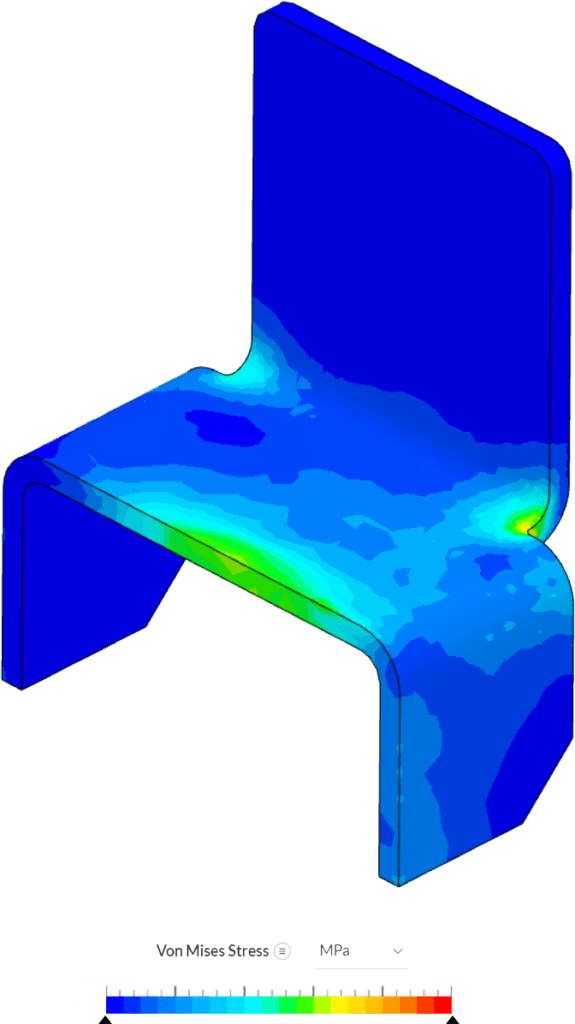

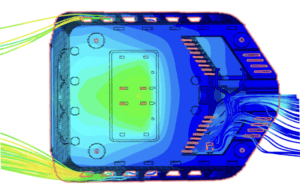

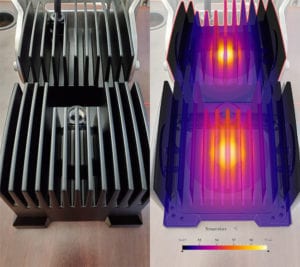

For the larger scale plant, all the design simulations were carried out in SimScale. This included the heat transfer effectiveness of the steel core, air transfer optimization through ducts, calculating heat losses, and even structural lifting loads for safety purposes.

Param Jolly

Energy Engineer specializing in energy storage. At LUMENION, he works on the realization of an ideal thermal energy storage and leads the company's Research & Development team.

The TES is a power (electricity)-to-heat technology based on the idea of sector coupling. Wind and solar PV power are deployed for charging first before switching to the grid. The storage unit converts cheap electricity generated during peak output periods into a reliable and steady supply of thermal energy. By coupling the electricity and heat supply-demand scenarios, the TES achieves up to 95% efficiency. Simultaneous charging and discharging ensure maximum availability and optimizes resource usage. The TES can be charged in four to six hours—spread over a day or continuously, for example, during off-peak periods when the grid is not heavily used and electricity prices drop.

An electrical resistance heater converts the electricity into heat which is transferred by an air circuit into the highly dense steel core of the storage unit. The core is made of steel elements that can be heated to as much as 600° C and store this heat with marginal losses of less than 5% per day. Thermal energy can be discharged whenever it is required. The same air circuit transfers the stored heat to a heat exchanger which supplies process heat (water or thermal oil) between 150° C and 400° C, or process steam between 150° C and 350° C, for any application. The process is similar for cooling applications. The modules at the core of the system are made of structural steel which has numerous benefits:

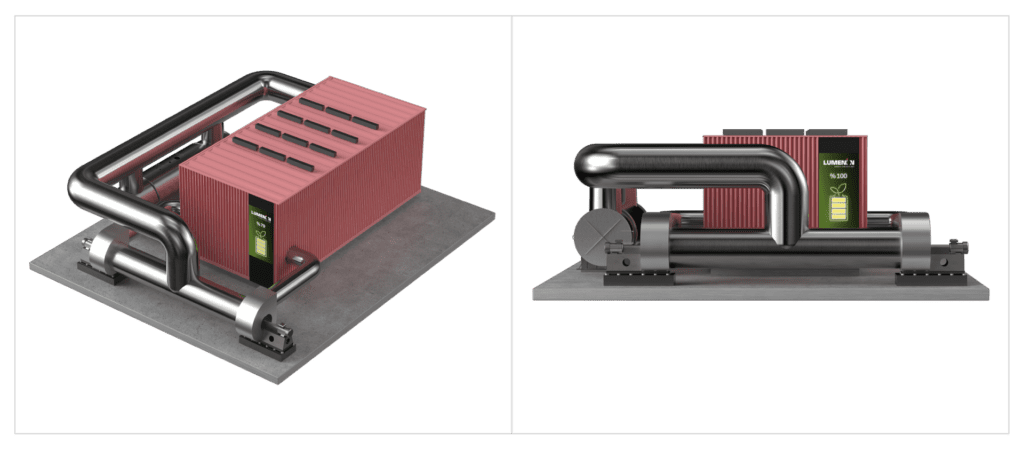

A prototype unit is installed in Berlin with a capacity of 2.4 MWh for residential heating in Bottroper Weg and is the first commercial unit installed. LUMENION is completing a new project in northern Germany with a rated capacity of 20 MWh thermal with a charging power of 5 MW electric. The location is favorable being surrounded by grid-connected wind turbines which are used to supply electricity to the plant.

The 20 MWh TES is currently under construction for one of the largest food manufacturers in Europe, WESTHOF BIO, who will use the heat in their energy-intensive food processing plants. Again, the electricity input to generate the heat comes from renewable sources. The heat is used throughout the day as relatively cheap renewable electricity charges the thermal storage. The unit has an electrical charging power of 5 MWel and produces 207° C saturated steam and can be discharged over a wide range from 6 h to 18 h, depending on the load demand.

The engineering team at LUMENION uses SOLIDWORKS as their main CAD tool. Importing geometry into SimScale has never been easier using the SimScale SOLIDWORKS add-in and the SimScale API which is used to customize and automate workflows and results analysis. LUMENION can test 100 different geometries from SOLIDWORKS in SimScale using the API to manage the simulation inputs and documentation. This has saved them considerable time and cost, and they have recently upgraded to a team plan with SimScale giving them even more administrative and simulation management features.

LUMENION TES is a complex system with many critical components including the steel core, ducts, fans, pumps, pipes, valves, coolants, electrical heaters, and steam generators. The system operates at very high temperatures and is considered critical for safety purposes in a highly regulated power and utilities industry. The steel core is a labyrinth heat exchanger core made of structural steel. The core can be completely charged in four hours and based on demand can have slow/fast discharging depending on the load demand. The easily available, high-temperature industrial fans blow air through the system to transfer hot air from the core to the steam generator which converts water to steam. The overall system is 95% efficient with 5% standby losses per day and an operating efficiency of 90%.

Each component has to be carefully simulated against real-world scenarios and then the whole system performance must be modeled to replicate various conditions. Examples of analysis types LUMENION performs using SimScale include:

Pratik Kalsariya is a Simulation and Calculation Engineer at LUMENION and his main area of research is the analysis of concept models for the creation of detailed designs in the field of high-temperature thermal energy storage systems. He has run simulations on more than 300 different design variants for the steel core — all using SimScale.

Because of the computational resources of the cloud, and the parallel simulation runs coupled with CAD associativity in the SOLIDWORKS add-in, I was able to simulate a combination of flow and structural analysis at low cost. The simulation results from SimScale were corroborated by independent physical testing from an expert third-party, giving us even more confidence in the SimScale results. The hard work has resulted in over 16 patents for our unique thermal energy storage system.

Pratik Kalsariya

Simulation and Calculation Engineer at LUMENION

Sign up for SimScale

and start simulating now